6101 aluminum busbars offer moderate strength and excellent corrosion resistance, making them easy to extrude. With their outstanding electrical conductivity and good mechanical properties, they are highly favored in electrical projects.

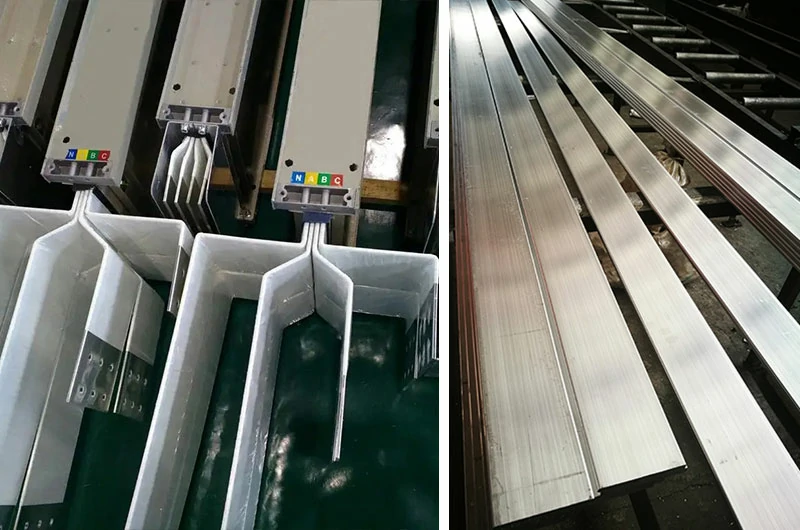

As a top-tier supplier of 6101 aluminum busbars, Mastar Metal boasts ample inventory and a complete range of specifications. We offer various shape options, including rectangular, rounded rectangle, R-angle, and semi-R-angle shapes.

6101 aluminum busbar specifications

| Alloy | 6101 |

| Temper | T61,T63,T64,T65 |

| Thickness | 2-20mm |

| Width | 30-130mm |

| Length | 3m/6m/12m,customizable cutting |

| Size Range | 230-20130mm |

| Conductivity | 59% IACS |

| Shape | Right angle, rounded corner, R angle (no burrs on edges) |

| Surface requirements | Smooth, no impurities, no color difference, no spots, no burrs on edges, uniform and dense coating |

| Surface treatment | Powder coating, anodizing, electroplating (tin plating/silver plating/nickel plating) |

| Insulation treatment | Dipping, powder coating, epoxy resin coating, heat shrink tubing, PVC tubing |

| Standards | ASTM B317, IEC 60105 |

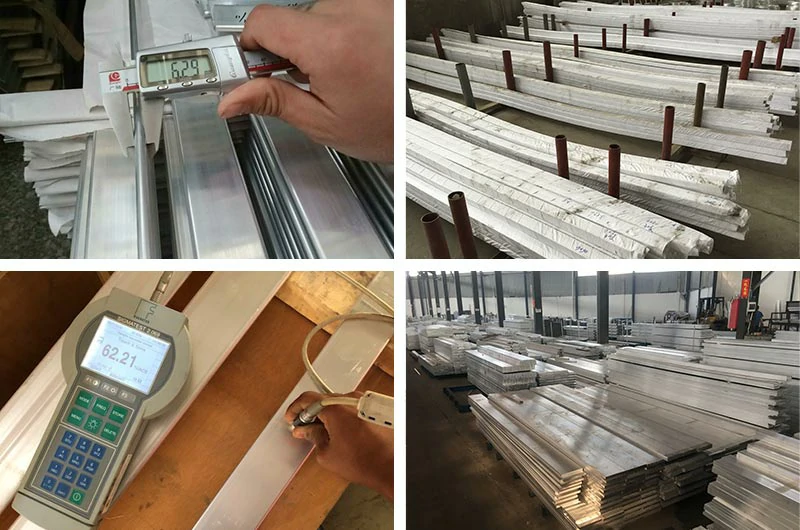

| Quality inspection | Dimension measurement, bending test, conductivity test, resistance test, etc. |

Temper of 6101 aluminum bus bar

6101-T6 Aluminum Bus Bar undergoes solution heat treatment and artificial aging, providing the highest strength and best mechanical properties.

6101-T61 Aluminum Bus Bar requires solution heat treatment and artificial under-aging treatment. Compared to other tempers, it has the lowest ductility but higher electrical conductivity.

6101-T63 Aluminum Bus Bar falls into an "intermediate" state, with electrical conductivity higher than T6 but lower than T61.

6101-T64 Aluminum Bus Bar is in a partially annealed state, featuring the highest electrical conductivity and optimal annealed condition, along with maximum formability.

6101-T65 Aluminum Bus Bar offers moderate electrical conductivity, controllable tensile and yield strength, aiding in controlling bending reproducibility.

Characteristics of 6101 aluminum bus bar

- High Conductivity: 6101 Aluminum Bus Bar exhibits excellent conductivity, effectively carrying electrical currents, crucial for distribution systems that require low resistance to reduce energy loss.

- Corrosion Resistance: 6101 Aluminum Bus Bar possesses good corrosion resistance, ensuring longevity and reliability, particularly in outdoor or high-humidity environments.

- Heat Resistance: While not a heat-resistant alloy, 6101 aluminum can adequately handle typical temperature variations encountered in electrical systems.

- Formability: 6101 Aluminum Bus Bar can be easily formed into various shapes and sizes to meet specific installation requirements.

