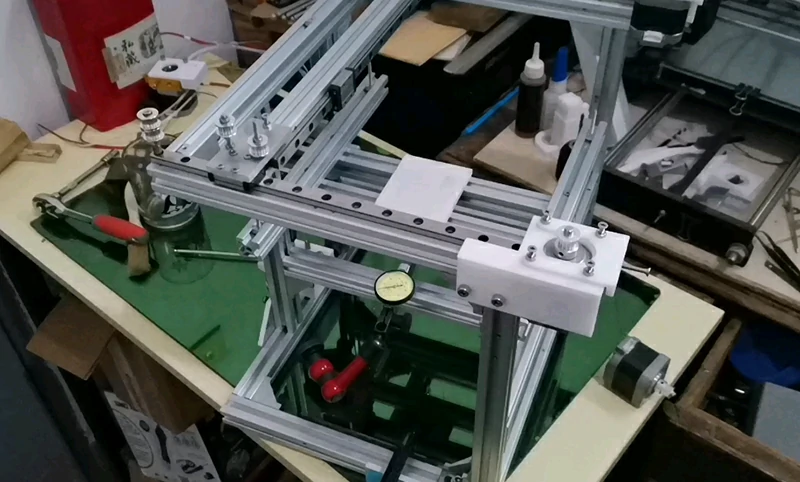

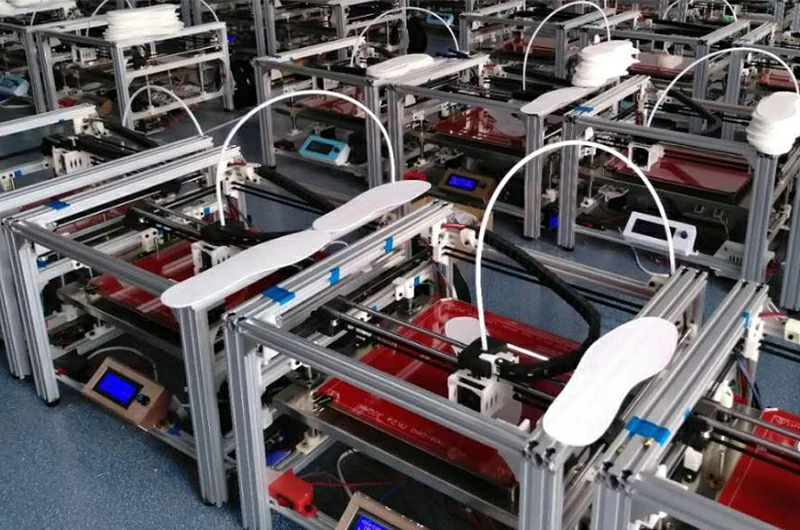

Aluminum profiles play a vital role in the manufacturing of 3D printers, primarily utilized for components such as the structural frame, support brackets, guide rails, and heated bed supports. MASTAR prioritizes user experience and product quality, striving to provide our collaborating customers with the best product quality and lowest production costs.

Specification of 3D printer aluminum profile

Alloy selection: aluminum alloys such as 6061, 6063, 6082, and others in the 6000 series are suitable for extrusion.

Best-selling products: T-slot, V-slot, aluminum alloy accessories.

Popular sizes: 15*15, 20*20, 20*40, etc.

Surface treatment: anodizing, powder coating, etc., with black anodized finish being popular.

Additional services: drilling, cutting, etc.

MASTAR aluminum profiles for 3d printers

- 15*15 MakerBeam XL Aluminum Extrusion

- 20*20 Aluminum Extrusion

- 20*100 Aluminum Extrusion

- 20*40 2040 v-slot Aluminum Extrusion

- 2060 Aluminum Extrusion

- 2060 v-slot Aluminum Extrusion

- 2080 v-slot Aluminum Extrusion

- 3030 Aluminum Extrusion

- 4040 Aluminum Extrusion

- 4040 v-slot Aluminum Extrusion

- 4080 Aluminum Extrusion

- C-Beam v-slot Aluminum Extrusion

- Anodized aluminum extrusion

- Anodized aluminum extrusion

- Anodized aluminum extrusion

MASTAR aluminum accessories for 3D Printers

- 3030 90 Degree Caster Foot Plate

- Gantry Plate Silver for 20 Series V-Groove Extrusion

- Silver Gantry Carriage Kit with Timing Belt

- 3030 90 Degree T Joining Plate

- Gantry Plate Black for 20 Series V-Groove

- T-slot Straight Link Connector 3030 Inside bracket

- M5x35 Button Head Hex Screws

- 8mm Pipe Bracket - 10 Pack

- 3030 Extrusion T Bracket

- 3D Printing M3 T Nuts For 20 Series

- 2020 Aluminum L Bracket (Black)

- 3D Printing M8 T Nuts For 40 Series

Advantage of MASTAR aluminum profile for 3D printer

- Precision motion: MASTAR's aluminum extrusions with V-groove design perform exceptionally well in precise linear motion applications. Their unique shape is specifically designed to accommodate V-wheels, ensuring smooth and accurate movement for projects requiring reliable motion control.

