Aluminum alloy pipes are widely used in industry and construction, and there are obvious differences between thin-walled pipes and thick-walled pipes in terms of wall thickness, strength, weight, cost, performance and use.

Understanding the different characteristics of aluminum alloy thin-walled and thick-walled pipes can help you make informed decisions when designing and selecting materials to meet project needs and achieve optimal performance.

Definition of thin wall pipe and thick wall pipe

Aluminum thin wall pipe

Aluminum thin wall pipe- Aluminum alloy thin-walled pipes refer to aluminum alloy pipes with relatively thin wall thickness, and usually the ratio of wall thickness to pipe diameter is small. This type of pipe is suitable for applications that require light weight and low strength requirements, and can effectively reduce the weight of the structure.

- Minimum wall thickness: 0.25mm.

Aluminum thick wall pipe

Aluminum thick wall pipe- Refers to aluminum alloy pipes with relatively thick wall thickness, and the ratio of wall thickness to pipe diameter is large. This type of pipe is usually used in situations that require higher strength and pressure resistance, and can withstand greater external pressure and load.

- Maximum wall thickness: 100-250mm.

The difference in alloy selection

| Alloy series | Commonly used alloy grades | thin wall tube | thick wall tube | Features |

| 1000 | 1050, 1100 | √ | Better ductility and formability | |

| 2000 | 2024, 2014 | √ | High strength, excellent fatigue strength and processability | |

| 3000 | 3003, 3004 | √ | Good corrosion resistance and weldability | |

| 5000 | 5052, 5083 | √ | High strength and good corrosion resistance | |

| 6000 | 6061, 6063 | √ | √ | Excellent mechanical properties and strength |

| 7000 | 7075 | √ | Extremely high strength and hardness |

Performance differences

| Features and performance | Thin wall tube | Thick wall tube |

| Strength and stiffness | Lower strength and stiffness, suitable for lightweight structures or applications with higher weight requirements | High strength and stiffness, suitable for occasions that need to bear larger loads or provide structural support. |

| Flexibility and deformation | More flexible, more prone to deflection and deformation, providing greater flexibility and adaptability in certain applications. | It has higher stiffness, stronger resistance to flexibility and deformation, and is more suitable for occasions requiring stability and support. |

| Pressure resistance | Generally has a low pressure- bearing capacity and is not suitable for withstanding high-pressure liquids or gases. | Able to withstand greater pressure, suitable for high-pressure liquid or gas transmission systems. |

| Corrosion resistance | Because the material is thin, it may perform poorly in corrosive environments and requires additional protection. | Because the material is thicker, it generally has better corrosion resistance and is suitable for harsh environments. |

| manufacturing cost | Thin-walled tubes use relatively less material and generally have lower production costs. | The production cost of thick-walled pipes is relatively high because more material is required, but in some specific engineering situations, thick-walled pipes may provide a more economical solution. |

Manufacturing process difference

Thick-walled pipes are relatively easy to process, but the influence of wall thickness also needs to be considered and appropriate processing techniques selected to ensure their internal and external quality.

Thin-walled tubes are more difficult to process because they are easily deformed due to their thin walls. Higher-precision processing equipment and technology are required in processes such as extrusion and stretching to ensure their dimensional accuracy and surface quality.

Application areas and aluminum tube selection

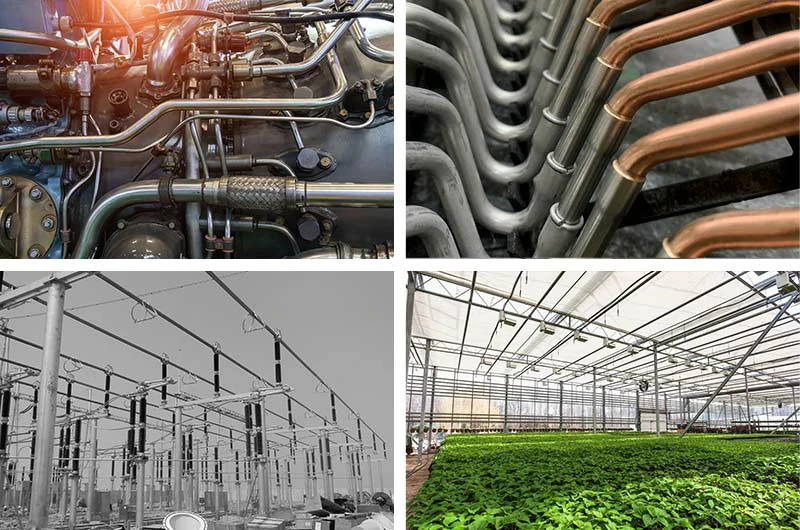

Thin-walled tubes generally have a high strength-to-weight ratio and are suitable for applications requiring lightweight design, such as in the aerospace and automotive industries. Its lightweight characteristics enable it to meet structural strength requirements while reducing the overall weight.

Thick-walled pipes are usually used in engineering structures because of their large load-bearing capacity and are suitable for applications that require higher strength and pressure resistance, such as building support structures, mechanical equipment and other fields.

| Application areas | Application site | thin wall tube | thick wall tube | Commonly used alloys |

| Aerospace | aircraft frame | √ | 2024, 7075 | |

| landing gear | √ | 6061, 7075 | ||

| tank | √ | 3003, 5052, | ||

| car | Suspension parts | √ | 6061, 6063 | |

| engine parts | √ | 5083, 5052 | ||

| heat exchanger | √ | 1100, 3003 | ||

| ship | mast | √ | 5083, 6061 | |

| railing | √ | 5052 | ||

| architecture | truss frame | √ | 6061 | |

| scaffold | √ | 6063 | ||

| furniture | frame | √ | 6061, 6063 | |

| Bracket | √ | 6061, 6063 | ||

| leg | √ | 6061, 6063, | ||

| heat sink | Electronic component | √ | 1050, 1220 | |

| Bus pipe | √ | 1060, 6101 | ||

| heat exchanger | √ | 3003, 6063 | ||

| pipeline | irrigation pipes | √ | - | |

| oil and gas pipeline | √ | - | ||

| pressure vessel piping | √ | - |

※ 8 Tips for the production of thin wall aluminum tube pipe

- When sampling, it is necessary to check according to the drawing size, strictly control the wall thickness of the aluminum profile, and use a vernier caliper to check whether it is qualified.

- The molds are polished and improved to improve the surface quality of the aluminum profiles, and nitriding treatments are performed regularly to ensure sufficient preparation for the next production.

- Adjust the level of the discharging table and cooling bed before production to prevent the aluminum profiles from being scratched during movement and ensure product quality.

- Control the temperature during the extrusion process, including the temperature of the aluminum billet, container and mold, and adjust the speed according to the extrusion surface quality and process progress to ensure a smooth product surface.

- Pay attention to the surface quality and initial runout from the discharge port to the cooling bed to avoid defects such as scratches on the bottom surface, and adjust the height of the support wheel to prevent deformation of the aluminum profile.

- Reasonably arrange the spacing between aluminum profiles on the cooling bed to avoid collisions and scratches and ensure product quality.

- Control the straightening and sawing processes to avoid deformation and surface defects of aluminum profiles, and pay attention to cleaning aluminum chips to keep the product surface clean.

- Use special lifting tools to install the profile frame, keep intervals and observe the end quality to improve surface quality and avoid scratches, and ensure ventilation and aging conditions of the aluminum profile.