Aluminum extrusion profiles are widely used in the construction sector, becoming an indispensable key material for the industry. Their unique attributes include being lightweight, having diverse material properties, and offering a wide range of surface treatments and processing options.

As the cornerstone of lightweight building structures, aluminum profiles provide architects and designers with unique design flexibility and manufacturing convenience. Compared to other materials, the advantages of aluminum profiles lie in their sustainability and eco-friendliness, making them one of the preferred choices in the construction field.

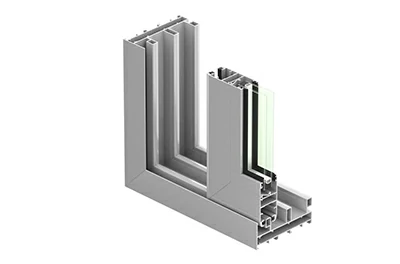

Architectural window and door profiles

Aluminium window profiles

Aluminum windows are one of the most widely used products in the field of architectural aluminum extrusion. They are typically made from 6063-T5 alloy, which offers excellent corrosion resistance and ease of assembly.

- Aluminium window profiles

- Aluminum frame profiles for windows

- Aluminum window glass extruded profiles

- Aluminum window insulation profiles

Aluminium door profiles

Aluminum Doors mainly refer to the door frame systems, which can generally be divided into casement doors, sliding doors, double doors, etc. The commonly used alloy is 6063 in T5 and T6 tempers.

- Aluminium door profiles

- Aluminum frame profiles for doors

- Aluminum frame profiles for doors

- Aluminum frame profiles for doors

Aluminium glass profile

Extruded Aluminum Glass Profiles are primarily used for door and window assembly as well as furniture fixing. These specially designed profiles are made from 6060 alloy, offering high corrosion resistance.

- Aluminium glass profile

- Aluminum spacer profile

- Aluminum Pressure Plate Bar

- Aluminum glazing bead

Aluminum window track

Aluminum sliding tracks are key components in door and window systems. They support and guide the sliding motion of doors and windows, ensuring smooth opening and closing. They are widely used in sliding doors and windows, lift-and-slide windows, and folding doors. The commonly used alloys are 6061 and 6063.

- Aluminum window track

- Profile for aluminum two track window

- Profile for aluminum three track window

- Profile for aluminum four track window

Aluminium door hardware profiles

Door and window hardware profiles are profiles used for various accessories and components in door and window systems, including door locks, handles, hinges, weatherstrips, etc. Their role is to support, operate, fix, and enhance the aesthetics of door and window structures.

Window and door hardware profiles

Window and door hardware profiles- Aluminum handle

- Aluminum hinge

- Aluminum corner code

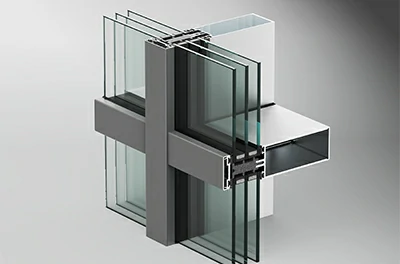

Curtain wall aluminium section

Aluminum curtain wall profile

Building facade profiles refer to various aluminum profiles used in aluminum curtain wall systems, including columns, beams, pressure bars, and clamping strips. They are typically made from 6000 series alloys such as 6060, 6005, 6061, 6063, 6082, among others. These profiles play a crucial role in providing structural support and aesthetic enhancement to curtain wall systems in buildings.

- Aluminum curtain wall profile

- Aluminium Vertical Mullion

- Aluminum Transom

- Aluminum Fasteners

Aluminium facade support structures

Aluminum facade support structures are lightweight, corrosion-resistant systems used in building exteriors. They are capable of supporting architectural glass curtain walls or decorative panels. Commonly used alloys include 6061, 6063, and 6082 due to their favorable properties such as ease of processing and corrosion resistance.

Aluminium facade support structures

Aluminium facade support structures- Aluminum Top hat profile

- Aluminum Wall bracket

- Aluminum L-bracket (support profile)

- Aluminum Edge Profiles

Aluminium trim profiles

Aluminium fencing & handrail

Aluminium fencing and handrails typically refer to various architectural applications such as stair handrails and public area fences and handrails. They are commonly made from alloys such as 6005, 6061, and 6063. These profiles can be customized with surface treatments including anodizing, powder coating, and electrophoretic coating to enhance their durability and aesthetics.

