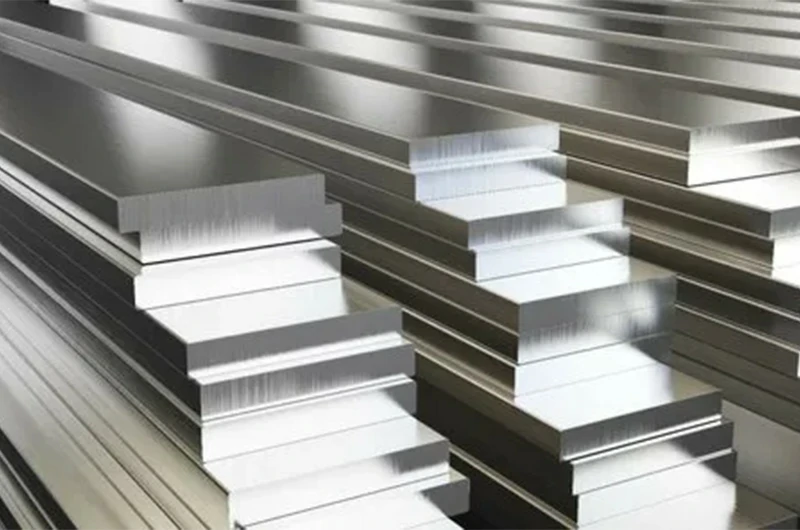

1370 aluminum busbar is an aluminum alloy material with good mechanical strength and corrosion resistance, which is widely used in power, machinery and construction. Although its conductivity is not as good as 1350 and 1070 aluminum busbars, 1370 aluminum busbar can still meet most electrical needs.

It has low cost and good processability, is easy to weld and form, and is suitable for a variety of structural and connection applications. With its excellent comprehensive performance, 1370 aluminum bar has become an important connection element in industrial and power systems.

MASTAR 1370 aluminum bar product introduction

Size: 5 mm to 500 mm; click to view detailed [Size Table]

Length: 100 mm to 3000 mm long and above, up to 6 meters long; random, fixed and cut to length or as per customer requirements

Production: hot rolling, cold rolling, extrusion, thick plate sawing

Processing: laser cutting, punching, bending, drilling, tapping, polishing ...

Welding: 1100 filler wire is recommended for welding of the same or similar alloys.

MASTAR 1370 aluminum bar hot-selling product types and application areas

1370 extruded aluminum bar

1370 extruded aluminum bar- This aluminum busbar is manufactured through an extrusion process and has excellent electrical conductivity and mechanical properties. It is widely used in electrical equipment and building structures.

1370 transformer flat bar

1370 transformer flat bar- This aluminum busbar is manufactured through an extrusion process and has excellent electrical conductivity and mechanical properties. It is widely used in electrical equipment and building structures.

1370 aluminum alloy busbar

1370 aluminum alloy busbar- Although the conductivity of 1370 aluminum alloy busbar is not as good as 1050, 1060 and 1070, it is suitable for use in power systems due to its excellent strength and corrosion resistance. Its cost-effectiveness and good weldability make installation and maintenance convenient.

1370 square aluminum bar

1370 square aluminum bar- It not only has good strength and corrosion resistance, but also has the characteristics of light weight and easy processing. In particular, its square cross-section makes its structure stable and easy to connect and assemble, making it widely used in many industries.

1370 aluminum bar chemical composition

| Element | Component % |

| Si | <0,1 |

| Fe | <0,25 |

| Cu | <0,02 |

| Mn | <0,01 |

| Mg | <0,02 |

| Cr | <0,01 |

| Zn | <0,04 |

| V | Sum<0,02 |

| Ti | |

| B | <0,02 |

| Other | <0,02 |

| Other total | <0,1 |

| Al | ≥ 99,7 |

MASTAR 1370 aluminum bar mechanical properties reference table

| MECHANICAL PROPERTIES @ 20°C | |||

| Temper | Tensile strength (MPa) | Elongation 200mm (%) | |

| min. | max. | ||

| H15 | 125 | 140 | 5-15 |

| H14 | 115 | 130 | 5-15 |

| H13 | 105 | 120 | 7-20 |

| H12 | 95 | 110 | 1 0-30 |

| H11 | 80 | 95 | 15 - 35 |

| O | 60 | 80 | 30 - 50 |

MASTAR 1370 aluminum row performance advantages

- Excellent conductivity: Although not as good as high-purity aluminum, the conductivity of 1370 aluminum busbar is stable in practical applications and is suitable for a variety of electrical needs.

- Higher strength: Compared with other aluminum alloys, 1370 aluminum bars provide better mechanical strength and can withstand greater loads and pressures.

- Corrosion resistance: 1370 aluminum alloy has good corrosion resistance, suitable for wet or harsh environment, and prolongs service life.

- Easy to process: MASTAR 1370 aluminum bars can be easily cut, welded and formed, which improves the flexibility of processing and installation.

