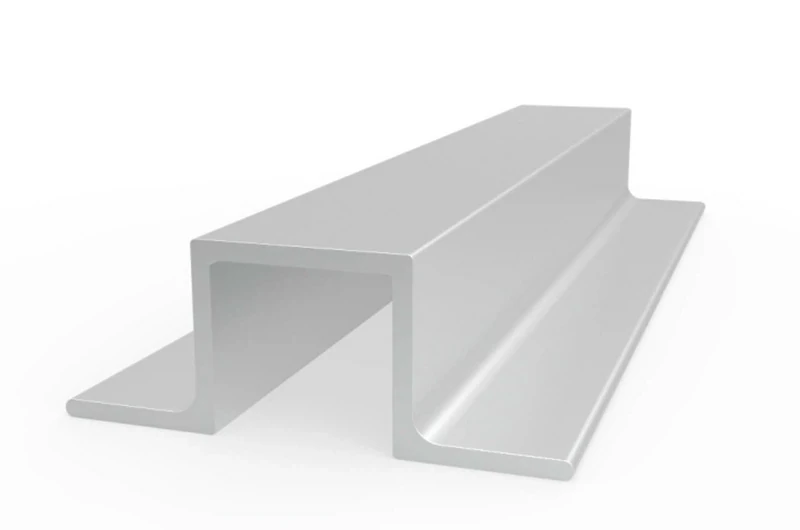

Aluminum H Channel possesses advantages such as lightweight, high strength, corrosion resistance, easy processing, and surface treatment. It is aesthetically pleasing and contributes to improved production efficiency.

Therefore, it has been widely used in the fields of construction, transportation, industrial manufacturing, and decoration, becoming an indispensable material in various industries.

Why choose Mastar-Metal as your aluminum supplier

- Competitive prices

- Diverse sizes with minimal tolerances, offering customized cutting services

- High flatness and straightness

- Fast and on-time delivery

- Detailed transportation and tax information

Specifications of Aluminum H Channel

Alloys: 6060, 6061, 6063, 7075

Temper: T5, T6, T66

Length: 3m-6m (customizable cutting available)

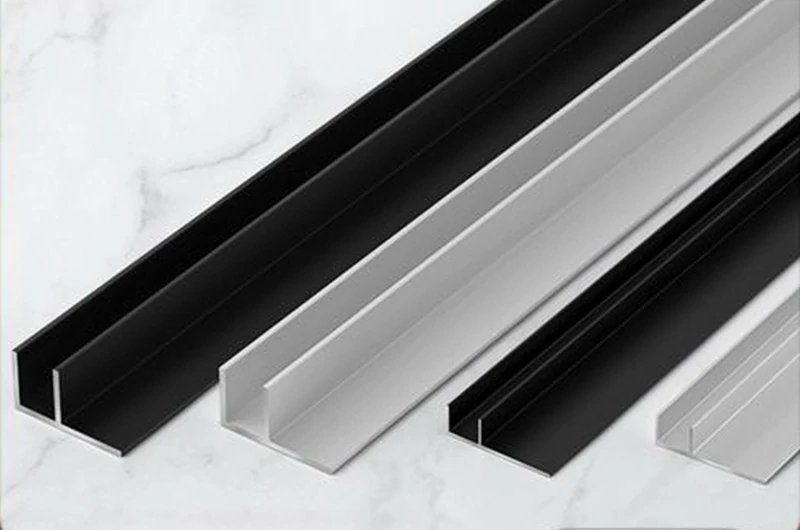

Surface treatments: Powder coating, anodizing, electrophoresis, wood grain finish, PVDF coating, polishing, brushing