- High-quality materials: our extrusions are made of 6063 T-5 aluminum, known for its impressive strength-to-weight ratio and durable characteristics. This advanced aluminum ensures a sturdy yet lightweight structure suitable for various applications.

- Multiple surface finishes: our transparent and black anodized finishes enhance material durability and provide a seamless aesthetic that complements your project design.

- Easy assembly: the T-slot design of MASTAR aluminum extrusions facilitates simple assembly. This design is compatible with various connectors and accessories, offering flexibility and efficiency to simplify construction processes to meet your specific requirements.

- Versatility: MASTAR aluminum extrusions are designed to be compatible with V-slot and T-slot systems, enabling them to adapt to a wide range of applications.

- Customization: MASTAR aluminum profiles can meet your unique needs, offering customized lengths, miter cuts, and threading services to fully meet project requirements.

- Precision sizing: MASTAR aluminum extrusions are manufactured with precision, meeting exact dimensional specifications with strict tolerances, making it easy to assemble with compatible components and accessories.

MASTAR aluminum profile—suitable for a variety of 3D printers

- The structure of 3D printers adopts a V-slot profile

- Laser engraving machine

- CNC engraving machine

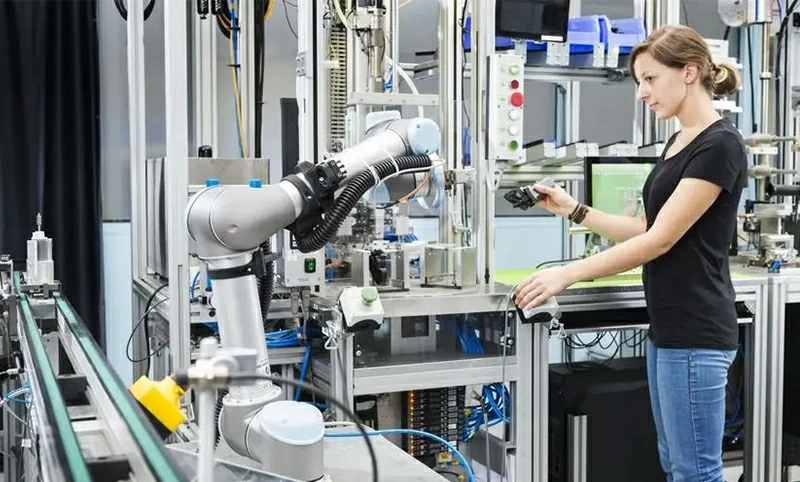

- Robotics technology

- DIY projects

- Customized machines

- Customized casings

- 3D printer casings

- Other applications

Choose MASTAR aluminum profile

When you choose MASTAR as your 3D Printer profile supplier, you'll gain access to extensive industry knowledge. In addition to high-quality aluminum products, you'll also receive excellent customer service and advice. Click on our email to contact us or visit our website for more technical product specifications.

- Quick delivery: we have ample inventory to ensure rapid delivery of any standard aluminum profiles, saving you time and ensuring the smooth progress of your project.

- Custom profiles: in addition to standard aluminum profiles, MASTAR can provide customized profiles based on customer requirements for size and surface finish. Just let us know the alloy, length, quantity, surface smoothness, final usage, and any other special requests.

- High-quality products: our products meet standards and certifications, featuring modern design, high hardness, resistance to bending, rust, and insect infestation.

- Competitive pricing: our product prices are competitive, and we offer reasonable discounts for bulk orders, ensuring you get better prices and superior service.

- After-Sales Support: We provide prompt after-sales support to ensure you receive timely assistance and support when using our products.

Purchase guide for 3D printer aluminum profiles

Compared to other manufacturing processes, what are the advantages of using aluminum extrusion for 3D printers?

Our mission is to provide customers with the best solutions for aluminum extrusion 3D printers.

- Cost-effectiveness: Aluminum extrusion is a cost-effective process that can produce complex shapes with minimal waste.

- Versatility: Aluminum extrusion can be used to manufacture various shapes and sizes, making it a versatile manufacturing process.

- Strength: Aluminum extrusion is a sturdy and durable process that can produce parts with a high strength-to-weight ratio.

- Design flexibility: Aluminum extrusion allows for a wide range of design possibilities, allowing for complex shapes and intricate details.

- Speed: Aluminum extrusion is a fast process that can efficiently produce parts.

- Recyclability: Aluminum is a recyclable material, making aluminum extrusion an environmentally friendly process.

Can aluminum extrusion products be drilled and tapped for secondary processing?

MASTAR can provide drilling and tapping for aluminum extrusion products. Depending on the size and complexity of the product, MASTAR can offer additional machining services according to customer requirements, making your 3D printer project more convenient.

Can decorative features be added to extruded products?

As a professional supplier of 3D printer profiles, we highly value this detail. MASTAR provides aluminum profiles for 3D printers, which can undergo surface treatments such as anodizing and coating to ensure the aesthetics of the 3D printer profiles.

Can aluminum extrusion 3D printers be used in corrosive environments?

MASTAR aluminum extrusion parts can be used in corrosive environments. Aluminum is a corrosion-resistant material, and when used in extrusion, it can be further protected through various coatings and finishes. Coatings and finishes help protect aluminum from corrosion and other environmental factors.