We offer a variety of custom and standard shapes of extrusions. Our standard aluminum extrusion catalog includes T-sections, U channels, H channels, angles, aluminum hat channels, and more.

Our standard aluminum extrusions have short production lead times and fast shipping. We also offer highly competitive bulk pricing to help you maximize your budget savings.

Standard aluminum profile specifications

Standards: ASTM B308, ASTM B429, EN 573-3, EN 755, EN 12020-2

Certifications: ISO, IATF, RoHS, CE, NADCAP

Wide range of product options

We offer a variety of standard aluminum extrusions to meet your specific requirements.

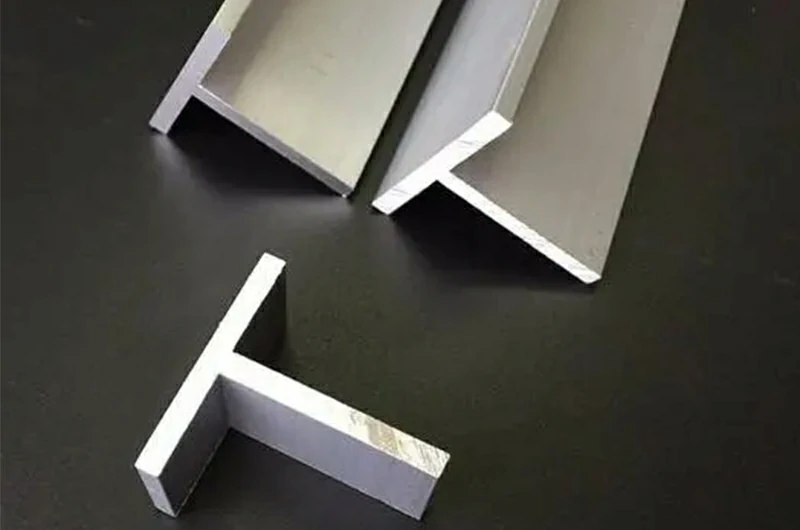

- Aluminium T-Section

- Aluminum T-Section features excellent corrosion resistance, weldability, and high load-bearing capacity. It is manufactured with high precision, stable dimensions, and tight tolerances.

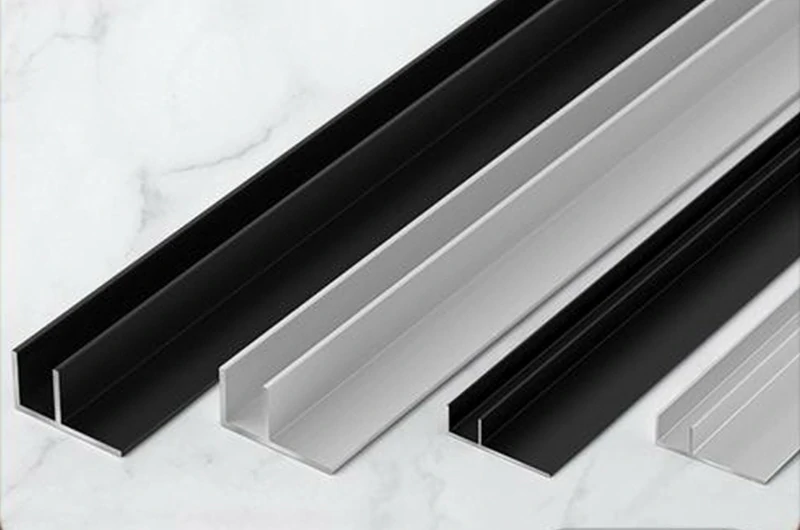

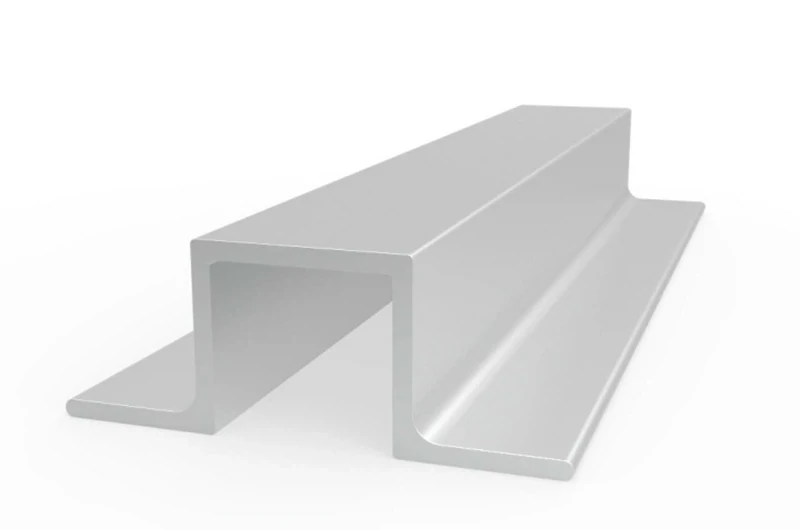

- Aluminum U Channel

- Aluminum channels, also known as "U-channels," are highly regarded for their lightweight, high strength, corrosion resistance, and ease of processing.

