1060 aluminum bar is a high purity aluminum alloy with excellent electrical conductivity and corrosion resistance, widely used in power, electronics, construction and transportation. Its main features include good processability and low density, making it very popular in the manufacture of lightweight structures and electrical components.

1060 aluminum bars can be produced by hot rolling, cold drawing or extrusion processes with uniform properties and dimensional accuracy. Due to its excellent electrical conductivity, it is particularly suitable for applications such as power distribution and heat exchangers, which can effectively transfer current and heat.

MASTAR 1060 aluminum bar product introduction

Size: 5 mm to 500 mm; click to view detailed [Size Table]

Length: 100mm to 3000mm long and above, random, fixed and cut to length or as per customer requirements

Production: hot rolling, cold rolling, extrusion, thick plate sawing

Processing: laser cutting, punching, bending, drilling, tapping, polishing ...

Welding: 1100 filler wire is recommended for welding of the same or similar alloys.

Surface treatment: anodizing, spraying, polishing, galvanizing, nickel plating, tin plating, silver plating ... View [Detailed surface treatment process]

MASTAR 1060 aluminum bar hot-selling product types and application areas

1060 hot rolled aluminum bar

1060 hot rolled aluminum bar- 1060 hot rolled aluminum bars are produced through hot rolling process and have good mechanical properties and corrosion resistance. This product is suitable for applications requiring higher strength and thickness, such as construction, transportation and industrial equipment.

1060 cold drawn aluminum bar

1060 cold drawn aluminum bar- 1060 cold drawn aluminum bar is processed by cold drawing process, with higher dimensional accuracy and surface finish. It is suitable for precision parts and electrical components, and is widely used in the power and electronics industries due to its high hardness and strength.

1060 extruded aluminum bar

1060 extruded aluminum bar- 1060 extruded aluminum busbar is made by extrusion process, with uniform structure and excellent conductivity. It is suitable for various connection and distribution applications in the power industry due to its strong plasticity and easy forming.

1060 flat aluminum strip

1060 flat aluminum strip- 1060 flat aluminum strip is thin and flat, suitable for electrical and heat conduction components such as heat exchangers and transformers, and is also widely used in decorative applications due to its elegant appearance and good processing properties.

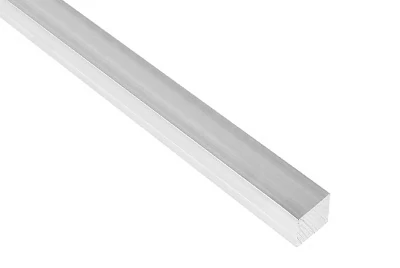

1060 aluminum square bar

1060 aluminum square bar- 1060 Square Aluminum Bars have balanced strength on all sides and are often used in support and frame applications such as light stands, lightweight structures and transportation components due to their structural stability and good corrosion resistance.

1060 conductive aluminum busbar

1060 conductive aluminum busbar- 1060 conductive aluminum busbar is widely used in power distribution and electrical connection due to its high purity and excellent conductivity. It is suitable for use under high current conditions to ensure efficient power transmission.

1060 aluminum bar chemical composition

| Element | Component % |

| Fe | 0.15 - 0.20 |

| Si | 0.10-0.15 |

| Mg | 0.01 - 0.03 |

| Mn | 0.01 - 0.03 |

| Cu | 0.01 - 0.05 |

| Zn | 0.01 - 0.03 |

| Ti | 0.020 - 0.030 |

| Al | 99.6 |

MASTAR 1060 aluminum flat bar performance reference table

| Temper | UTS (Mpa) | Elongation (%) | |||

| Minimum | Maximum | 0.5-0.8 mm | 0.81-1.30 mm | 1.30mm- above | |

| 0 | 55 | 75 | 25 | 25 | 30 |

| H14 | 90 | 120 | 5 | 5 | 6 |

MASTAR 1060 aluminum bar performance advantages

- Thermal and Electrical Conductivity: Due to its high aluminum content, 1060 flat steel is often used in applications where high electrical conductivity is required.

- Ductility: 1060 aluminum is easy to machine, form, and weld.

- Formability: Its high ductility and easy workability make it conducive to bending, cutting and forming.

- Light Weight: 1060 flat bar has a high aluminum content and is lightweight, making it suitable for applications where weight reduction is required.

- High Purity: High aluminum content provides excellent corrosion resistance and keeps it lightweight.

- Corrosion Resistance: Provides excellent resistance to weathering, chemicals and general corrosion, especially in light to moderate exposure environments.

- Surface treatment: Surface treatments such as anodizing are available, but their strength is generally not suitable for structural or load-bearing applications.

