Aluminum is widely used in the passenger car and commercial vehicle industries due to its lightweight and high-strength properties. Aluminum not only significantly improves vehicle performance and fuel economy; it also improves overall vehicle performance without compromising safety.

Comprehensive application of automotive aluminum: in-depth analysis from body structure to interior and exterior decoration

MASTAR designs and manufactures aluminum products for all vehicles, covering all vehicle systems such as passenger cars, commercial vehicles, racing cars, new energy vehicles, etc.

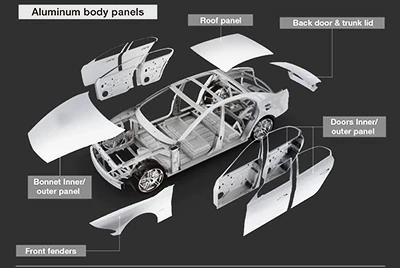

Aluminum plate for automobile body

- Automobile shells typically use 5000 and 6000 series aluminum alloy sheets for doors, hoods, roofs, and tailgates, offering excellent deep drawing, hot forming, dent resistance, baking hardening, gloss hardening, and lightweight benefits.

- Surface treatment: anodizing

| Automobile body sheet alloy and part comparison table | ||

| Location | Alloys and products | Material properties |

| Inner and outer coverings (shell plates) | 2008, 2010, 2036 3004(External Covering) 5052, 5182(inner hull), 5754(inner hull) 6022(Inner and outer shell), 6016, 6A16, 6014 Aluminum alloy honeycomb panel | These alloys combine excellent formability, strength and corrosion resistance for automotive interior and exterior panels. They ensure that body parts maintain structural strength while providing durability and good appearance, adapting to a variety of complex shapes and environmental conditions. |

| Door inner panel, skylight panel, fence inner panel | 6010, 6009, 6016 Aluminum alloy honeycomb panel | Good stamping and forming properties, suitable for parts with complex shapes. |

| Front gate | 6010 Aluminum alloy honeycomb panel | Good strength and flatness, suitable for key parts such as front gate. |

| Siding | 6010, 6111 | High strength, good formability, excellent corrosion resistance and weldability, suitable for wall panels subject to greater stress. |

| Wings (front wing, sliding wing, outer wing) | 6010, 6016 | Suitable for complex shaped wings, with good formability and strength. |

| fender | 5182, 5754 | Excellent corrosion resistance and formability, suitable for fenders exposed to external environment for a long time. |

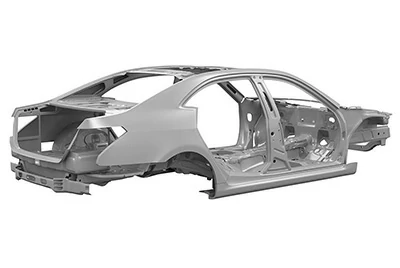

Aluminum profiles for use in body in white (BIW)

- Vehicles require a strong body structure to support weight and pressure, and to firmly connect various components. Aluminum, with its high tensile strength and lightweight characteristics, is an ideal and sustainable choice. MASTAR offers a variety of aluminum materials for automotive body-in-white (BIW), from simple extruded profiles to complex sections, as well as complete aluminum chassis, with products, systems, expertise and solutions.

| Automobile body structural alloy and part comparison table | ||

| Location | Alloy | Material properties |

| Automobile profiles/body frames | 6082, 6061 | High strength, good processability and weldability, suitable for vehicle body frames subject to heavy loads. |

| Roof rails | 6063, 6005 | Good corrosion resistance and formability, suitable for roof rails with complex cross-sections. |

| Body parts/structural reinforcements | 6082, 7075 | 6082: High strength and fatigue resistance; 7075: Extremely high strength and hardness, suitable for high stress areas. |

| Automobile beam | 6061, 6082 | High strength and good corrosion resistance, suitable for structural parts subject to pressure and stress. |

| Anti-collision beam/anti-collision frame/anti-collision frame energy absorption box | 6063, 6061, 6082, 7003 | 7003: Excellent strength and impact resistance; 6061,6082: High strength and fatigue resistance, suitable for energy absorption and protective structures. |

| bumper | 6061, 7075, 7003, 7046 | 6061: high strength and good durability; 7075: extremely high hardness and impact resistance, suitable for safety protection purposes. |