- Cost-effectiveness: Compared with high-purity aluminum, MASTAR 1370 aluminum ribs have lower material costs while maintaining performance, making them suitable for large-scale applications.

- Versatility: Applicable to multiple industries such as electricity, machinery, and construction, showing good adaptability and multi-purpose characteristics.

1370 aluminum bar vs 1350 aluminum bar vs 1070 aluminum bar

Conductivity comparison:

- 1350 aluminum busbar: Optimal electrical conductivity, suitable for applications with extremely high electrical conductivity requirements, such as power transmission.

- 1070 aluminum busbar: Its conductivity is second only to 1350 and is suitable for general electrical applications.

- 1370 Aluminum Busbar: Relatively low conductivity, but still sufficient for most power needs.

Strength comparison:

- 1370 aluminum bar: provides high mechanical strength and is suitable for applications with heavy loads.

- 1350 aluminum bar and 1070 aluminum bar: lower strength, mainly suitable for electrical connections.

Corrosion resistance comparison:

All three aluminum busbars have good corrosion resistance, but 1370 aluminum busbar may perform better in certain environments due to its alloy composition.

Cost Comparison:

- 1350 aluminum bar: Relatively high cost, suitable for specific applications with high performance requirements.

- 1070 aluminum bar and 1370 aluminum bar: usually lower cost and suitable for large-scale applications.

Processability comparison:

All three have good machinability, but 1370 aluminum bar may have more advantages in welding and forming due to its alloy properties.

Comparison of application areas:

- 1350 aluminum busbar: widely used in high current transmission and power equipment.

- 1070 aluminum busbar: suitable for general electrical and electronic products.

- 1370 aluminum bar: suitable for various fields such as electricity, machinery and construction, especially in occasions where strength and corrosion resistance are required.

| Performance/Features | 1370 aluminum bar | 1350 aluminum bar | 1070 aluminum bar |

| Electrical conductivity | Low, but meets general power needs | Optimal for high current delivery | Second best, suitable for general electrical applications |

| strength | Higher, suitable for carrying loads | Lower | Lower |

| Corrosion resistance | good | good | good |

| cost | Lower | Higher | Lower |

| Processability | Good for welding and forming | good | good |

| Application Areas | Electricity, machinery, construction and other fields | High current transmission and power equipment | General electrical and electronic products |

1370 aluminum bar buying guide

1.How to calculate the weight when purchasing 1370 aluminum bars

When purchasing aluminum bars on MASTAR, you can click [Calculator Service]to easily calculate the weight of 1370 aluminum bars.

2.1370 aluminum bar price

1370 aluminum bar price = (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact the sales staff to inquire about the price and processing fee per ton of various specifications of aluminum bars. The processing fee of 1370 aluminum bars of different sizes may vary greatly. We will provide you with the best quotation.

3.MASTAR aluminum bar chamfering service

Chamfering is a common processing in the application of aluminum bars to enhance their safety, aesthetics, etc.:

- Safety : Chamfering removes sharp edges and reduces the risk of cuts during handling and use.

- Prevent fatigue : Chamfers reduce stress concentration, prevent cracks in the material, and increase the durability of the aluminum bar.

- Aesthetics : Chamfering enhances the appearance of your product, making it more sleek and professional.

- Easy assembly : Chamfer design makes it easier to connect parts and improves assembly efficiency.

- Conductive performance : For conductive aluminum busbars, chamfering reduces the edge electric field strength, reduces the risk of arcing, improves contact quality, enhances conductivity, and enhances durability.

MASTAR can provide aluminum bar chamfering services to ensure product quality. Our processing meets strict technical and quality requirements, including accurate angles and dimensions, surface roughness, chamfer uniformity, edge treatment, material integrity and compliance with relevant standards. We are committed to providing customers with high-quality aluminum bars to ensure their safety and reliability during use.

| Chamfer radius of MASTAR aluminum and aluminum alloy extruded flat bars | ||

| Thickness | Chamfer Radius | |

| Normal Grade | High Precision Grade | |

| 2.00 ~ 10.00 | ≤2 | ≤0.6 |

| > 10.00 ~ 30.00 | ≤2 | ≤1.0 |

| > 30.00 ~ 80.00 | ≤5 | ≤1.8 |

| >80.00 ~ 120.00 | ≤8 | ≤2.0 |

| >120.00 ~180.00 | ≤8 | ≤2.5 |

| >180.00 ~240.00 | ≤10 | ≤3.5 |

4.How to choose 1370 aluminum bar supplier /stockist?