- Weldability: 6101 aluminum can be welded using methods such as TIG and MIG, facilitating assembly and modifications of busbar systems.

- Lightweight: Compared to copper busbar conductors, aluminum busbars are lighter in weight, making them easier to handle and install, suitable for aerospace, automotive, and other industries.

Applications of 6101 aluminum bus bar

- Electrical busbar conductors and components

- Electrical panels and switchgear

- Distribution systems

- Power plants

- Substations

- Telecommunication equipment

- Railway systems

- Industrial machinery

- Aerospace

- Electric vehicle (EV) charging stations

- Electric vehicle hybrid power systems

- Battery packs

Quality supplier of aluminum bus bars - Mastar Metal

- Mastar Metal offers a variety of 6101 Aluminum Bus Bars with different tempers to meet your diverse needs.

- We maintain ample stock of commonly used aluminum bus bar specifications, enabling quick delivery and saving you time and costs.

- Mastar Metal provides comprehensive mechanical machining services tailored to customer project requirements, including cutting, punching, bending, and drilling.

- Our aluminum bus bars feature smooth surfaces, free from burrs or impurities, with excellent straightness.

- All Mastar Metal aluminum bus bars undergo a series of electrical tests, including conductivity and resistance checks, with a maximum current carrying capacity of up to 4000A, ensuring compliance with your project requirements.

6101 vs 6063 vs 1350 aluminum bus bar

6101 aluminum bus bars are similar to 6063 aluminum bus bars in alloy composition, with minor chemical variations, but they exhibit enhanced conductivity. Bus bars from the 6000 series are generally more robust and durable, commonly used in high-voltage transmission lines, transformer windings, motor windings, and structural support in buildings.

Compared to 1350 aluminum bus bars, 6101 aluminum bus bars offer higher yield strength and better creep resistance. With added magnesium and silicon, they possess high mechanical strength without significant reduction in electrical conductivity.

| characteristic | 6101 | 6063 | 1350 |

| alloy composition | Al-Mg-Si | Al-Mg-Si | Al |

| strength | high | medium | Low |

| conductivity | medium | high | high |

| Corrosion resistance | good | good | very good |

| Processability | good | good | very good |

| price | medium | medium | Low |

- 6101 Aluminum Bus Bars: Suitable for applications requiring high strength and corrosion resistance, such as power systems, electrical equipment, and building structures.

- 6063 Aluminum Bus Bars: Ideal for applications requiring good conductivity and machinability, such as wiring, bus bars, and heat sinks.

- 1350 Aluminum Bus Bars: Ideal for applications requiring high conductivity and corrosion resistance, such as power systems, electrical equipment, and electronic components.

Detailed parameter list of 6101 aluminum bus bar

- Mechanical Properties

- Electrical Properties

- Thermal Properties

- Flatwise Bending Radius

- Square angle busbar

- Round angle busbar

| 6101-T6 | 6101-T61 | 6101-T64 | 6101-T65 | |

| Elongation at Break | 15% | 10% | - | - |

| Elastic Modulus | 68GPa | 68GPa | 68GPa | 68GPa |

| Poissons Ratio | 0.33 | 0.33 | 0.33 | 0.33 |

| Shear Modulus | 26.0 GPa | 26.0 GPa | 26.0 GPa | 26.0 GPa |

| 6101-T6 | 6101-T61 | 6101-T64 | 6101-T65 | |

| Electrical Conductivity: Equal Volume | 57 % IACS | 59 % IACS | 60 % IACS | 58 % IACS |

| Electrical Conductivity: Equal Weight (Specific) | 190 % IACS | 200 % IACS | 200 % IACS | 190 % IACS |

| 6101-T6 | 6101-T61 | 6101-T63 | 6101-T64 | 6101-T65 | |

| CTE, linear | 21.7 µm/m-°C | 21.7 µm/m-°C | 21.7 µm/m-°C | 21.7 µm/m-°C | 21.7 µm/m-°C |

| Specific Heat Capacity | 0.895 J/g-°C | - | - | - | - |

| Thermal Conductivity | 218 W/m-K | 222 W/m-K | 218 W/m-K | 226 W/m-K | 218 W/m-K |

| Melting Point | 621 - 654 °C | 621 - 654 °C | 621 - 654 °C | 621 - 654 °C | 621 - 654 °C |

| Solidus | 621 °C | 621 °C | 621 °C | 621 °C | 621 °C |

| Liquidus | 654 °C | 654 °C | 654 °C | 654 °C | 654 °C |

| Alloy and Temper | Thickness in. | Radius min.O |

| 6101-T6 | 0.125-0.375 | 2*thickness |

| 6101-T6 | 0.125-0.375 | 2 1/2 thickness |

| 6101-T61 | 0.125-0.500 | 1*thickness |

| 6101-T61 | 0.501-0.749 | 2* thickness |

| 6101-T61 | 0.750-1.000 | 3*thickness |

| 6101-T61 | 1.001-1.625 | 4*thickness |

| 6101-T63 | 0.125-0.375 | 1 * thickness |

| 6101-T63 | 0.376-0.500 | 1 1/2 thickness |

| 6101-T63 | 0.501-1.000 | 2 1/2 thickness |

| 6101-T64 | 0.125-0.750 | 1*thickness |

| 6101-T64 | 0.751-1.000 | 2*thickness |

| 6101-T65 | 0.125-0.500 | 1*thickness |

| 6101-T65 | 0.501-0.749 | 2*thickness |

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 |

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 |