The copper-aluminum composite bimetallic gaskets supplied by Mastar effectively solve the transition connection problem between copper and aluminum, and fundamentally eliminate the oxidation and eutectic problems between the two metals. It not only effectively guarantees the bonding strength and bonding rate between the two metals, but also avoids the circuit breaker accident caused by the increase of contact resistance between copper and aluminum.

Mastar copper-aluminum composite gasket details

Material: Aluminum: 1100,1050,1060,1070, Copper: T2 copper

Copper: 10%-20%

Aluminum: 80%-90%

Certification:ASTM, JIS, GB, EN

Shape: round, square, rectangular

Stock sizes of Mastar copper aluminum composite gaskets

Copper-aluminum bimetallic round gasket size

The size range is as follows:

- Stock thickness: 0.8mm-4mm

- Stock diameter: 10mm-40mm

- Center control diameter: 5mm-12mm

| Thickness (mm) | Diameter (mm) | Center hole diameter (mm) | Thickness (inch) | Diameter (inch) | Center hole diameter (inch) |

| 0.8mm | 10mm | 5mm | 0.03" | 0.39" | 0.2" |

| 0.8mm | 12mm | 5.5mm | 0.03" | 0.47" | 0.22" |

| 0.8mm | 18mm | 6.5mm | 0.03" | 0.71" | 0.26" |

| 0.8mm | 22mm | 8mm | 0.03" | 0.87" | 0.31" |

| 0.8mm | 25mm | 9mm | 0.03" | 0.98" | 0.35" |

| 1mm | 10mm | 5mm | 0.04" | 0.39" | 0.2" |

| 1mm | 12mm | 5.5mm | 0.04" | 0.47" | 0.22" |

| 1mm | 18mm | 6mm | 0.04" | 0.71" | 0.24" |

| 1mm | 22mm | 8mm | 0.04" | 0.87" | 0.31" |

| 1mm | 30mm | 10mm | 0.04" | 1.18" | 0.39" |

| 1.2mm | 15mm | 6mm | 0.05" | 0.59" | 0.24" |

| 1.2mm | 18mm | 6.5mm | 0.05" | 0.71" | 0.26" |

| 1.2mm | 22mm | 8mm | 0.05" | 0.87" | 0.31" |

| 1.2mm | 25mm | 9mm | 0.05" | 0.98" | 0.35" |

| 1.2mm | 28mm | 10mm | 0.05" | 1.1" | 0.39" |

| 1.5mm | 10mm | 5mm | 0.06" | 0.39" | 0.2" |

| 1.5mm | 12mm | 5.5mm | 0.06" | 0.47" | 0.22" |

| 1.5mm | 18mm | 6mm | 0.06" | 0.71" | 0.24" |

| 1.5mm | 22mm | 8mm | 0.06" | 0.87" | 0.31" |

| 1.5mm | 30mm | 10mm | 0.06" | 1.18" | 0.39" |

| 2mm | 12mm | 5mm | 0.08" | 0.47" | 0.2" |

| 2mm | 15mm | 6mm | 0.08" | 0.59" | 0.24" |

| 2mm | 18mm | 6.5mm | 0.08" | 0.71" | 0.26" |

| 2mm | 22mm | 8mm | 0.08" | 0.87" | 0.31" |

| 2mm | 28mm | 9mm | 0.08" | 1.1" | 0.35" |

| 2.5mm | 10mm | 5mm | 0.1" | 0.39" | 0.2" |

| 2.5mm | 12mm | 5.5mm | 0.1" | 0.47" | 0.22" |

| 2.5mm | 15mm | 6mm | 0.1" | 0.59" | 0.24" |

| 2.5mm | 18mm | 6.5mm | 0.1" | 0.71" | 0.26" |

| 2.5mm | 25mm | 9mm | 0.1" | 0.98" | 0.35" |

| 3mm | 15mm | 6mm | 0.12" | 0.59" | 0.24" |

| 3mm | 18mm | 6.5mm | 0.12" | 0.71" | 0.26" |

| 3mm | 22mm | 8mm | 0.12" | 0.87" | 0.31" |

| 3mm | 30mm | 10mm | 0.12" | 1.18" | 0.39" |

| 3mm | 35mm | 11mm | 0.12" | 1.38" | 0.43" |

Copper Aluminum Composite Shims Stock Sizes (Rectangular and Square Shims)

| Thickness(mm) | Width(mm) | Height(mm) | Thickness(inch) | Width(inch) | Height(inch) |

