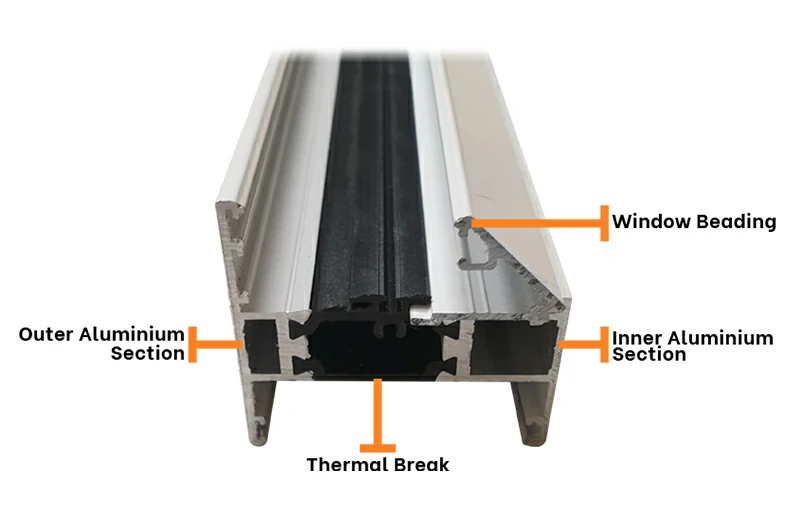

Thermal insulation aluminum profiles, also known as thermal break aluminum or thermal break aluminum profiles, are composite materials consisting primarily of aluminum profiles filled with thermal insulation material. They are designed to provide thermal insulation and are commonly used in the construction industry for applications such as aluminum alloy doors and windows, and thermal insulation roof systems.

Common thermal insulation aluminum profile

- Thermal insulation roofing profiles

- Thermal insulation door profiles

- Thermal insulation curtain wall aluminum profiles

Thermal insulation aluminum profile alloy selection

| Alloy Series | Common alloy grades | Characteristics |

| 3000 | 3003, 3004 | Good corrosion resistance and weldability |

| 5000 | 5052, 5083 | High strength and excellent corrosion resistance |

| 6000 | 6061, 6063 | Excellent mechanical properties and strength |

Advantages of thermal insulation aluminum profiles

- Excellent thermal insulation: Thermal insulation aluminum profiles use PA66 nylon strips with low thermal conductivity, effectively preventing heat loss.

- Soundproofing: Filled with thermal insulation materials, the joints are tightly sealed, resulting in sound insulation of less than 30 decibels according to test results.

- Impact resistance: The outer layer is made of aluminum alloy, providing better impact resistance compared to plastic steel window profiles.

- Good air tightness: Thermal break aluminum windows are installed with multiple sealing strips, ensuring good air tightness.

- Excellent water tightness: Doors and windows are designed with rainproof structures, preventing water infiltration.

- Good fire resistance: Aluminum alloy is a non-combustible material, contributing to good fire resistance.

- Low maintenance: Thermal break aluminum window profiles are resistant to acid and alkali corrosion, do not yellow or fade, and require minimal maintenance.

Production process of thermal insulation aluminum profiles

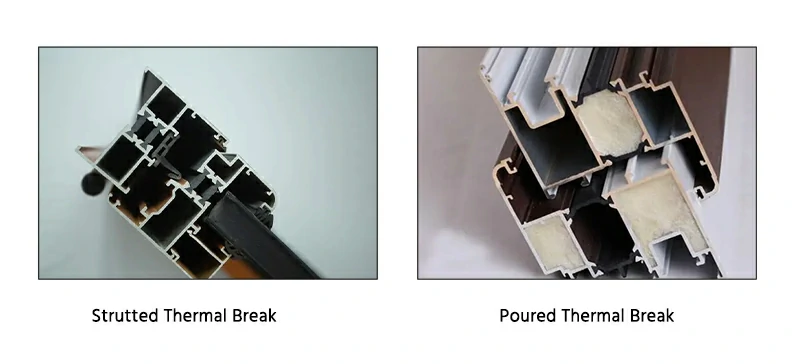

Thermal Strut

The method involves using reinforced fiberglass thermal insulation strips inserted into the grooves at the center of two aluminum profiles. These are then connected into one integrated thermal insulation profile through specialized rolling machines.

Pour and debridge

The aluminum profiles with surface treatment are moved in a straight line using a conveyor system. When the thermal insulation grooves of the aluminum profiles pass under the pouring head of the pouring machine, liquid thermal insulation material flows into the grooves. After a certain period of solidification, the excess material is then removed through a cutting process.

Difference

| Comparison item | Thermal Strut Aluminum Profiles | Pour and Debridge Aluminum Profiles |

| Insulation materials | Polyamide 66 + Ultrafine Glass Fiber | Polyurethane Thermal Insulation Adhesive |

| Thermal insulation | Good | Excellent |

| Substrate strength | Low (due to compression, high strength is prone to breakage) | High |

| Cross-sectional area | Large | Small |

| Material yield per unit weight | Low | High |

| Plasticity | Limited shape (large deformation may cause thermal insulation strips to detach) | Can be made into various shaped doors and windows |

| Price | High | Low |

Why choose Mastar-Metal as your aluminum supplier?

- Procurement from source, lowest price guaranteed

- A wide range of mold types, providing customized services to save costs

- Provide various quality inspection reports

- Fast and on time delivery

- Detailed shipping, tax information