Aluminum busbars, also known as electrical-grade aluminum busbars, are a more cost-effective and efficient electrical industry conductive material compared to copper busbars. Compared to copper, aluminum busbars are lighter in weight, lower in cost, and offer better heat dissipation. Commonly used alloys include 1060, 1070, 1350, and 6101.

As a top-tier aluminum busbar supplier, Mastar Metal offers outstanding performance advantages in conductivity and current-carrying capacity. Depending on the dimensions, our busbars can withstand currents of up to 4000A. Mastar Metal customizes electrical-grade aluminum busbars to meet project requirements in accordance with ASTM B317, ASTM B236, IEC 60105, and ISO 209-1 standards.

Mastar Metal's most popular aluminum busbars

6101 EC grade Aluminum Busbar

6101 EC grade Aluminum Busbar- High mechanical strength

- Electrical conductivity of 59% IACS

- Good thermal stability

CCA EC grade Aluminum Busbar

CCA EC grade Aluminum Busbar- High electrical conductivity

- Good machinability

- Lower cost

Mastar Metal EC grade aluminum busbar product list

- 1350 Aluminum Busbar

- Conductivity of 61% IACS

- Aluminum content up to 99.5%

- Good corrosion resistance

- 1370 Aluminum Busbar

- Conductivity: 61% IACS

- High strength

- Good processability

- 1060 Aluminum Busbar

- Conductivity: 61% IACS

- Good corrosion resistance

- No cracking in 90° bends

- 1070 Aluminum Busbar

- Aluminum content: 99.7%

- Conductivity: 61% IACS

- High ductility

- 1050 Aluminum Busbar

- Conductivity: 60% IACS

- Excellent corrosion resistance

- No cracking during 90° bending

- 6063 Aluminum Busbar

- Conductivity: 59% IACS

- Good mechanical properties

- Heat treatable

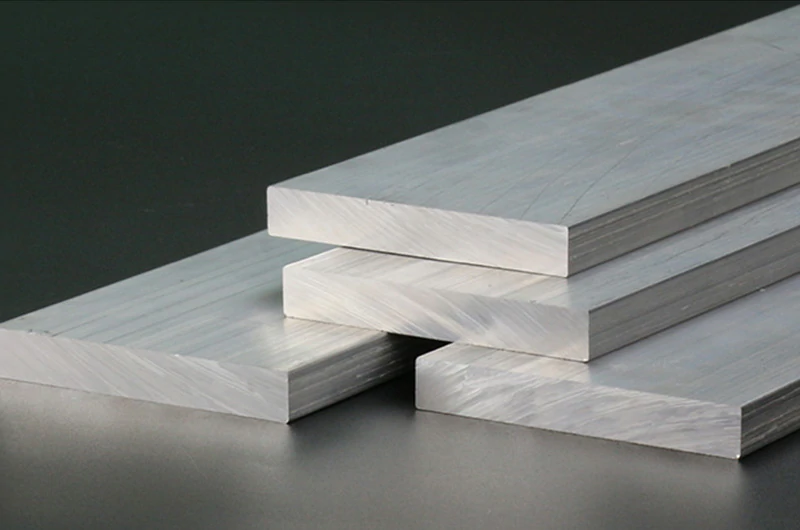

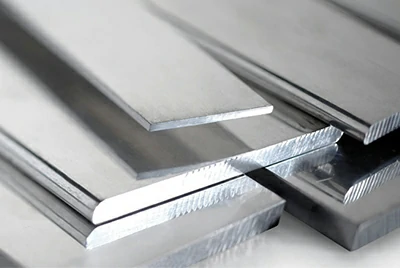

Aluminum busbar specifications

Alloys: 1050, 1060, 1070, 1100, 1350, 6063, 6101

Temper: O, T4, T5, T6, T61, T63, T64, T65

Common Sizes: 2x30mm to 20x130mm (Click to view parameter table)