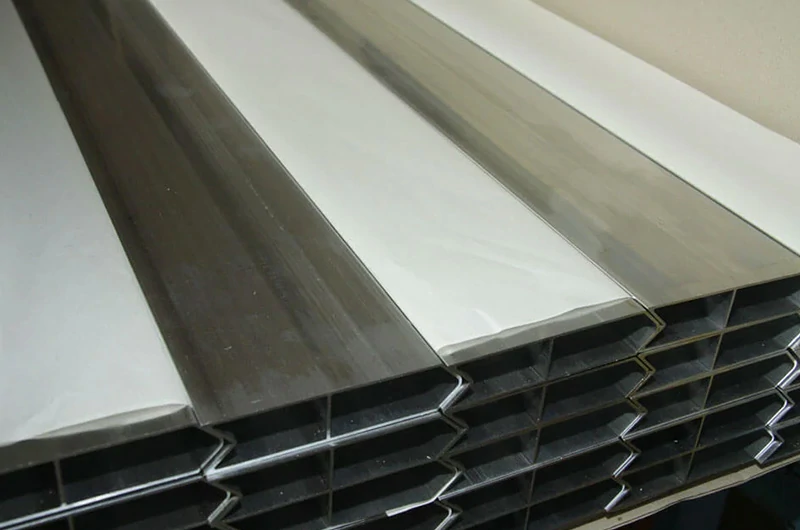

- Extruded Aluminum H Channel

- Aluminum alloy H-channels have the advantages of being lightweight, having high strength, being corrosion-resistant, easy to process, and suitable for surface treatments.

- Aluminium Z Section

- Aluminum Z-sections are commonly used in general engineering, maintenance projects, and DIY projects. They are known for being lightweight, strong, and corrosion-resistant.

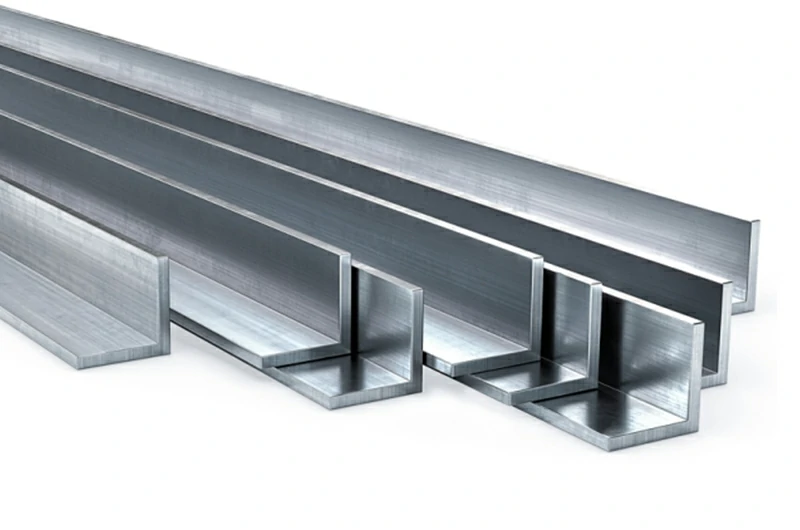

- Aluminium Angle

- Angle aluminum, also known as aluminum angle bars, aluminum angles, or aluminum trim, has legs that can be equal or unequal in length, providing stability and rigidity in various applications.

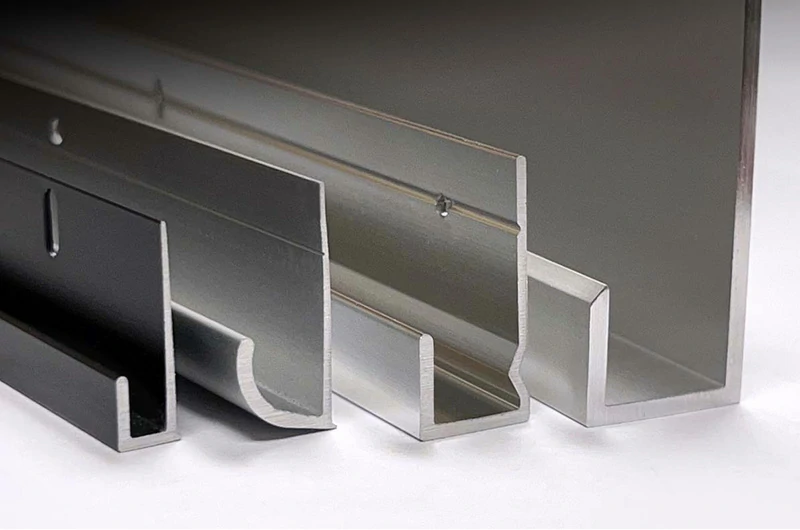

- Aluminum F Channel

- Aluminum F-channels, shaped like the letter "F," come in various shapes, sizes, and surface finishes, including 3/4", 1/4", and 5/16".