MASTAR 1060 aluminum bar surface treatment

| Surface Finish Type | Characteristics | Advantages | Typical Application |

| Anodized 1060 Aluminum Flat Bar | Adds an oxide layer, increasing corrosion resistance and surface hardness | Provides corrosion protection and allows for a variety of colors | Architectural decoration, outdoor equipment |

| Polished 1060 Aluminum Flat Bar | Smooth and reflective surface | Enhances gloss, provides a mirror-like finish | Decorative uses, furniture accessories |

| Powder Coated 1060 Aluminum Flat Bar | Adds color and protection through powder coating | Scratch-resistant, fade-resistant, suitable for outdoor applications | Industrial enclosures, building facades |

| Brushed 1060 Aluminum Flat Bar | Matte texture, with a modern feel | Reduces glare, ideal for indoor modern designs | Interior decoration, appliance casings |

| Black 1060 Aluminum Flat Bar | Anodized or coated black | Enhances visual contrast, suitable for specific design needs | Electronic device casings, frame structures |

| White 1060 Aluminum Flat Bar | Anodized or coated white | Fresh and aesthetic, enhances corrosion resistance | Architectural decoration, signage |

| 1060 Aluminum Flat Bar with Holes | Customizable holes for easy installation | Easy to install and secure, ideal for customization | Frame structures, mounting brackets |

1060 aluminum flat bar and other 1000 series alloy

MASTAR 1000 series aluminum bars are very popular in the market and have won the trust of customers with their excellent conductivity and corrosion resistance.

In addition to 1060 aluminum flat bar, we also provide other 1000 series aluminum products to meet different application needs:

- Alloy 1050 is known for its excellent corrosion resistance, formability and high reflectivity. It is often used in food industry containers, building waterproofing panels and cable sheathing, and is suitable for general sheet metal processing.

- 1070 aluminum busbar has excellent corrosion resistance and good electrical conductivity, suitable for the power and electronics industries, especially in heat exchanger and electrical conductor applications.

- 1370 aluminum busbar is a high conductivity aluminum alloy, its conductivity can reach or exceed 61.0% IACS, widely used in electrical conductors and electrical connections, especially suitable for power transmission systems.

- Although slightly stronger than 1060, 1100 alloy has similar applications and is often used to make fins, spun hollow vessels and pressurized fire extinguisher bottles, suitable for a variety of industrial needs.

- 1350 alloy is mainly used for electrical conductors. Its conductivity in -H111 state is the highest among all aluminum alloys. It is widely used in the field of electrical conductors to meet the requirements of high conductivity.

1060 aluminum bar buying guide

1.How to calculate the weight when purchasing 1060 aluminum bars

When purchasing aluminum bars on MASTAR, you can click [Calculator Service]to easily calculate the weight of 1060 aluminum bars.

2.1060 aluminum bar price

1060 aluminum bar price = (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact the sales staff to inquire about the price and processing fee per ton of various specifications of aluminum bars. The processing fee of 1060 aluminum bars of different sizes may vary greatly, and we will provide you with the best quotation.

3.MASTAR aluminum bar chamfering service

Chamfering is a common processing in the application of aluminum bars to enhance their safety, aesthetics, etc.:

- Safety: Chamfering removes sharp edges and reduces the risk of cuts during handling and use.

- Prevent fatigue: Chamfers reduce stress concentration, prevent cracks in the material, and increase the durability of the aluminum bar.

- Aesthetics: Chamfering enhances the appearance of your product, making it sleeker and more professional.

- Easy assembly: Chamfer design makes it easier to connect parts and improves assembly efficiency.

- Conductive performance: For conductive aluminum busbars, chamfering reduces the edge electric field strength, reduces the risk of arcing, improves contact quality, enhances conductivity, and enhances durability.

MASTAR can provide aluminum bar chamfering services to ensure product quality. Our processing meets strict technical and quality requirements, including accurate angles and dimensions, surface roughness, chamfer uniformity, edge treatment, material integrity and compliance with relevant standards. We are committed to providing customers with high-quality aluminum bars to ensure their safety and reliability during use.

| Chamfer radius of MASTAR aluminum and aluminum alloy extruded flat bars | ||

| Thickness | Chamfer Radius | |

| Normal Grade | High Precision Grade | |

| 2.00 ~ 10.00 | ≤2 | ≤0.6 |

| > 10.00 ~ 30.00 | ≤2 | ≤1.0 |

| > 30.00 ~ 80.00 | ≤5 | ≤1.8 |

| >80.00 ~ 120.00 | ≤8 | ≤2.0 |

| >120.00 ~180.00 | ≤8 | ≤2.5 |

| >180.00 ~240.00 | ≤10 | ≤3.5 |

4.How to choose 1060 aluminum bar supplier/stockist?