Aluminum sheets and profiles for automotive chassis systems

- Chassis components such as suspension systems, subframes, control arms, etc. usually use aluminum profiles and aluminum castings. The alloy types are usually 6061, 6082, etc., which have high strength and fatigue resistance.

| Automobile chassis alloy and part comparison table | |||

| Location | Alloy | Material properties | |

| Subframe | 6061, 6082, 7003 | High strength, fatigue resistance and corrosion resistance, suitable for carrying and supporting the weight of the vehicle body. | |

| Chassis frame and power tray | 6009, 6061, 7021 | Strong and durable, with a balance of strength and lightness, suitable for bearing the weight of the vehicle body and power system. | |

| Suspension | Suspension Link | 6082, 5154 | It has excellent mechanical properties, fatigue resistance and durability and is suitable for highly loaded suspension components. |

| Shock absorber/shock mount | 5052, 6061, 6009, 7003, 7021, 7029 | ||

| Control Arm | 6061, 6082, 7075 | ||

| Steering system | Front and rear steering knuckle | 6082, 7075 | High strength and durability ensure the stability and precision of the steering system. |

| Steering linkage | 6061, 6082, 7075 | ||

| Drive system | Transmission/Differential | 6061, 6082 | Excellent processing performance and fatigue resistance, suitable for drive and transmission components subject to rotation and torque. |

| Drive shaft | 6061 | ||

| transmission shaft | 6063, 6463, 6262, 6151 | ||

| Braking system | Brake box parts | 6082, 6262 | High strength, corrosion resistance and wear resistance ensure the long-term stability and reliability of the braking system. |

| Vacuum booster pump | 5754, 5182 | ||

| Brake series products | 6061, 6082, 7075 | ||

| ABS valve | 6061, 6082, 7075 | ||

| Wheel hub | 6061, 6082, 6063, 5454, 6010, 6151 | High strength and impact resistance, suitable for wheel hub parts that bear vehicle loads and road impacts. | |

Aluminum sheet and aluminum profile for automobile power system

- Using aluminum in powertrain and engine systems can improve efficiency, reduce weight and lower vehicle production costs. MASTAR's aluminum engine parts have excellent machinability and mechanical properties.

| Automobile power system alloy and part comparison table | |||

| Location | Alloy | Material properties | |

| Engine systems and components | Engine cover inner and outer panels | 6010, 6016, 6111 | It has good formability and corrosion resistance, is lightweight and provides appropriate strength. |

| Engine auxiliary bracket and engine mount | 5454, 6061, 5083, 6082 | High strength and fatigue resistance, suitable for supporting and fixing engines under high stress conditions. | |

| Engine Parts | 6063, 6082 | Excellent processing performance and corrosion resistance, suitable for complex shape engine components. | |

| piston | 4032, 2618, 6262 | High strength, high temperature resistance and wear resistance ensure stability and durability when the engine runs efficiently. | |

| Turbocharger housing | 2618 | Extremely high heat resistance and strength, able to maintain stable performance under high temperature and high pressure conditions. | |

| Motor | Generator housing | 6061 | Good corrosion resistance and strength, suitable for the protective shell of the generator, ensuring stability during long-term use. |

| Generator bracket | 6061 | High strength and good processability can effectively support and fix the generator to ensure its normal operation. | |

Aluminum foil and profiles for automotive interiors decorative

- Aluminum trim and interior reduce weight and support sustainability, promoting a green automotive future. MASTAR offers high-spec aluminum extrusions for trim parts like decorative strips, door handles, grooves, and instrument panels.Further processing services: matte or shiny, embossed or embossed