Die Sizes: 3x6mm to 40x500mm (Click to view parameter table)

Length: 3m/6m/12m, customizable cutting available

Shapes: Right angle, rounded corners, R angle (no burrs on edges)

Production Methods: Extrusion, aluminum sheet sawing

Surface Requirements: Smooth surface, no impurities, no color difference, no spots, no burrs on edges, uniform and dense coating

Surface Treatment: Powder coating, anodizing, plating (tin plating/silver plating/nickel plating)

Insulation Treatment: Resin immersion, powder coating, epoxy resin coating, heat shrink tubing, PVC tubing

Quality Inspection: Dimension measurement, bending test, conductivity test, resistance test, etc.

Standards: ASTM B317, ASTM B236, IEC 60105, ISO 209-1, EN 573, EN755

Advantages of aluminum busbars

- Electrical conductivity up to 62% IACS

- High current-carrying capacity up to 4000A

- Larger surface area

- Excellent heat exchange

- More efficient heat dissipation

- Superior corrosion resistance

- No cracking on 90-degree bends

- Low density for lighter weight

- Economical, environmentally friendly, and recyclable

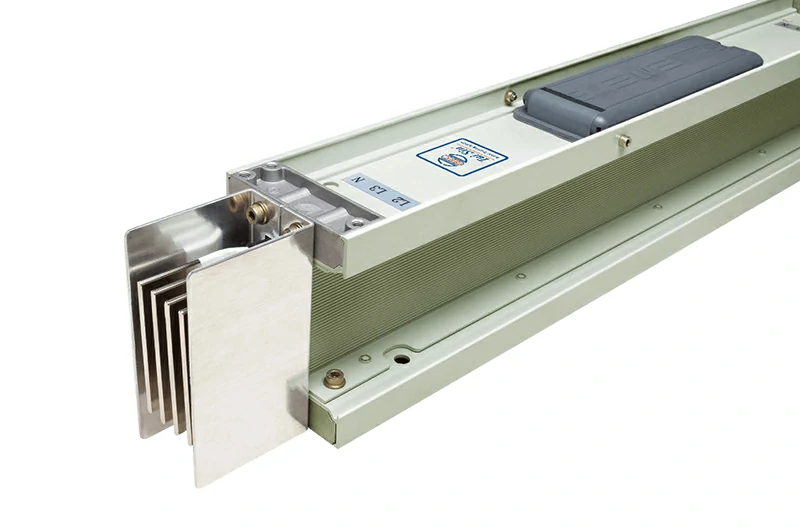

Application of aluminum busbar

- Distribution systems

- Switchgear

- Transmission lines

- Electric motors

- Transformers

- Generators

- Electrical control cabinets

- New energy power plants

- Charging stations

- Distribution/grounding systems

- Communication equipment

- Building electrical systems

Aluminum busbar vs copper busbar

- 70% lighter in weight compared to copper

- Lower transportation and installation costs

- Lower price and higher recycling rate

- Lower electrical conductivity compared to copper

- Sufficient tensile strength

- Higher current carrying capacity

- Higher price and cost

- Better connectivity

- Greater stability

- Lower resistance loss

Aluminum busbar supplier - Mastar Metal

- Mastar Metal offers aluminum busbars in various alloys such as 1070, 1350, 6101, meeting diverse requirements.

- We maintain ample stock of commonly used aluminum busbar specifications, enabling quick delivery and saving you time.

- Mastar Metal provides comprehensive mechanical machining services tailored to customer project needs, including cutting, punching, bending, and drilling.

- Our aluminum busbars feature smooth surfaces, free of burrs, impurities, or color discrepancies, with excellent straightness.

- Mastar Metal's aluminum busbars undergo electrical tests for conductivity, resistance, etc., with a maximum current capacity of up to 4000A, meeting your project requirements.

Aluminum busbar parameter table

- Alu busbar performance

- Square angle alu busbar

- Round angle alu busbar

- Alu busbar Extrusion Mold