Definition of thick wall aluminum tube

In aluminum alloy tubing, the distinction between thick-walled and thin-walled tubes is typically based on the ratio of wall thickness to tube diameter. Specific standards can vary depending on the industry and application, but generally, there are several methods used for classification

| Wall thickness to outer diameter ratio method This is the most common method, based on the ratio of wall thickness(t)to outer diameter (D)(t/D): Thick-walled tube: t/D > 0.1 (meaning the wall thickness is greater than 10% of the outer diameter). Thin-walled tube: t/D ≤ 0.1 (wall thickness is less than or equal to 10% of the outer diameter). | Absolute wall thickness method This method categorizes tubes based on their absolute wall thickness, which may vary depending on the material and application: Thick-walled tube: Typically has a wall thickness of 5 mm or more. Thin-walled tube: Typically has a wall thickness of less than 5 mm. | Industry standards and specifications Different industries and countries may have specific standards and specifications for defining thick-walled and thin-walled tubes. Engineering and construction standards often specify exact wall thickness ranges for these tubes. Specialized sectors like aerospace and automotive also have their own standards for defining tube thickness. |

Aluminum thick wall tube hot selling stock size

Aluminum tubes are generally divided into thick wall and thin wall types based on their wall thickness. When the wall thickness exceeds 10% of the outer diameter, or is greater than 5 mm in absolute terms, it is considered a thick wall aluminum tube. MASTAR provides a variety of thick-walled aluminum tubes with wall thicknesses typically ranging from 0.012 inches to 0.200 inches. Quick Quote