- Aluminium fencing & handrail

- Aluminum Fencing Accessories

- Aluminum Handrail Decorative

- Aluminum Connectors

Aluminium stair nosing

Aluminium stair nosing is a versatile and durable stair protection solution suitable for various indoor and outdoor environments. Its high-quality flat safety surface can conceal imperfections and is compatible with various flooring types such as wood, tiles, carpets, and LVT. Lightweight and easy to handle, it is easy to replace if damaged, making it an efficient and reliable stair protection solution.

Aluminum awning extrusions

Aluminum Awning Extrusions are specifically designed for outdoor sunshade and protection structures. They are widely used in residential, commercial, and public buildings to provide shading, rain protection, and decorative beautification. Commonly used alloys include 6061-T6, 6063-T5, and 6082-T6.

- Aluminum awning extrusions

- Aluminum profiles for awning tracks

- Aluminum profiles for awning mounts

- Aluminum Awning Hardware

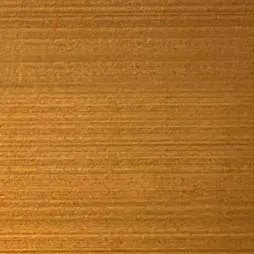

Aluminum profile ceiling

Aluminum metal ceilings are extensively used in modern commercial buildings due to their aesthetic appeal, lightweight, and ease of installation. They are commonly made from alloys such as 3003 and 6063, and can undergo surface treatments like oxidation, electrophoretic coating, and wood grain transfer printing.

Aluminum profile ceiling

Aluminum profile ceiling- Aluminum Linear Metal Ceiling

- Aluminum Grid Ceiling

- Curved Aluminum Ceiling

- Aluminum Mesh Ceiling

Aluminum grilles profiles

Aluminum grilles are aluminum alloy structures used for ventilation, light control, decoration, and safety protection. They are widely applied in architectural facades, ceilings, ventilation systems, fence screens, stairways, and corridors where ventilation or decoration is required. Commonly used alloys include 3003, 6061, and 6063.

Aluminum grilles profiles

Aluminum grilles profiles- Aluminium Grilles for Facades

- Aluminum ventilation grill

- Aluminium Window Grilles

- Aluminium Parking Garage Grille

Aluminium curtain track profiles

Aluminum curtain rod/rail profiles are aluminum profiles used for hanging curtains and providing motion tracks. They are designed to be compact, lightweight, and sturdy. Commonly used alloys include 6061 and 6063. Various surface finishes such as oxidation and electrostatic spraying are available options.

Aluminium curtain track profiles

Aluminium curtain track profiles- Aluminum Straight Track Profiles

- Aluminum Curved Track Profiles

- Aluminum Double Track Profiles

Extruded aluminum trim

Aluminum decorative trim is metal trim used for wall surfaces, floor edges, tile corners, and transition areas, offering protection, beautification, and transitional effects. It boasts high durability and modern aesthetics. Commonly made from alloy 6063-T5, it offers a variety of surface treatments including anodizing, electrophoretic coating, and brushing.

- Extruded aluminum trim

- Aluminum Wall Trim Profiles

- Aluminum Skirting Boards

- Aluminum Floor Trim Profiles

- Aluminum Transition Trim Profiles

Aluminum louvers profiles

Aluminum blinds are ventilation and light control devices made from aluminum alloy, widely used in areas such as building facades, windows, and glass partitions. Commonly fabricated from alloys 3003, 6061, and 6063, they are typically customizable in various oxide/spray colors like natural aluminum, white, wood grain, and black.

Aluminum louvers profiles

Aluminum louvers profiles- Fixed aluminium louvres

- Adjustable Aluminum Louvers

- Exterior Aluminium Louver

- Aluminum Weatherproof Louvers

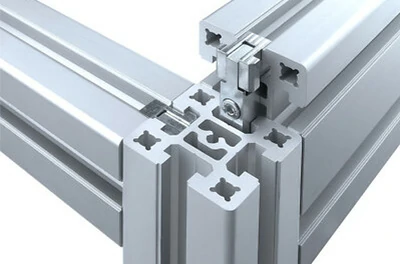

Structural aluminum extrusions

Heavy duty aluminium profiles

Heavy duty aluminum profiles are high-strength aluminum extrusions used in applications requiring high load-bearing capacity and structural strength, such as building frames, bridges, and large structural components. They exhibit excellent mechanical properties and durability, commonly fabricated from alloys 6061, 6082, and 7075.

Heavy duty aluminium profiles.