| 1mm | 30mm | 30mm | 0.04" | 1.18" | 1.18" |

| 1mm | 35mm | 35mm | 0.04" | 1.38" | 1.38" |

| 1mm | 35mm | 40mm | 0.04" | 1.38" | 1.57" |

| 1mm | 40mm | 40mm | 0.04" | 1.57" | 1.57" |

| 1mm | 50mm | 50mm | 0.04" | 1.97" | 1.97" |

| 1mm | 60mm | 60mm | 0.04" | 2.36" | 2.36" |

| 1mm | 80mm | 80mm | 0.04" | 3.15" | 3.15" |

| 1mm | 100mm | 100mm | 0.04" | 3.94" | 3.94" |

| 1mm | 120mm | 120mm | 0.04" | 4.72" | 4.72" |

| 1mm | 125mm | 125mm | 0.04" | 4.92" | 4.92" |

| 1mm | 100mm | 150mm | 0.04" | 3.94" | 5.91" |

| 1mm | 150mm | 150mm | 0.04" | 5.91" | 5.91" |

| 1mm | 200mm | 200mm | 0.04" | 7.87" | 7.87" |

| 2mm | 30mm | 30mm | 0.08" | 1.18" | 1.18" |

| 2mm | 35mm | 35mm | 0.08" | 1.38" | 1.38" |

| 2mm | 40mm | 40mm | 0.08" | 1.57" | 1.57" |

| 2mm | 50mm | 50mm | 0.08" | 1.97" | 1.97" |

| 2mm | 60mm | 60mm | 0.08" | 2.36" | 2.36" |

| 2mm | 80mm | 80mm | 0.08" | 3.15" | 3.15" |

| 2mm | 100mm | 100mm | 0.08" | 3.94" | 3.94" |

| 2mm | 120mm | 120mm | 0.08" | 4.72" | 4.72" |

| 2mm | 150mm | 150mm | 0.08" | 5.91" | 5.91" |

| 2mm | 200mm | 200mm | 0.08" | 7.87" | 7.87" |

The above table shows the common sizes in Mastar's inventory. If you can't find the size that suits you, please contact us in time. Mastar's huge inventory will help you solve it.

Mastar copper-aluminum composite gasket performance

| Adhesion strength | ≥12 N/mm |

| Tensile strength | 90-150MPa |

| Elongation | 15%-35% |

| DC resistivity | < 0.0245 Ω.mm2/m |

Why use Mastar's Copper Aluminum Bimetallic Gaskets?

Avoid electrochemical corrosion

When copper and aluminum are in direct contact, electrochemical corrosion will occur due to potential differences, leading to rapid oxidation and loss of aluminum. Copper-aluminum composite gaskets use intermediate transition materials to isolate the two metals, significantly reducing the risk of corrosion.

Reduce contact resistance

The direct connection of copper and aluminum is prone to produce an oxide layer due to corrosion, which increases the contact resistance and leads to increased power loss. The use of copper-aluminum composite gaskets can ensure stable conductive performance, reduce contact resistance, and improve circuit reliability.

Avoid local heating

Increased contact resistance will cause local heating of the circuit, which may lead to fire or other electrical accidents. Copper-aluminum composite gaskets effectively avoid local heating problems by optimizing electrical conductivity and reducing heat loss.

Improve mechanical connection strength

Copper-aluminum composite gaskets are produced using advanced technology. The two metals have high bonding strength and can provide good mechanical properties to ensure long-term stability of the connection.

Extend equipment life

By avoiding electrochemical corrosion and local heating problems, the service life of electrical equipment is extended, maintenance and replacement costs are reduced, and economic benefits are improved.

Suitable for various industrial scenarios

Copper-aluminum composite gaskets are suitable for various scenarios that require copper-aluminum transition connections in the power, electronics and machinery industries, and can widely meet practical application needs.

Application of Mastar's copper-aluminum composite gaskets

Transformer connection parts

The conductive parts of the transformer usually involve transition connections between copper and aluminum materials. Copper-aluminum composite gaskets can be used at the wiring terminals of the transformer to reduce contact resistance, ensure efficient current transmission, and avoid electrical failures caused by corrosion.

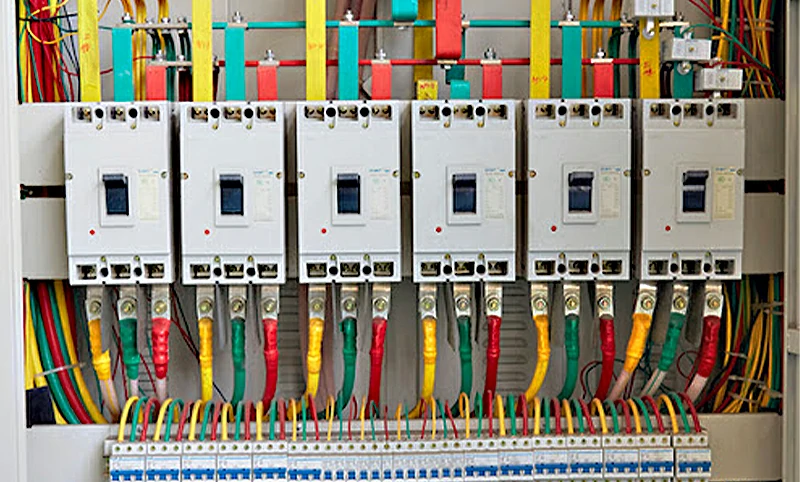

Switchgear and busbar connection

In switchgear and distribution cabinets, copper and aluminum busbars often need to be connected. As a high-quality transition material, copper-aluminum composite gaskets not only improve the mechanical strength of the connection, but also effectively reduce the incidence of electrical accidents and extend the service life of the equipment.