When choosing a 1060 aluminum bar supplier, it is important to consider several factors to ensure you receive high-quality material and reliable service.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, chamfering, punching, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

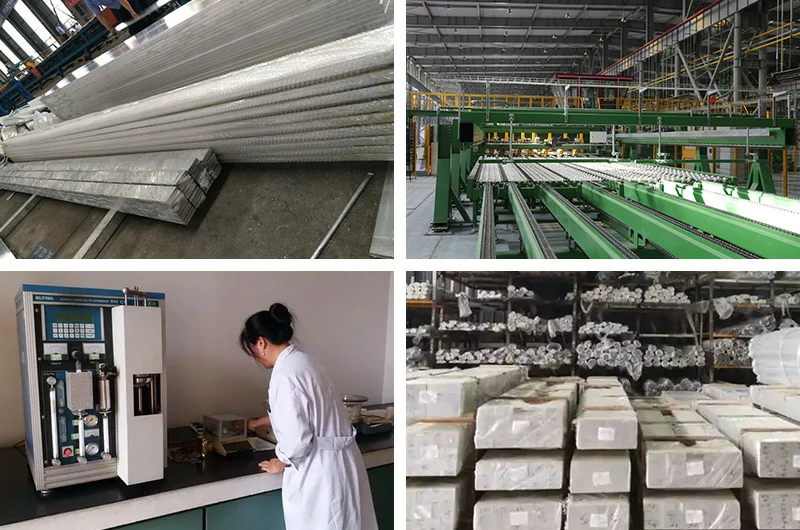

5.MASTAR 1060 aluminum bar product quality assurance

- Documents provided by us include - Certificate of Origin, Invoice and PL certified by Chamber of Commerce, PMI inspection, Hardness test, Pitting test and other tests as well as Test Certificate and other test reports as per customer's requirement.

- Full traceability of 1060 Aluminium bars and strips – the bars will be fully marked and the details can be linked to the test certificate.

MASTAR 1060 aluminum bar size reference table

Below are some of the hot-selling sizes of MASTAR's 1060 aluminum bars. If you can't find the product that suits your needs, you can click [Contact] to communicate with our sales staff about the specific product. All lengths can be cut.

| Rectangular angle aluminum flat bar/ busbar | ||||||||||

| 3mm (thickness) | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | ||||

| 4mm (thickness) | 4*10 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | |||

| 5mm (thickness) | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | ||

| 6mm (thickness) | 6*20 | 6*30 | 6*40 | 6*50 | 6*60 | 6*80 | 6*100 | 6.3*50 | 6.3*80 | ★6.3*100 |

| 7mm (thickness) | 7.6*80 | 6.3*76 | ★6.3*63 | |||||||

| 8mm (thickness) | 8*11 | 8*30 | 8*40 | 8*50 | 8*60 | ★ 8*63 | 8*80 | 8*100 | 8*120 | 8.1*74 |

| 10mm (thickness) | 10*30 | 10*40 | 10*50 | 10*60 | ★10*63 | 10*80 | 10*100 | 10*120 | 10*125 | 10*140 |

| 10*150 | 10*160 | |||||||||

| 12mm (thickness) | ★12*60 | ★12*80 | ★12*100 | 12*120 | ★ 12*125 | 12*150 | ★ 12.5*125 | |||

| 14mm (thickness) | ★14*80 | ★14*100 | Square rod | ★ 50*50 | ★ 35*55 | 19*19 | Six angle rod | ★30 | ★40 | |

| 15mm (thickness) | 15*100 | 15*120 | Round rod | ★¢10 | ★¢12 | ¢16 | ★¢28 | ★¢32 | ★¢40 | |

| 16mm (thickness) | ★16*100 | ★16*125 | Round rod | ★¢45 | ★¢46 | ★¢50 | ★¢55 | ★¢60 | ★¢65 | |

| 20mm (thickness) | ★20*80 | ★20*100 | ★¢70 | ★¢75 | ★¢80 | |||||

| Round angle aluminium flat bar/ busbar | ||||||||||

| 2mm (thickness) | R2*20 | 2mm (thickness) | R2*20 | |||||||

| 3mm (thickness) | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | 3mm (thickness) | R3*30 |

| 4mm (thickness) | R4*25 | R4*30 | R4*40 | R4*50 | R4.7*151 | 4mm (thickness) | R4*25 | |||

| 5mm (thickness) | R5*30 | R5*35 | R5*40 | R5*50 | R5*60 | R5*120 | 5mm (thickness) | R5*30 | ||

| 6mm (thickness) | R6*50 | R6*60 | R6*80 | ★R6.3*63 | R6*100 | R6*120 | R6*140 | R6*160 | 6mm (thickness) | R6*50 |

| 8mm (thickness) | R8*40 | R8*50 | R8*60 | ★R8*63 | R8*80 | R8*100 | 8mm (thickness) | R8*40 | ||

| 10mm (thickness) | R10*50 | R10*60 | R10*80 | R10*100 | ★R10*120 | R10*125 | R10*170 | R10.4*25 | 10mm (thickness) | R10*50 |

| 12.5mm (thickness) | ★R12.5*80 | ★R12.5*125 | ★R16*120 | 12.5mm (thickness) | ★R12.5*80 | |||||