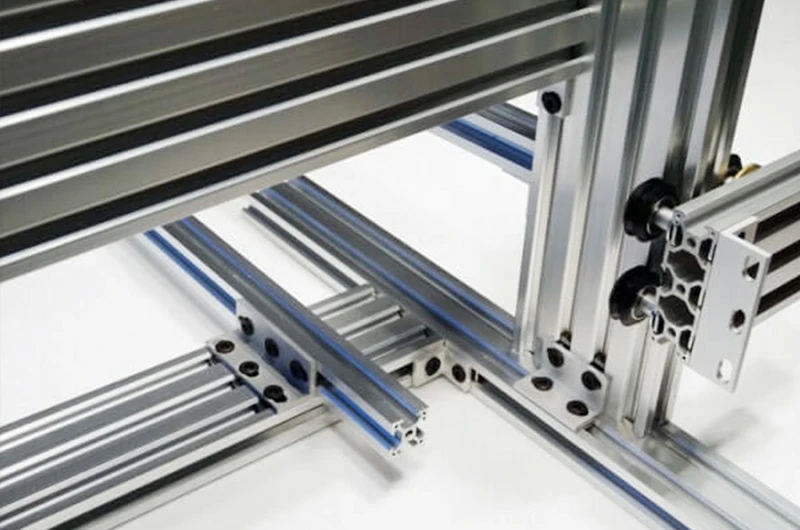

Assembly Line Aluminum Profiles are known for their high strength, strong load-bearing capacity, modular design, and ease of assembly and expansion, making them essential components in industrial production lines. Whether for automotive assembly, electronics manufacturing, or food processing, Mastar's high-quality aluminum profiles meet diverse customer needs.

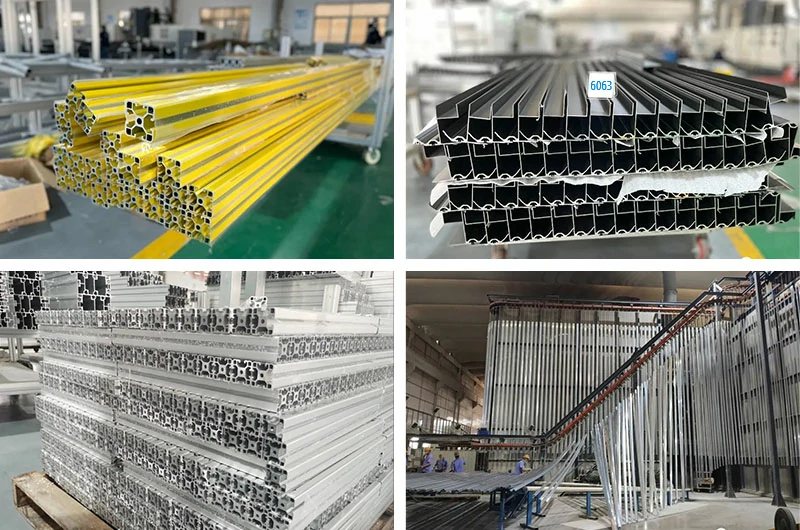

Mastar provides comprehensive purchasing services, bundling and selling all assembly line aluminum profiles. Our aluminum profiles come in various sizes with ample inventory, competitive pricing, bulk purchase discounts, and personalized packaging options.

Specifications for assembly line aluminum profiles

Alloys: 6063, 6061, 6082

Thickness: 0.5-2.0mm (customizable sizes available)

Length: 6m, 9m (cut to any desired length)

Surface treatment: powder coating, anodizing, polishing

Processing: cutting, drilling, tapping, CNC machining, bending, assembly

Connection methods: internal connection, external connection (click to read more content about the profile joint)

Standards: ASTM B221, EN 755-2, EN 573-3, TS EN 755-2

Certifications: CE, RoHS, ISO, UL, SGS

Packaging: bundle packaging, wooden crate packaging (custom packaging available upon request)

Popular assembly line aluminum profile products

As aluminum suppliers, we offer a one-stop service, gathering various aluminum profiles and bundling them for sale as high-quality assembly line materials. Quick Quote

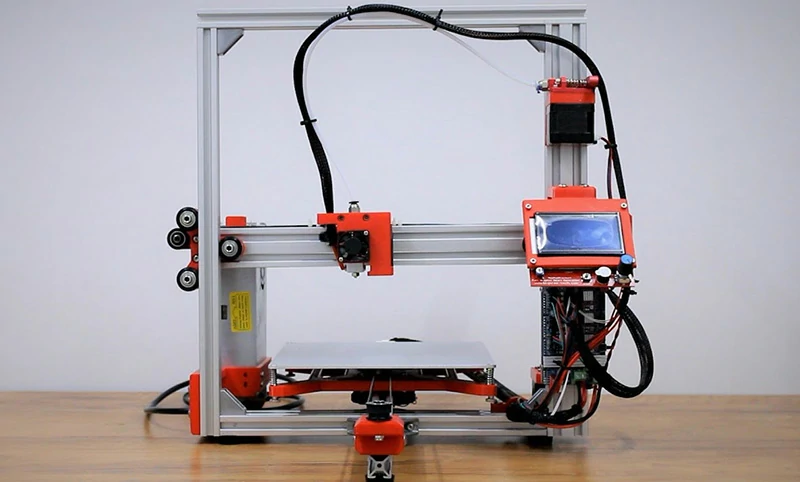

- T-slot profiles

- T-slot aluminum profiles come in over 120 different cross-sectional designs, offering precise dimensions, high strength, and excellent load-bearing capacity.