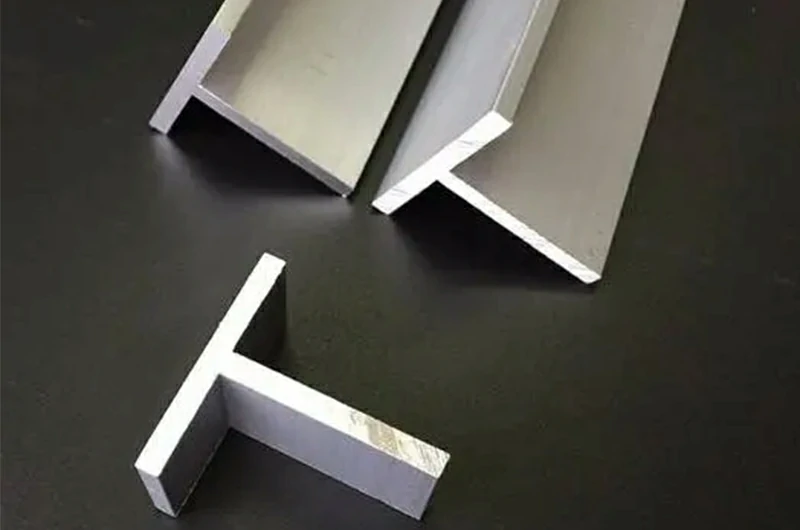

Deep processing capabilities: CNC machining, drilling, milling, precision cutting, stamping, welding, bending, assembly

Standards: EN 755-1/9, EN 13249, ASTM B221, JIS H4006, GOST 21428

Certifications: SGS, ROHS, ISO, CE

Packaging options: Wooden box packaging, cardboard packaging, shrink film packaging, and pallet packaging (or as per customer requirements).

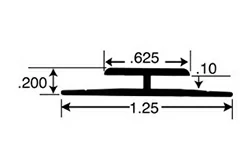

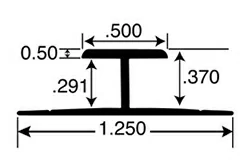

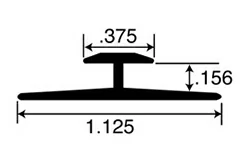

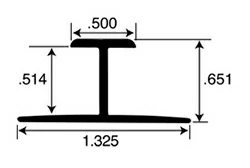

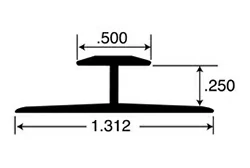

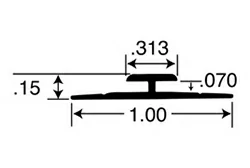

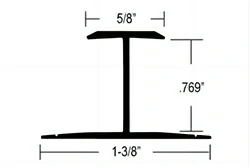

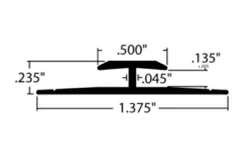

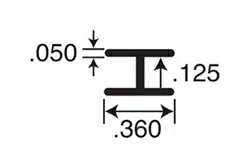

Popular sizes of aluminum H channel

Irregular sizes

We also have professional personnel who can customize H-shaped aluminum profiles based on your requirements. Quick Quote