- Aluminum J Channel

- Aluminum J-channels, shaped like the letter "J," are commonly used for mirror and glass installations.

- Aluminum Hat Channel

- Aluminum hat channels have a cross-section similar to a "hat." Their unique structure includes two horizontally extending edges (the hat's brim) and two vertical sides (the hat's sides), with a flat horizontal surface on top.

Aluminum alloys and their applications for standard extrusions

6063 aluminum standard extrusions

Characteristics: 6063 aluminum alloy offers good extrudability and moderate strength, with a high-quality surface finish.

Applications: Suitable for architectural applications such as door and window frames, curtain wall systems, decorative components, and parts with thin-walled complex designs.

6061 aluminum standard extrusions

Characteristics: 6061 offers excellent extrudability and weldability.

Applications: Used for structural components such as frames, pipelines, bridges, ships, and aerospace structures.

3003 aluminum standard extrusions

Characteristics: 3003 has higher strength than 1100 but lower ductility, with good corrosion resistance and formability.

Applications: Commonly used in extruded operations for heat exchanger tubes, and in products requiring moderate strength and good corrosion resistance such as cookware, storage tanks, and pressure vessels.

2024 aluminum standard extrusions

Characteristics: 2024 offers high yield strength and tensile strength.

Applications: Mainly used in high-strength components in aerospace and military applications, such as wings and fuselage structures, landing gear, and more.

7075 aluminum standard extrusions

Characteristics: 7075 has superior yield strength and tensile strength, with poor weldability but good machinability.

Applications: Suitable for applications requiring extremely high strength, such as aircraft structural parts, military equipment, extreme sports equipment, and components in high-stress environments.

Multiple advantages of standard extruded aluminum profiles

- Excellent strength-to-weight ratio, strong yet lightweight.

- High corrosion resistance.

- Good electrical and thermal conductivity.

- Low manufacturing costs and affordable material prices.

- Easy to process, suitable for complex cross-sections and uneven thickness shapes.

- Seamless forming without the need for joints or welding.

Design tips: improving efficiency and quality

Feel free to discuss your needs with us; we can help you determine the optimal overall design.Quick Quote

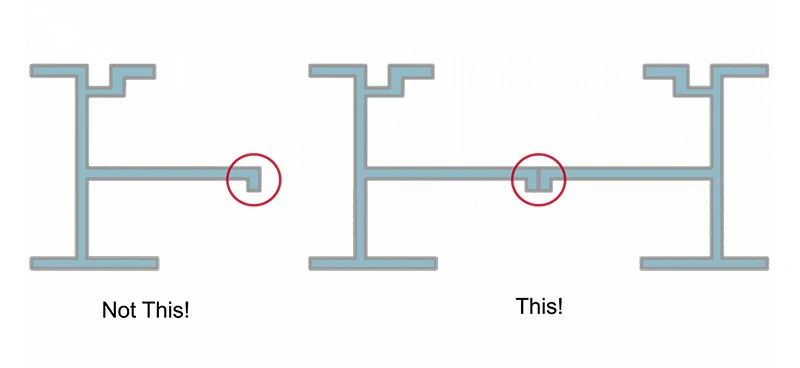

Practice symmetry

In aluminum profile design, maintaining symmetry is crucial. Symmetrical designs not only enhance product stability but also significantly reduce the risk of die tongue breakage.

Choose wall thickness wisely

Variations in thickness can lead to extrusion deformation, die breakage, or surface defects. Additionally, it's important to note that extruding thicker walls is less costly, while extruding thinner walls is more expensive.