- Customers can customize their configurations by adding or removing components without the need for welding.

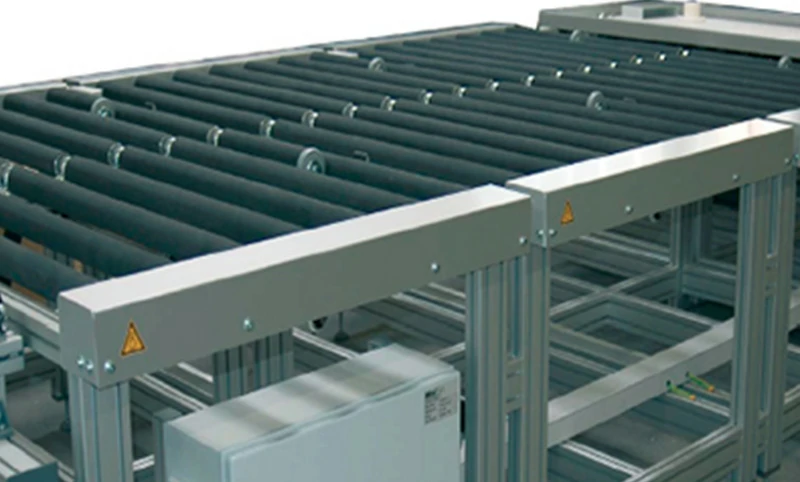

Aluminum extrusion rails

Aluminum extrusion rails- Aluminum extrusion rails come in two versions: tracks and clamps, suitable for various load requirements.

- Designed based on aluminum profiles, they are easy to integrate and install.

- Aluminum channel

- U-shaped and H-shaped profiles are suitable for cable routing in frame designs, offering both aesthetic appeal and high functionality. They feature flexible design options, minimal parts, and easy installation.

- Aluminum tube profiles

- Aluminum tube profiles are an ideal choice for assembly lines due to their lightweight, high strength, and corrosion resistance.

- Common outer diameter sizes include 20 mm, 25 mm, 30 mm, 40 mm, and 50 mm, with wall thickness ranging from 1 mm to 3 mm.

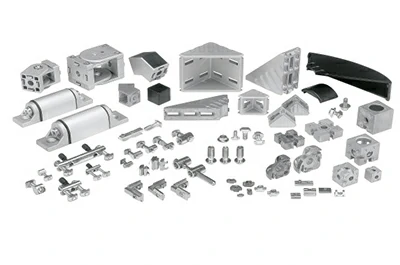

Fasteners and accessories

Fasteners and accessories- We offer approximately 30 types of connectors and over 300 varieties of aluminum bolts, self-tapping bolts for aluminum, and self-tapping screws for aluminum.

- All fasteners and accessories undergo rigorous testing to ensure high performance and durability.

Popular sizes of assembly line aluminum profiles

Mastar offers a wide range of aluminum profile sizes to meet various application needs.

- 4040 aluminum extrusion

40mm X 40mm

The most commonly used specifications for workshop assembly lines are secure, stable, and easy to assemble and disassemble.

- 2020 aluminum extrusion

20mm X 20mm

Suitable for lightweight frames, equipment supports, partitions, storage racks, and other simple structures.

- 3030 aluminum extrusion

30mm X 30mm

Suitable for light-duty equipment or storage racks with moderate load-bearing requirements.

- 4080 aluminum extrusion

40mm X 80mm

Used for workshop assembly line workbenches, featuring sturdy construction and strong load-bearing capacity.

- 4545 aluminum extrusion

45mm X 45mm

Slot and hole profiles are more specialized and are also known as flower-shaped aluminum profiles.

- 6060 aluminum extrusion

60mm X 60mm

Large-scale structural frameworks suitable for heavy-duty industrial applications.

We also offer 5050 aluminum extrusion, 8080 aluminum extrusion, 9090 aluminum extrusion, 100100 aluminum extrusion, 2020 aluminum extrusion, aluminum channels, aluminum tubes, aluminum rods, angle aluminum, and other assembly line aluminum profiles. Quick Quote

Advantages of assembly line aluminum profiles

- High strength, strong load-bearing capacity, stable structure, durable.

- Various surface treatments, aesthetic and corrosion-resistant.

- Modular design, easy assembly and expansion without welding.

- Lightweight, reducing structural load and transportation costs.

- Anti-static design, suitable for industries with high electrostatic requirements such as electronics manufacturing.

- Heat-resistant, suitable for operational needs in high-temperature environments.

Common application of assembly line aluminum profile

Industrial assembly line aluminum profiles are widely used in automotive assembly workshops, air conditioning and appliance factories, mobile phone manufacturing lines, robotics, aircraft automated manufacturing, food production workshops, cosmetic production lines, and other fields.

Why choose Mastar

- Mastar offers one-stop purchasing services, providing packaged sets of aluminum profiles including nuts and components to meet various customer needs.

- Mastar's aluminum profiles can be combined with profiles from other manufacturers, enhancing application flexibility.

- Mastar strictly controls the iron content in raw materials to ensure extrusion quality.

- Mastar maintains ample inventory and offers a variety of mold sizes.

- Mastar's products are competitively priced, with discounts available for bulk purchases.

- Mastar provides personalized packaging solutions tailored to customer requirements, ensuring products arrive intact at their destination.

Assembly line aluminum profile anodizing color

In the market, assembly line aluminum profiles are generally available in silver-white and black. Other colors such as champagne, yellow, green, and grey can be customized based on demand.

Custom-colored aluminum profiles typically command higher prices compared to standard silver-white and black options.Quick Quote