- 3/32″ Anodized Aluminum H Channel

- 1/4″ Anodized Aluminum H Channel

- 5/32″ Anodized Aluminum H Channel

- 1/2″ Anodized Aluminum H Channel

- 1/4″ Anodized Aluminum H Channel

- 1/16″ Anodized Aluminum H Channel

- 3/4″ Aluminum H Channel

- 1/8″ Aluminum H Channel

- 0.125″ Aluminum H Channel

Standard sizes

| Specification | A (mm) | B (mm) | C (mm) | D (mm) |

| Aluminium H Channel Sizes | 5 | 6 | 1 | 1 |

| Aluminium H Channel Sizes | 6 | 9.6 | 1.25 | 1.5 |

| Aluminium H Channel Sizes | 6 | 10.1 | 1.25 | 3 |

| Aluminium H Channel Sizes | 7.2 | 10.75 | 3 | 3.5 |

| Aluminium H Channel Sizes | 9.5 | 2.4 | 0.8 | 3.5 |

| Aluminium H Channel Sizes | 10 | 4 | 1 | 1 |

| Aluminium H Channel Sizes | 10 | 10.1 | 1.25 | 3 |

| Aluminium H Channel Sizes | 12 | 6 | 2 | 2 |

| Aluminium H Channel Sizes | 13 | 8 | 2 | 2 |

| Aluminium H Channel Sizes | 19 | 18 | 6 | 8 |

| Aluminium H Channel Sizes | 24 | 38.5 | 4 | 4 |

| Aluminium H Channel Sizes | 25 | 13 | 2 | 2 |

| Aluminium H Channel Sizes | 30 | 15 | 3 | 3 |

| Aluminium H Channel Sizes | 31 | 26.1 | 3 | 3 |

| Aluminium H Channel Sizes | 34 | 31 | 2 | 2 |

| Aluminium H Channel Sizes | 34 | 27.4 | 2.3 | 2.3 |

| Aluminium H Channel Sizes | 35 | 30.4 | 2.3 | 2.3 |

| Aluminium H Channel Sizes | 44 | 25 | 2 | 2 |

| Aluminium H Channel Sizes | 50 | 31.4 | 3 | 3 |

| Aluminium H Channel Sizes | 50 | 28.65 | 1.5 | 1.5 |

| Aluminium H Channel Sizes | 50 | 35 | 1.5 | 3 |

| Aluminium H Channel Sizes | 50 | 35 | 2 | 2 |

| Aluminium H Channel Sizes | 50.8 | 16.96 | 1.63 | 2.54 |

Applications of aluminum H channel

- H channels are widely used in building components such as beams, columns, trusses, and roof supports, providing strong structural support for constructions.

- Leveraging its advantages in easy processing and surface treatment, H channels have become an ideal choice for home decor, commercial display racks, and interior design.

- H channels are extensively used in mechanical equipment for components like machine tool beds, frames, and brackets.

- They are also widely applied in transportation vehicles like automobiles, trains, and ships for frame and body components.

- Furthermore, H channels find extensive applications in furniture manufacturing, electrical equipment, glass frames, solar panel supports, and other fields, showcasing their versatile potential.

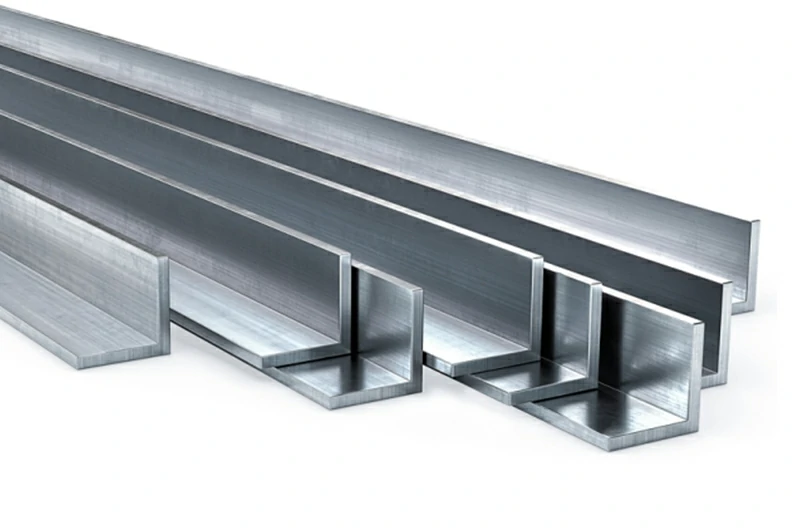

Advantages of aluminum H channel

- Excellent load-bearing capacity, bending resistance, and torsional resistance, able to withstand significant loads.

- Can be processed into shape using various methods like extrusion, welding, and joining, resulting in high production efficiency and low cost.

- Compared to traditional steel I-beams, aluminum H channels are lighter in weight yet still offer excellent performance.

- Suitable for harsh environments such as moisture, acid, and alkali, widely used in outdoor constructions and components.

- Surface treatment options like anodizing and coating allow for a variety of colors and textures.

- Aluminum profiles are recyclable, reducing resource waste.