| Comparison table of aluminum alloys and parts for automotive interior | |

| Parts used | Alloy |

| Loading floor | 2036, 5182, 5754, 6009 |

| Various brackets | 6151 |

| Seat frame | 2036, 6010, 6009 |

| Seat Track | 7003, 7129, 6010 |

| Door and window frames | 6063, 6463 |

| Sealing strip | 5754-H24, 3105-H28 |

| Car B-pillar decoration | 3005-H22, 5754-O |

| Body sheet metal | 6009, 6111, 6016 |

| Decoration/Inlays/Nameplates | 1100, 3002, 5005, 5252, 5457, 5657 |

| Audio | 5052-H32 |

| Air cleaner tray and hood | 5182, 5754 |

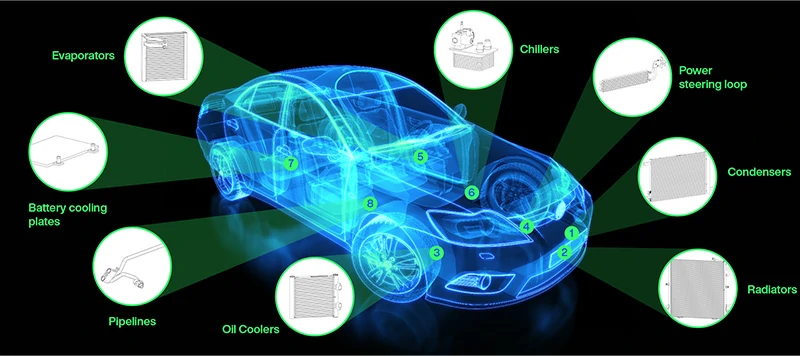

Aluminum alloy brazing materials for automotive heat exchange systems

In modern cars, brazed aluminum sheets, strips, foils, tubes and other materials are widely used in heat exchange systems such as engine radiators, oil radiators, intercoolers, air conditioning condensers and evaporators. Aluminum is an ideal choice for automotive thermal management due to its strength, corrosion resistance, weight reduction, excellent thermal conductivity and sustainability, effectively managing vehicle temperature and improving environmental credentials.

MASTAR focuses on providing high-quality aluminum products to customers around the world, covering various specifications of plates, strips, foils, composite strips (foils), extruded round tubes, flat tubes, porous flat tubes and welded tubes. We are committed to helping customers manufacture automotive parts that can maintain optimal temperatures under any conditions and promote the future development of the automotive industry.

| Reference table of various aluminum heat exchanger and intercooler structures and main materials used | ||

| Structural form | Heat sink | Cooling water pipe |

| Tube and belt vacuum brazing | 1100, 3003, 3005, 6063, 5005, 6951 | Double-sided composite tape is welded into a flat tube by high-frequency seam welding 4045/3003/7072/4045/3005/7072 4A17/3003/7A01, 4A17/3005/7A01 |

| Gas shielded brazing of pipes | 3003, 3003+Zn, 3203+Zn, 7072 | Double-sided composite tape is welded into a flat tube by high-frequency seam welding 4043+Zn/3003/7072, 4045+Zn/3003/7072, 4043+Zn/3003/7 A01, 4045+Zn/3003/7 A01 |

| The pipe segment is a structure | 1050, 1100, 1145, 3A21, 3003, 7072, 7A01, 8006, 8007 | Extruded or high frequency seam welded round tube 1050, 1100, 3003, 3A21, 1050 |

| Corrugated welding | 1100, 3003 | Extruded flat tube or porous flat tube 1050, 3003, 3A21 |

| Plate fin welding | 1100, 3003 | Stamped plate fin 3003, 3A21 |

- Heat Exchanger

6591, 6051, 6061

3003 (Brazed Heat Exchanger Tubes)

- Heat sink

3003 (Radiator)

3005 (Brazing Radiator Tubes)

7072 (Radiator fin)

5182-O (Engine Radiator)

- Heater

3003 (heater fins and inner and outer tubes)

3005 (heater and edge support)

- Intercooler

3003, 4045, 6061

- Oil Cooler

3003

- Condenser/(Extrusion) Condenser Tube

1200, 7072

- Evaporator

3005

- Heat transfer fins

1200

- Air conditioning pipe

3003

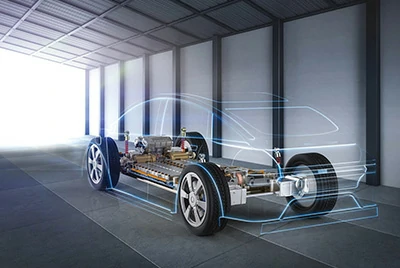

Aluminum alloy breakthrough in new energy vehicles: innovative applications from battery trays to vehicle frames

- Aluminum plays an important role in the lightweighting of electric and hybrid vehicles. MASTAR aluminum electric vehicle components include battery packs and housing frame solutions for all electric vehicles. Other products include aluminum battery cables, radiator systems, motor housings, cabin heaters and structural body parts.