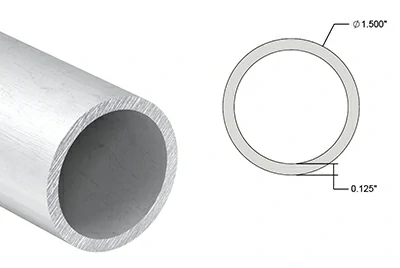

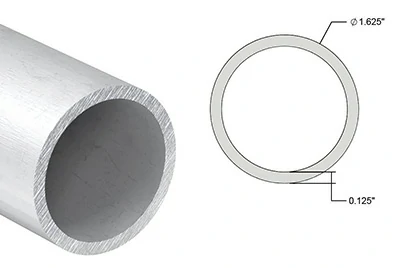

- 1-1/2'' OD* 0.125'' WLL Thick Wall round tube

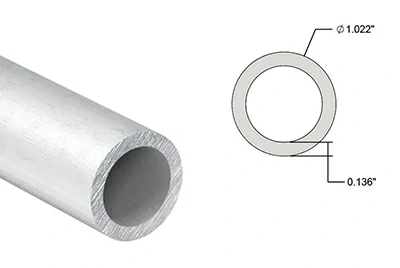

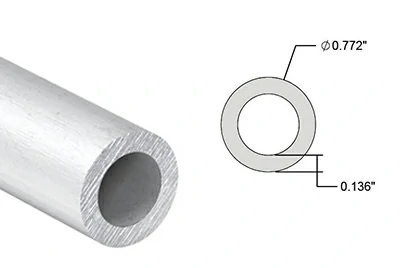

- 1'' OD*0.136'' WLL Thick Wall round tube

- 1-3/8'' OD*0.136'' WLL Thick Wall round tube

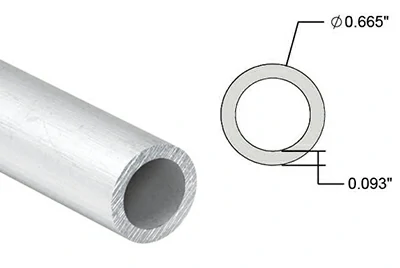

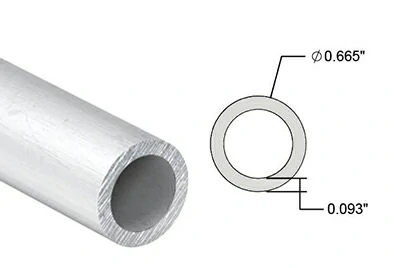

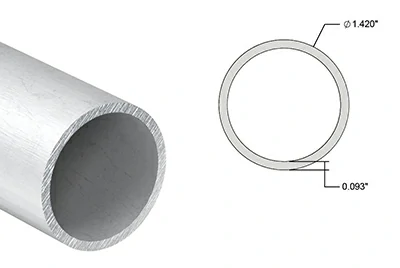

- 11/16'' OD* 0.093'' WLL Thick Wall round tube

- 15/16'' OD*0.093'' WLL Thick Wall round tube

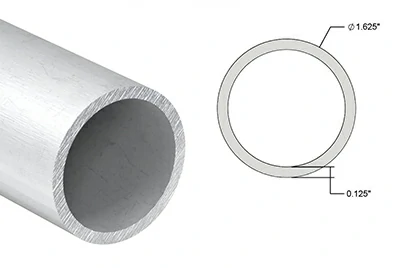

- 1-5/8'' OD*0.125'' WLL Thick Wall round tube

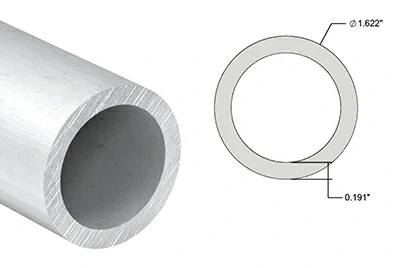

- 1-5/8'' OD* 0.191 WLL Thick Wall round tube

- 11/16'' OD* 0.093'' WLL Thick Wall round tube

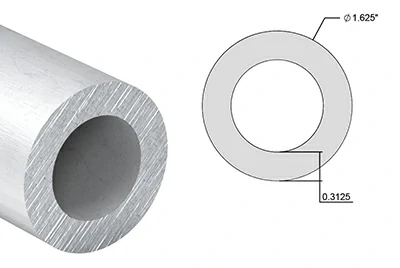

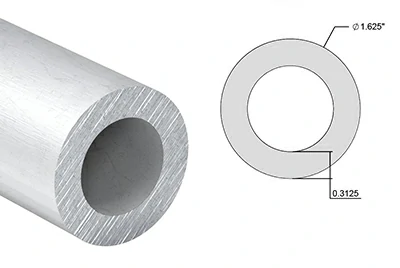

- 1-5/8' OD* 0.3125'' WLL Thick Wall round tube

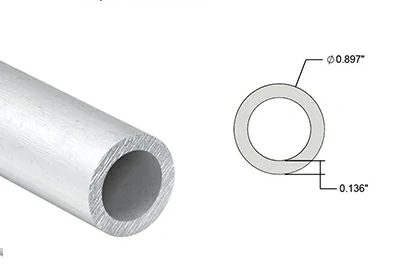

- 7/8'' OD* 0.136'' WLL Thick Wall round tube

- 3/4'' OD* 0.136'' WLL Thick Wall round tube

- 1-7/16'' OD* 0.093WLL Thick Wall round tube

- 1-5/8'' OD* 0.3125'' WLL Thick Wall round tube

- 1-5/8'' OD* 0.125'' WLL Thick Wall round tube

Aluminum thick wall tube hot selling alloy products

MASTAR thick-walled aluminum tubes come in various shapes: round, square, ring-shaped. Depending on the shape requirements of your application, you can explore our standard round, square, and rectangular aluminum tubes, all available with thick-wall configurations. The most commonly used aluminum alloys for these thick-walled aluminum tubes are 6061 and 6063. These aluminum alloys have proven to be flexible, weldable, and convenient. MASTAR offers thick-wall tubes in a variety of alloy grades, including 6061, 6063, 6082, and 7075 aluminum, each tailored for specific mechanical or environmental requirements.

- 6061 aluminum thick wall tube pipe

Medium strength, good corrosion resistance, excellent machinability. Applied in aerospace, automotive parts, building structures, sports equipment, and more.

- 6063 aluminum thick wall tube pipe

Excellent extrudability, medium strength, good overall mechanical properties. Applied in architectural profiles, decorative components, household items, industrial piping, and more.

- 6082 aluminum thick wall tube pipe

High strength, good corrosion resistance, excellent machinability and weldability. An ideal material for various industrial and engineering applications, including structural components, transportation, mechanical manufacturing, marine engineering, aerospace, and industrial equipment, among others.

- 7075 aluminum thick wall tube pipe

High strength, poor weldability, good fatigue resistance. Applied in aerospace structural components, high-strength parts, sports equipment, military hardware, and more.