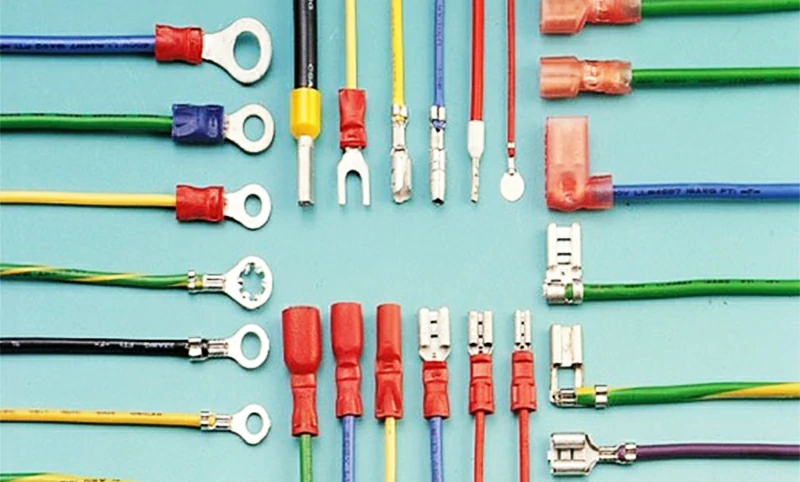

Power equipment installation and maintenance

In the installation and maintenance of power equipment, copper-aluminum composite gaskets are widely used in cable terminals, junction boxes and grounding systems to ensure safe connections between different materials, while simplifying the maintenance process and reducing maintenance costs.

Photovoltaic power stations and wind farms

In photovoltaic power stations and wind farms, there is a high demand for the connection of copper and aluminum terminals. Copper-aluminum composite gaskets can effectively solve the problem of decreased conductivity caused by electrochemical corrosion in harsh environments, and ensure the stability and efficiency of new energy power generation systems.

Electric vehicle charging station equipment

In electric vehicle charging stations, charging modules and their electrical equipment often require copper-aluminum conductor transition connections. Copper-aluminum composite gaskets can provide stable electrical connections, reduce energy loss, and extend the service life of equipment, especially for high-power fast charging equipment.

Smart grid components

In smart grid systems, copper-aluminum composite gaskets are used to connect various interconnected components, such as smart circuit breakers, power metering devices, and distributed power devices, to ensure compatibility and safety between multi-material equipment.

Energy storage system conductor connection

Energy storage systems are widely used in power regulation and backup power scenarios. Copper-aluminum composite gaskets play a key role in their conductive connections, avoiding efficiency losses between battery modules and external conductors due to material incompatibility.

What services can Mastar provide for you?

Free Sample Support

Mastar provides customers with free sample services to help customers quickly verify the performance of products, such as conductivity, corrosion resistance and bonding strength. This service not only reduces customers' trial costs, but also shortens the purchase decision cycle, allowing customers to choose copper-aluminum composite gaskets that suit their application needs more quickly.

Surface treatment service

Mastar provides a variety of surface treatment processes, including anti-corrosion coating, electroplating, oxidation treatment, etc., to enhance the durability of copper-aluminum composite gaskets in harsh environments. At the same time, we can perform surface polishing and sandblasting to optimize the finish and aesthetics of the gaskets, and can also customize the logo according to customer needs to improve the recognition and traceability of the products.

Deep processing service

Mastar provides precise deep processing services, including cutting, punching, bending and forming, to meet the special requirements of complex application scenarios for product size, shape and structure. We can adjust the thickness and edge design of the gasket to ensure that the product is fully compatible with the customer's power equipment and installation requirements.

Personalized customization service

Mastar supports personalized customization of various non-standard sizes, specifications and performances to tailor the most suitable solutions for customers. Whether it is to enhance conductivity, improve mechanical strength, or adapt to special environmental requirements, we can provide customized copper-aluminum composite gaskets to meet diverse application needs.

Comprehensive technical support

Mastar provides one-stop technical support from selection consultation to installation guidance to help customers solve technical problems and improve product efficiency. Our after-sales service system is complete and can quickly respond to customer questions, ensuring the best performance of copper-aluminum composite gaskets in actual applications, and providing customers with a worry-free experience throughout the process.