Aluminum strip for transformer windings is a strip material made from high-purity aluminum or aluminum alloy, used for winding the transformer's winding components. The windings are one of the core components of the transformer, enabling energy conversion within the transformer.

Mastar can provide various types of aluminum strip for transformer windings, offering high conductivity and supporting multiple specifications and customization needs. We ensure strict quality control to guarantee product consistency and reliability, meeting the production requirements for various transformers.

Mastar transformer strip product details

| Alloy | 1050,1060,1070,1350 |

| Temper | O |

| Thickness | 0.3mm-2.5mm |

| Width | 20mm-1650mm |

| Specifications | EN 485 |

| Aluminum coil outer diameter | 700mm-1200mm |

| Aluminum coil inner diameter | 150mm, 305mm, 405mm, 505mm |

| Core | Paper core, or according to customer requirements. |

Common types of aluminum strip for transformers

1050 transformer strip

- Made from 1050 aluminum alloy, this transformer winding aluminum strip offers good conductivity at a low cost, meeting the minimum industry requirements for strip conductors.

Temper: O

Aluminum purity: >=99.5%

Conductivity: 61.0% IACS

Applications: Variable transformers, such as low or high voltage transformer windings.

1060 transformer strip

- Made from 1060 aluminum alloy, this aluminum strip is specifically designed for transformer windings and offers better conductivity than 1050 aluminum alloy.

Temper: O

Aluminum purity: >=99.6%

Conductivity: 61.5% IACS

Applications: Low or high voltage transformer windings, high-frequency transformers, step-up or step-down transformers.

1070 transformer strip

- 1070 aluminum strip offers excellent conductivity, suitable for complex winding designs, and can enhance the overall efficiency and performance of transformers.

Temper: O

Aluminum purity: >=99.7%

Conductivity: 62.7% IACS

Applications: High-frequency transformers, power transformers, distribution transformers.

1350 transformer strip

- 1350 aluminum strip offers excellent conductivity with good fatigue resistance and durability, providing reliable electrical performance under high-voltage conditions.

Temper: O

Aluminum purity: >=99.5%

Conductivity: 61.8% IACS

Applications: High-frequency transformers, distribution transformers, ultra-high-voltage transformers, and large power transformers.

Why use aluminum strip for transformer windings?

Lightweight: Aluminum's density is about one-third that of copper, making aluminum strip significantly reduce the overall weight of transformers. This is particularly important for large transformers, lowering transportation and installation costs.

Good conductivity: Although aluminum's conductivity is slightly lower than copper's, the conductivity of aluminum strip still meets the needs of most transformers. With proper design, electrical performance similar to copper windings can be achieved.

Cost-effective: Aluminum is much cheaper than copper, making aluminum strip a more economical choice. For large-scale transformer production, using aluminum strip can significantly reduce manufacturing costs.

Easy to process: Aluminum has good ductility and formability, making it easy to process into thin strips and complex winding shapes. This makes aluminum strip suitable for various transformer designs.

Strong corrosion resistance: Aluminum's oxide layer provides excellent corrosion resistance, making aluminum strip suitable for use in humid or corrosive environments, extending the transformer's lifespan.

Why is Mastar's aluminum strip for transformers reliable?

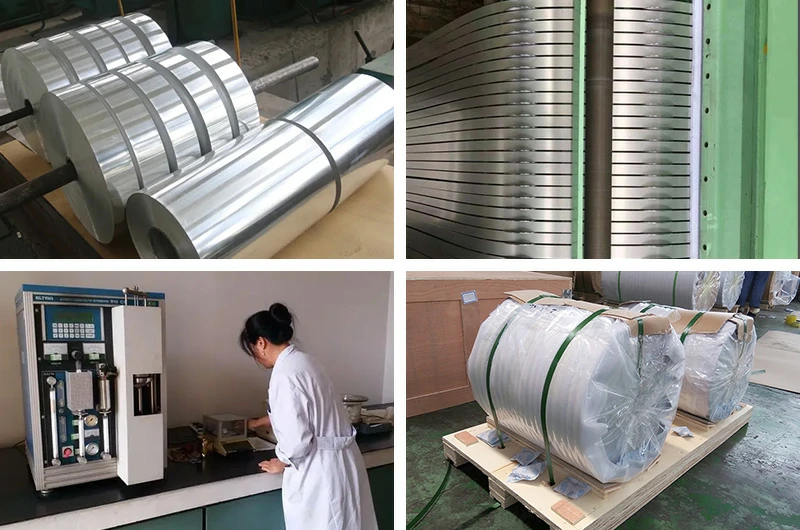

Excellent production processes

Casting and Rolling: After heating the aluminum ingot, it is continuously cast and rolled to form thicker aluminum plates.