- Battery cooling system: Battery thermal management requires an efficient cooling system. Aluminum brazing composite materials are widely used in battery liquid cooling plates to improve cooling effects and ensure battery safety and performance.

- Lightweight design: In order to extend the driving range, electric vehicles rely more on lightweight materials. Aluminum is an ideal choice for body structure, chassis and other key components due to its lightness and strength.

- Electric motors and electronic control systems: Aluminum's good electrical conductivity and heat dissipation properties make it the preferred material for components such as motor housings and electronic control module heat sinks, helping to improve system stability and efficiency.

- Thermal management system: New energy vehicles require a more complex thermal management system. Aluminum materials are widely used in radiators, condensers, air-conditioning systems and other components to ensure temperature control of the vehicle under various operating conditions.

| Comparison table of aluminum alloys and parts for electric vehicles | |||

| Application area | Application and Gold | Product form | |

| Power battery shell | 1050,3003,3005 | Aluminum Coil | |

| Power battery cover | 3003,5182 | Aluminum Plate | |

| Power battery side panel | 5083 | Aluminum Plate | |

| Battery Tray | 6063,6016,6061,6082,5083 | Aluminum sheet, aluminum alloy extrusion | |

| Power battery water cooling plate | 3003 3003/43443 | Brazed composite plate | |

| Aluminum foil for power battery soft connection | 1060 | Aluminum foil | |

| Electric vehicle line | Electric vehicle internal wiring | 8000 Series | Aluminum wire |

| Aluminum wire and cable for charging infrastructure | ACSR, AAAC | Aluminum alloy stranded wire, cable | |

The Green Case——How Aluminum Reduces Vehicle Weight and Carbon Emissions

- Aluminum is strong, efficient, safe, recyclable, and abundant. For every 0.45 kg (1 pound) of aluminum used in a car instead of steel, the vehicle loses 0.45 kg of weight. This metal keeps vehicles on the road safer and more efficient. Aluminum has become increasingly popular in the automotive industry over the years. It is used to produce engines, transmissions, suspensions, wheels, brake parts, frames, magnets for tachometers and speedometers, wiring, air conditioning components, and even body parts.

- Here is a formula that makes it easier to understand the importance of reducing the weight of a car. Assume that a car has traveled 200,000 kilometers, which is about 125,000 miles. Assume that the secondary weight is reduced by 20%. On average, 1 kilogram of weight is saved for every kilogram of aluminum, because steel weighs twice as much as aluminum.

- Every kilogram of aluminum used in a car saves 19 kilograms of CO2 over the car's lifetime. If we also take into account the production and distribution of fuel (wheel-to-wheel), we can say that a 100 kilogram reduction in vehicle weight means 10 grams of CO2 per kilometer, or 2,000 kilograms over the car's lifetime.

Mastar——Your professional automotive aluminum supplier and technical service expert

- Comprehensive aluminum product supply: We provide a full range of aluminum products from aluminum alloy sheets, strips, foils to aluminum tubes, profiles, brazing materials, etc. to meet the needs of different components in automobile manufacturing.

- Technical support and customization services: Our professional team provides technical support and material customization services for the automotive industry to ensure the best application effect of aluminum and help customers improve product performance.

- High quality and strict quality control: We adhere to the highest quality standards. All aluminum products undergo rigorous testing and certification to ensure that we provide customers with reliable aluminum that meets the requirements of the automotive industry.

- Fast delivery and global supply chain: With a complete supply chain network, we can respond quickly to customer needs and provide efficient logistics services around the world to ensure on-time delivery of aluminum.

- Sustainability and environmental commitment: We are committed to providing aluminum materials with sustainable and environmental advantages to help customers reduce carbon emissions and promote green automobile manufacturing.

More recommendations——MASTAR aluminum for commercial vehicles

- Aluminum for trailers

- Aluminum for tank trucks

- Aluminum Truck