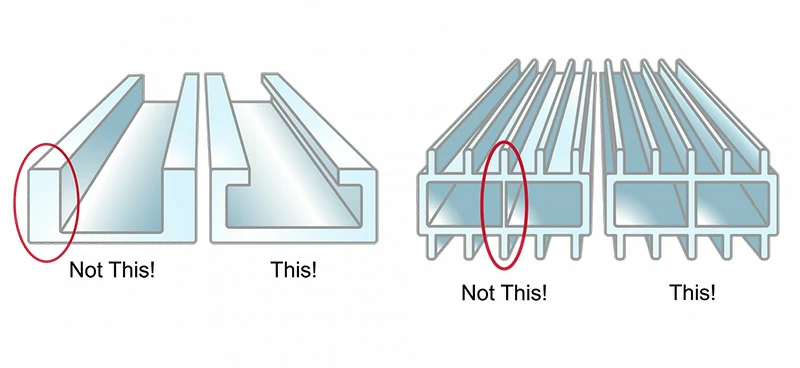

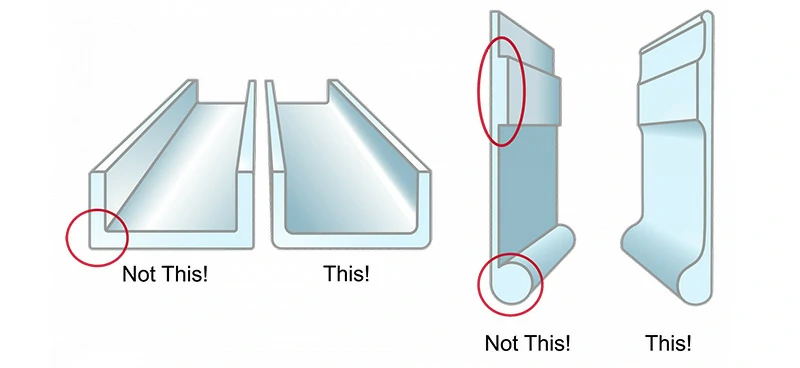

Smooth all transitions

Smooth transitions and rounded corners in the design not only enhance the aesthetics of the aluminum profile but also improve its durability.

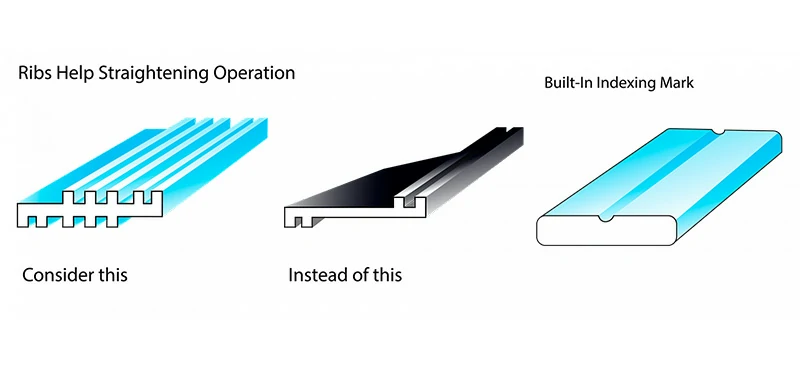

Enhance visual appeal

Using grooves and ribs is an important way to enhance the visual appeal of aluminum profiles. These design elements not only increase the aesthetic value but also improve ease of handling.

How can we process the surface of standard extruded profiles?

- Powder Coating

- Anodizing

- PVDF Coating

- Electrophoresis

- Polishing

- Sandblasting

- Silver Plating

- Brushed Finishes

Value-Added services, free and exceptional benefits

- CNC Machining

- Drilling

- Precision Cutting

- Welding

- Milling

- Bending

- Assembly

- Custom Aluminum Processing

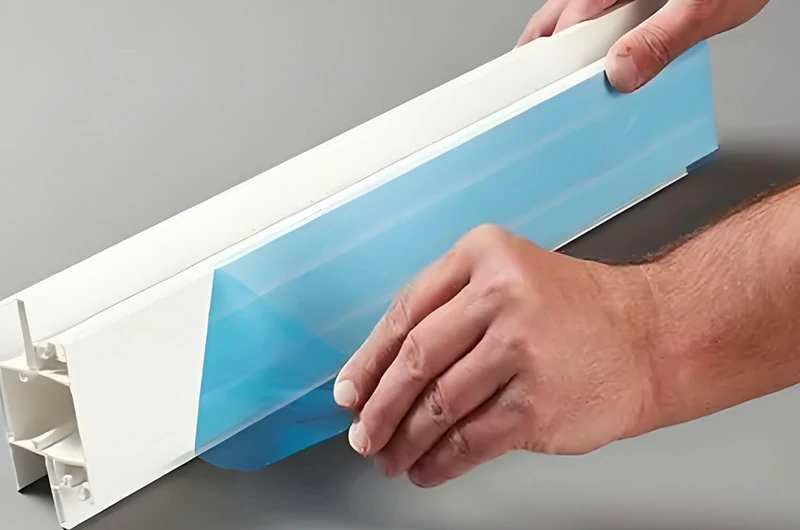

Superior product packaging to ensure safe transportation

We offer a variety of packaging options to meet our customers' needs.Quick Quote

How to order standard extruded aluminum profiles

When placing an order, please provide as much information as possible, including the alloy, temper, dimensions, quantity, surface treatment, final application, and any special instructions regarding tolerances, delivery, packaging, and certification.

Sharing design drawings will also help us provide a quicker and more accurate quote.