- 2024 aluminum thick wall tube pipe

High strength, good machinability, excellent fatigue resistance. Applied in aerospace structural components, high-stress parts, automotive components, and more.

- 5083 aluminum thick wall tube pipe

Excellent corrosion resistance, good weldability, medium strength. Applied in shipbuilding, marine engineering, chemical equipment, storage tanks, pressure vessels, and more.

- 5052 aluminum thick wall tube pipe

Good corrosion resistance, medium strength, excellent machinability and weldability. Applied in transportation equipment, architectural decoration, storage tanks, pressure vessels, and more.

- 3003 aluminum thick wall tube pipe

Good corrosion resistance, relatively low strength, excellent weldability. Applied in air conditioners, refrigerators, automotive radiators, kitchen utensils, and more.

Featured products of MASTAR aluminum thick wall tube

- Thick-wall aluminum unthreaded pipe nipples and pipe

- Thick-wall butt-weld aluminum unthreaded pipe fittings

- Thick-wall aluminum threaded pipe nipples and pipe

- Thick-walled aluminum telescopic pipe

- Porous thick-walled pipe

- Large diameter thick-walled pipe

Looking for more specialized tube types? MASTAR also offers a variety of threaded, perforated, and telescopic aluminum tubes to meet advanced structural or connection requirements.Quick Quote

MASTAR aluminum thick wall pipe product service areas

High strength and load-bearing applications

High strength and load-bearing applications- High-pressure vessels, hydraulic and pneumatic systems, structural support components, etc.

- Due to their greater wall thickness, possess higher strength and load-bearing capacity, enabling them to withstand greater internal and external pressures and mechanical loads.

Impact resistance and wear resistance applications

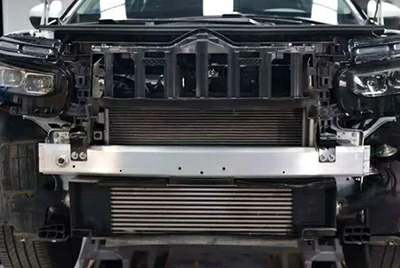

Impact resistance and wear resistance applications- Mining equipment, heavy machinery, automotive crash beams, etc. The increased wall thickness of thick-walled tubes enhances their ability to resist external impacts and wear, maintaining good performance even in harsh environments.

Heat conduction applications

Heat conduction applications- Industrial radiators, cooling systems, heating equipment, etc. Despite the greater wall thickness, aluminum alloys inherently have good thermal conductivity. Thick-walled tubes can still effectively dissipate heat, making them suitable for equipment requiring heat dissipation.

Fatigue resistance applications

Fatigue resistance applications- Aerospace, automotive manufacturing, bridge and building structures, and other areas requiring long-term load bearing. The greater wall thickness improves the tube's fatigue resistance, making it less prone to fatigue damage under cyclic loading.

Corrosion resistance applications

Corrosion resistance applications- Marine engineering, chemical pipelines, oil and natural gas transportation pipelines, etc. Aluminum alloys inherently have good corrosion resistance. Thick-walled tubes can maintain a longer service life in corrosive environments, suitable for use in harsh conditions.

Stability and durability applications

Stability and durability applications- Building support structures, heavy equipment components, transport vehicle frames, etc. Thick-walled tubes have higher stability and durability when under stress and during use, less prone to deformation and damage.

While thick-walled aluminum tubes are ideal for high-strength, high-pressure, and long-term load-bearing scenarios, thin-walled aluminum tubes may be better suited for weight-sensitive or cost-controlled applications.

To help you choose the most appropriate solution, we've prepared a dedicated guide comparing thick wall vs thin wall aluminum tubes, covering structural performance, machining needs, and industry applications.

Choosing MASTAR aluminum thick-walled tubes

- Quick delivery: we maintain a comprehensive inventory, ensuring rapid shipment of any standard aluminum profile, saving time for your project's smooth progress.

- Custom profiles: in addition to standard tubes, MASTAR can provide custom tubes according to customer requirements for dimensions and finishes. You only need to specify the alloy, length, quantity, surface finish, end-use, and any other special requirements. For more details on available sizes, shapes, and alloy options, please check our full aluminum tube product range.

- Competitive pricing: our products are competitively priced, and we offer reasonable discounts for large-volume orders, allowing you to obtain more favorable prices and better service.

- After-sales support: we provide prompt after-sales support, ensuring you receive timely assistance and support when using our products.