Heavy duty aluminium profiles

Heavy duty aluminium profiles- Aluminum Structural Beams

- Aluminum Structural Columns

- Aluminum Cantilever Balconies

Aluminum cantilever structures

Cantilever structures are fixed at one end to the building main structure, while the other end is suspended, providing open space or extended functional areas. They are commonly used in structures such as balconies, roofs, footbridges, and billboards that require suspended support.

Aluminum cantilever structures

Aluminum cantilever structures- Aluminium Cantilever Balconies

- Aluminium Cantilever Bridges

- Aluminium Cantilever Sign Structures

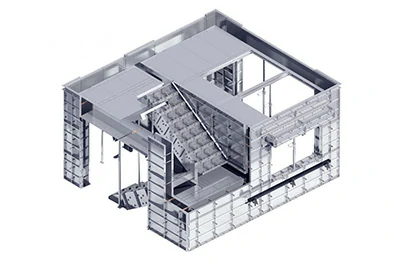

Aluminum formwork

Architectural aluminum formwork is a modular system used for constructing concrete structures. It is lightweight, high-strength, easy to install, and has a high reuse rate, making it a significant asset in modern construction projects. Commonly used alloys include 6061-T6 and 6082-T6.

- Aluminum formwork

- Aluminium Formwork Standard Panels

- Aluminum Column Formwork

- Aluminium Stair Formwork

Aluminum roof profiles

Aluminum roofing profiles are a type of aluminum profile system used for constructing building roof structures. They are commonly employed for structural support and covering materials (aluminum corrugated sheets), providing drainage and waterproofing functions for the roof. Structural supports are typically made from alloys like 6061, 6063, 7003, and 7005, while covering materials commonly use alloys such as 3003 and 5052.

Aluminum roof profiles

Aluminum roof profiles- Aluminum Roof Edges

- Aluminum Roof Beams

- Aluminum Roof Drainage Systems

- Aluminum Corrugated Sheets

Aluminium exhibition stand

Aluminum alloy exhibition stands are specially designed aluminum profiles used for constructing exhibition display systems. They are widely used to build various display structures such as booths, stands, and signage. These profiles are lightweight, durable, flexible in assembly, and reusable. Common alloys used include 6005A, 6061, 6063, and 7005.

Aluminium exhibition stand

Aluminium exhibition stand- Exhibition Aluminium Booth

- Aluminum Display Case

- Aluminium Profile Light Box

- aluminium shelving units

Aluminum sunroom profiles

The aluminum profiles used for sunrooms are structural systems made from lightweight aluminum alloy, known for their excellent weather resistance and corrosion resistance. Commonly used alloy for this purpose is 6063, which can undergo surface treatments such as powder coating and electrophoretic coating.

Aluminum sunroom

Aluminum sunroom- Aluminum Sunroom Frame

- Aluminum Sunroom Roof Structure

- Aluminum Sunroom Connectors

Aluminum partition profiles

Aluminum partition profiles are used to construct interior partition walls and dividing systems. They are characterized by their lightweight, high strength, and multifunctionality, allowing for flexible space partitioning solutions that can be freely combined and designed according to requirements.

Aluminum partition profiles

Aluminum partition profiles- Aluminum Vertical Profiles

- Aluminum Horizontal Profiles

- Aluminum Door Profiles

Shower enclosure qluminum profiles

Shower enclosure aluminum profiles are aluminum alloy profiles used to make shower enclosure frames and structures. They are characterized by their lightweight, corrosion resistance, and high strength. Commonly used alloys include 6005, 6061, 6063, and 6463. Various surface treatments such as anodizing, powder coating, and electrophoretic coating are available options.