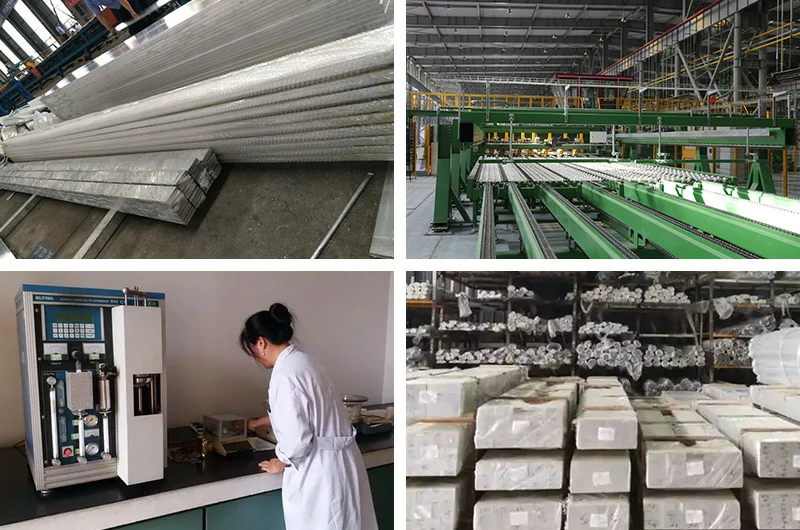

When choosing a 1370 aluminum bar supplier, it is important to consider several factors to ensure you receive high-quality material and reliable service.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, chamfering, punching, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

5.MASTAR 1370 aluminum bar product quality assurance

- Documents provided by us include - Certificate of Origin, Invoice and PL certified by Chamber of Commerce, PMI inspection, Hardness test, Pitting test and other tests as well as Test Certificate and other test reports as per customer's requirement.

- Full traceability of 1370 Aluminium bars and strips – the bars will be fully marked and the details can be linked to the test certificate.

MASTAR 1370 aluminum flat bar size reference table

Below are some of the hot-selling sizes of MASTAR's 1370 aluminum bars. If you can't find the product that suits your needs, you can click Quick Quoteto communicate with our sales staff about the specific product. All lengths can be cut.

| Rectangular angle aluminum flat bar/ busbar | ||||||||||

| 3mm (thickness) | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | ||||

| 4mm (thickness) | 4*10 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | |||

| 5mm (thickness) | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | ||

| 6mm (thickness) | 6*20 | 6*30 | 6*40 | 6*50 | 6*60 | 6*80 | 6*100 | 6.3*50 | 6.3*80 | ★6.3*100 |

| 7mm (thickness) | 7.6*80 | 6.3*76 | ★6.3*63 | |||||||

| 8mm (thickness) | 8*11 | 8*30 | 8*40 | 8*50 | 8*60 | ★ 8*63 | 8*80 | 8*100 | 8*120 | 8.1*74 |

| 10mm (thickness) | 10*30 | 10*40 | 10*50 | 10*60 | ★10*63 | 10*80 | 10*100 | 10*120 | 10*125 | 10*140 |

| 10*150 | 10*160 | |||||||||

| 12mm (thickness) | ★12*60 | ★12*80 | ★12*100 | 12*120 | ★ 12*125 | 12*150 | ★ 12.5*125 | |||

| 14mm (thickness) | ★14*80 | ★14*100 | Square rod | ★ 50*50 | ★ 35*55 | 19*19 | Six angle rod | ★30 | ★40 | |

| 15mm (thickness) | 15*100 | 15*120 | Round rod | ★¢10 | ★¢12 | ¢16 | ★¢28 | ★¢32 | ★¢40 | |

| 16mm (thickness) | ★16*100 | ★16*125 | Round rod | ★¢45 | ★¢46 | ★¢50 | ★¢55 | ★¢60 | ★¢65 | |

| 20mm (thickness) | ★20*80 | ★20*100 | ★¢70 | ★¢75 | ★¢80 | |||||

| Round angle aluminium flat bar/ busbar | ||||||||||

| 2mm (thickness) | R2*20 | 2mm (thickness) | R2*20 | |||||||

| 3mm (thickness) | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | 3mm (thickness) | R3*30 |

| 4mm (thickness) | R4*25 | R4*30 | R4*40 | R4*50 | R4.7*151 | 4mm (thickness) | R4*25 | |||

| 5mm (thickness) | R5*30 | R5*35 | R5*40 | R5*50 | R5*60 | R5*120 | 5mm (thickness) | R5*30 | ||

| 6mm (thickness) | R6*50 | R6*60 | R6*80 | ★R6.3*63 | R6*100 | R6*120 | R6*140 | R6*160 | 6mm (thickness) | R6*50 |

| 8mm (thickness) | R8*40 | R8*50 | R8*60 | ★R8*63 | R8*80 | R8*100 | 8mm (thickness) | R8*40 | ||

| 10mm (thickness) | R10*50 | R10*60 | R10*80 | R10*100 | ★R10*120 | R10*125 | R10*170 | R10.4*25 | 10mm (thickness) | R10*50 |

| 12.5mm (thickness) | ★R12.5*80 | ★R12.5*125 | ★R16*120 | 12.5mm (thickness) | ★R12.5*80 | |||||