Hot Rolling: Hot rolling further reduces the thickness of the aluminum plate, improving mechanical properties and surface quality.

Cold Rolling: Cold rolling at room temperature further processes the material to achieve the desired thickness and dimensional accuracy.

Annealing: Annealing treatment eliminates internal stresses from cold rolling, enhancing the flexibility of the aluminum strip.

Finishing: Through edge trimming, straightening, and leveling, the aluminum strip's dimensional accuracy and surface flatness are ensured.

Surface Treatment: Coating or anodizing is applied as needed to enhance corrosion resistance.

Testing: The aluminum strip is rigorously tested for thickness, width, conductivity, and other properties to ensure quality meets standards.

Standard tolerance dimensions

Mastar's transformer aluminum strip products strictly adhere to dimensional tolerance requirements. For specific data, please refer to the tolerance table below.

| Thickness | Tolerance in thickness | Tolerance in width | ||

| 20 to 300mm | Over 300 to 600mm | Over 600 to 1650mm | ||

| Over 0.2 to 0.5mm | ±0.02mm | ±0.3mm | ±0.5mm | ±1.0mm |

| Over 0.5 to 0.8mm | ±0.03mm | ±0.3mm | ±0.5mm | ±1.0mm |

| Over 0.8 to 1.3mm | ±0.04mm | ±0.3mm | ±0.5mm | ±1.0mm |

| Over 1.3 to 2.0mm | ±0.04mm | ±0.3mm | ±0.5mm | ±1.0mm |

| Over 2.0 to 3.0mm | ±0.05mm | ±0.3mm | ±0.5mm | ±1.0mm |

Performance of transformer aluminum strip

| Thickness / mm | Tensile strength / N/mm2(MPa) | Elongation / % |

| Over 0.2 to 0.5mm | 60-95MPa | 20%min. |

| Over 0.5 to 0.8mm | 60-95MPa | 25%min. |

| Over 0.8 to 1.5mm | 60-95MPa | 30%min. |

| Over 1.5 to 2.0mm | 60-95MPa | 30%min. |

| Over 2.0 to 3.0mm | 60-95MPa | 35%min. |

Surface quality requirements for transformer aluminum strip

The surface of transformer aluminum strip should be rolled, with good processing, uniform texture, and free from defects such as scratches, metal and non-metal inclusions, oil stains, and localized deformation.

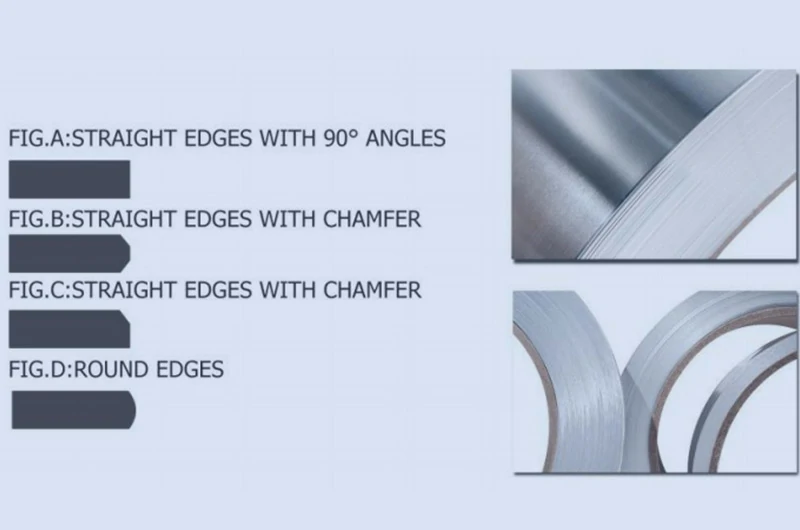

Our technical experts have conducted long-term research on this project and developed solutions for aluminum strip edge issues. Our edge treatment for aluminum strip complies with the requirements shown in the diagram.

- The transformer aluminum strip undergoes special edge treatment, resulting in smooth edges without burrs.

- The edges of the aluminum foil strip should meet the following conditions:

- Precision cut: All dimensions

- Maximum burr size: 3% of thickness or a maximum of 0.05 millimeters.

What services can Mastar provide for you?

Wide range of sizes: Mastar offers transformer aluminum strips in various alloys and specifications to meet diverse application needs.

Customization services: Mastar can provide customized aluminum strip products based on specific customer requirements, including different widths, thicknesses, and surface treatment options to ensure the material best suits the project.

Quality assurance: Products meet international standards and come with quality certification, ensuring high-quality delivery.

Fast delivery: Mastar offers professional quotations and rapid delivery services to avoid project delays.

After-sales service: Mastar provides comprehensive after-sales support to promptly address any issues encountered during the use of the products.