Shower enclosure aluminum profiles

Shower enclosure aluminum profiles- Shower Enclosure Frame Profiles

- Shower Enclosure Track Profiles

- Shower Enclosure Wall Jamb Profiles

- Shower Enclosure Corner Profiles

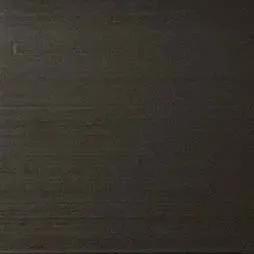

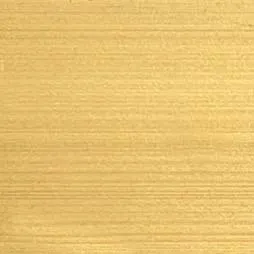

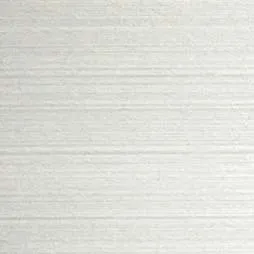

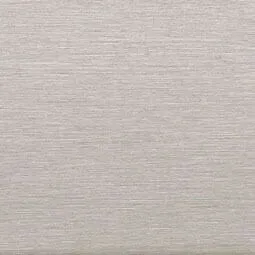

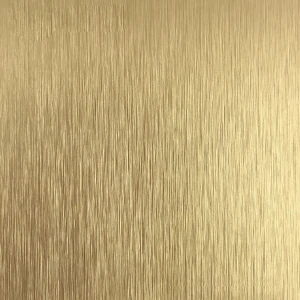

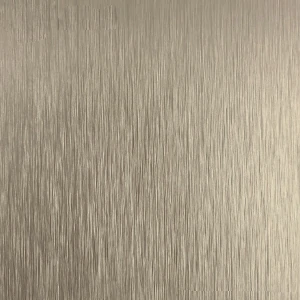

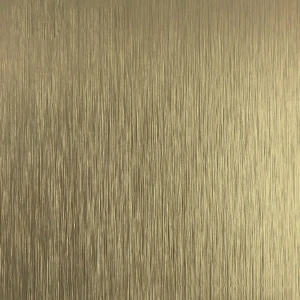

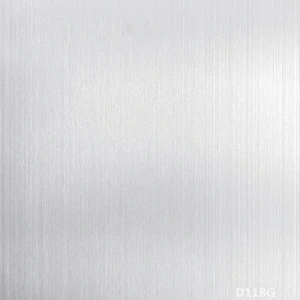

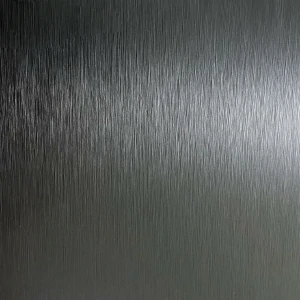

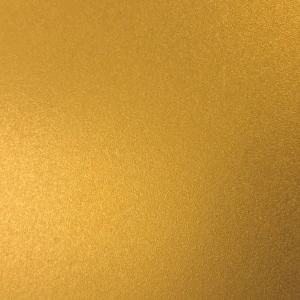

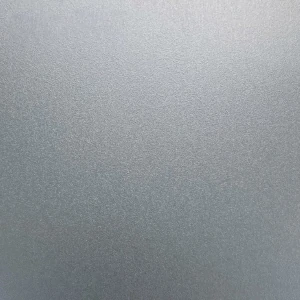

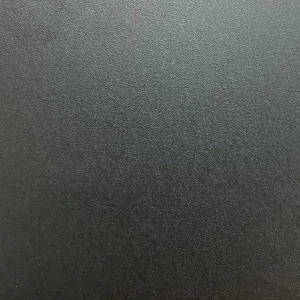

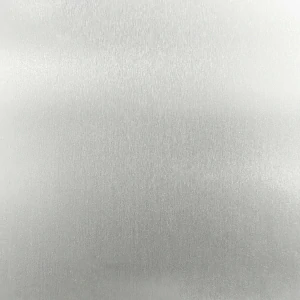

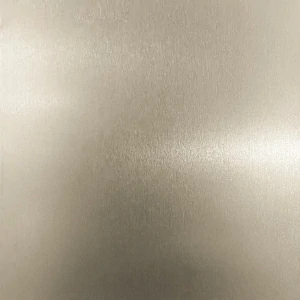

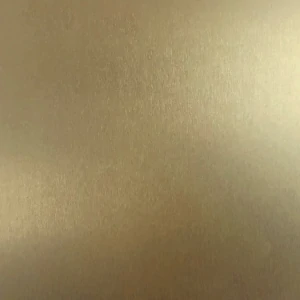

Mastar can provide you with surface treatment options

Aluminum profiles, serving as semi-permanent structures, are widely utilized in various architectural settings such as convention centers, airports, stations, and commercial buildings. Enhancing the corrosion resistance and durability of aluminum profiles not only ensures longevity but also allows for sleek, modern aesthetic designs, thereby enhancing the visual appeal of buildings.

Mastar provides the following surface treatment methods:

AnodizingMastar - your one-stop supplier for architectural aluminum profiles

One-stop procurement: We offer comprehensive services from profile design, customization, processing, surface treatment, to sea freight delivery, allowing you to complete projects effortlessly without spreading your resources.

Extensive product selection: We have a wide range of architectural aluminum profiles including standard profiles, custom profiles, and a complete set of molds to meet various project needs.

Customized solutions: Our design team can tailor solutions according to your requirements and environment, ensuring you get the best design and functionality.

Diverse surface treatments: We provide multiple surface treatment options including polished finish, clear anodizing, electrolytic anodizing, powder coating, PVDF painting, and wood grain finishes, giving you more choices.

Secondary processing advantages: Mastar offers free profile cutting services to ensure profiles meet your length requirements, along with drilling, milling, bending, and other processing services.

Pre-delivery inspection: Mastar strictly adheres to quality control standards, ensuring every batch of aluminum profiles undergoes comprehensive inspection and testing before delivery. This means you can confidently purchase our products, enjoying the assurance of guaranteed quality to ensure smooth project execution.

High-quality after-sales service: We prioritize customer satisfaction, providing prompt responses and attentive after-sales service to ensure your peace of mind in choosing and using our products.

Bulk purchase price advantage: With a well-established supply chain and production system, we offer competitive prices to help you achieve greater economic benefits in bulk purchases.

The optimal choice in the construction industry: aluminum profiles vs. steel profiles

Aluminum profiles and steel profiles each have their advantages in the construction field. Aluminum profiles, known for their lightweight, corrosion resistance, and high ductility, are suitable for applications such as high-rise buildings, modern architecture, and coastal structures that require complex cross-sections and lightweight structures. On the other hand, steel profiles excel in high strength and load-bearing capacity, making them ideal for industrial buildings, bridges, and large-span structures that require heavy-duty support.

Here's a detailed comparison between the two:

| Properties | Aluminum profiles | Steel profiles |

| Weight | Light, density about 2.7 g/cm³ | Heavy, density about 7.85 g/cm³ |

| Corrosion resistance | High, resistant to humidity and acid rain, suitable for harsh environments | Low, easy to rust, need surface treatment and regular maintenance |

| Strength | Medium, suitable for lightweight structures | High, suitable for heavy structures and buildings with high load-bearing requirements |

| Formability | Good, can be processed by extrusion, rolling, forging, stamping | Good, but high processing energy consumption |

| Surface treatment | Various, can be anodized, sprayed, electrophoretic coated, etc. | Mainly galvanized, painted, etc. |

| Plasticity | High, can be made into complex shapes and cross-sections | Low, difficult to make complex shapes |

| Durability | Long, low maintenance cost | Medium, need regular maintenance and coating protection |

| Cost | Higher, but low maintenance cost | Low, but high long-term maintenance costs |

| Environmental impact | High recyclability, environmentally friendly production process | High recyclability, but high production energy consumption |

| Application scenarios | High-rise buildings, modern buildings, coastal buildings, etc. | Industrial buildings, bridges, large-span structures, etc. |

Frequently asked Qs

Q: What are the common alloys used for architectural aluminum profiles?

A: Commonly used alloys for architectural aluminum profiles include 6061, 6063, and 6082. These alloys possess excellent mechanical properties and corrosion resistance, suitable for various applications in the construction industry.

Q: What is the hardness of architectural aluminum profiles?

A: Architectural aluminum profiles generally have two common hardness grades: T5 and T6. T5 typically achieves a hardness of 8-12 on the Vickers scale, while T6 reaches around 13.5. These hardness levels enhance the strength, rigidity, and durability of aluminum profiles, ensuring extended longevity.

Q: What is the typical thickness range of architectural aluminum profiles?

A: The thickness of architectural aluminum profiles typically ranges from 0.9 mm to 2 mm. Thickness may vary depending on the brand and specific application requirements. Users should select an appropriate thickness to ensure material rigidity and suitability.

Q: What surface treatment options are available for architectural aluminum profiles?

A: Common surface treatments for architectural aluminum profiles include anodizing, powder coating, electrophoretic coating, brushing, and wood grain transfer printing. These treatments not only enhance corrosion resistance but also offer a variety of color and texture options.

Q: What is the cost-effectiveness of architectural aluminum profiles?

A: Aluminum profiles offer high cost-effectiveness, with installations lasting 20 to 30 years without concerns of deformation, termite damage, or corrosion. Additionally, maintenance costs are low, requiring only simple cleaning to maintain optimal condition.

Q: How is the fire resistance of architectural aluminum profiles?

A: Aluminum profiles exhibit good fire resistance. Despite aluminum's low melting point, optimized surface treatments and design ensure structural stability during fires, providing a certain level of fire protection.

Q: What information is required when ordering architectural aluminum profiles from Mastar?

A: When ordering extruded aluminum structural profiles, please specify alloy, temper, length, quantity, surface finish requirements, intended use, as well as any special requirements regarding tolerances, delivery, packaging, and certifications. Providing design drawings, if available, will help us better meet your needs.