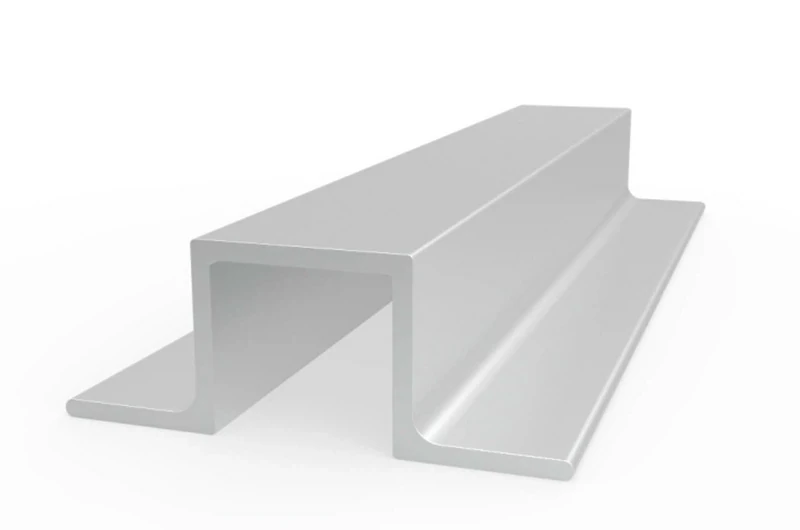

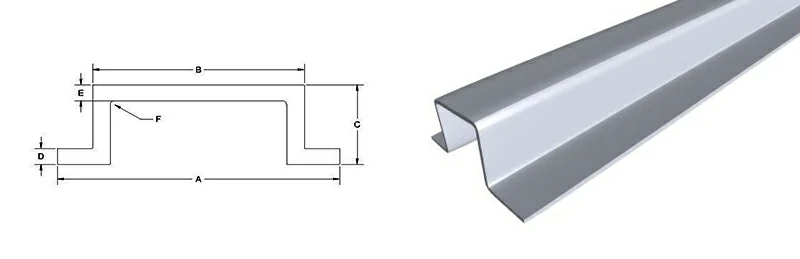

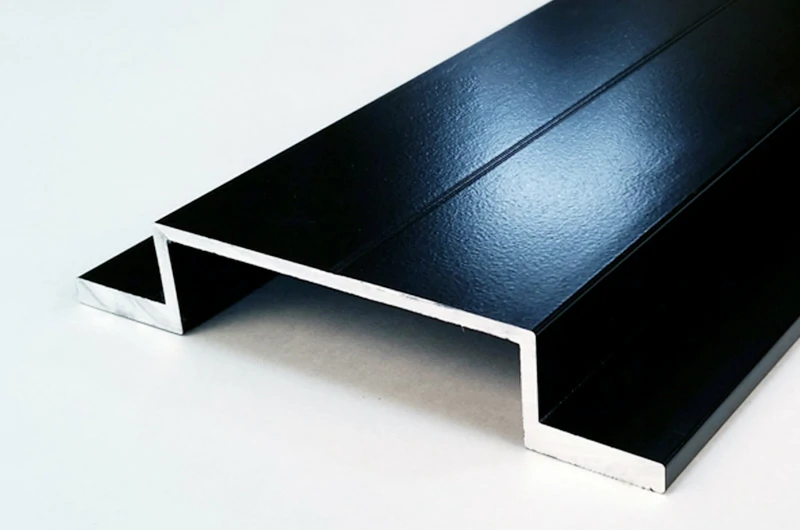

Aluminum hat channel, with a cross-section similar to a "hat," is sometimes referred to as omega-sections or sub-girts. Its unique structure includes two horizontally outward flared edges (the brim) and two vertical sides (the sides of the hat), with a flat horizontal surface on top.

The distinctive geometric design makes it an ideal solution for wall leveling. Its grooved metal components are effective for smoothing walls, ensuring stability and aesthetic appeal. Due to its typical applications, it is also known as an aluminum furring channel.

Specification of aluminum hat channel

Alloys: 6060,6061,6063,2024,7075

Temper: t5, t6

Width: 50-200mm

Tall: 12-50mm

Wall: 1.5-6mm

Length: up to 6m (customizable cutting available)

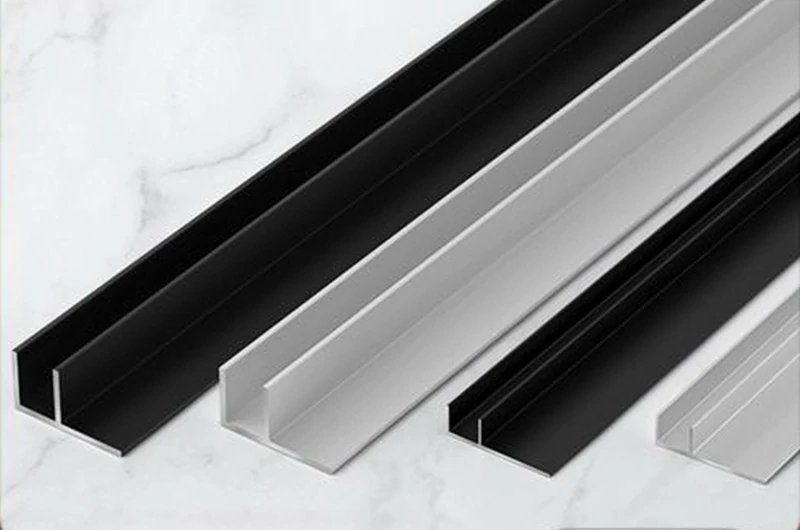

Colors: white, black, bronze, brushed, brite gold, gray

Surface treatments: mill finish (mf), polishing, powder coating, anodizing, PVDF painting

Color: clear anodized, bronze anodized, black anodized, gold anodized

Deep processing: CNC machining, drilling, milling, precision cutting, welding, bending

Standards: ASTM-B221, EN754, EN 755

Certificate: iso9001, SGS

Mastar's aluminum hat channel hot sale size chart

Aluminum hat channel

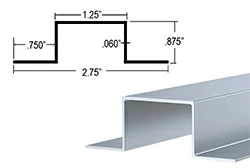

- 2-3/4″x 7/8″tall x .06″ wall aluminum hat channel

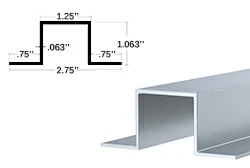

- 2-3/4″x 1.063″tall x .063″ wall aluminum hat channel

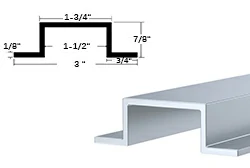

- 3″x 7/8″tall x 1/8″wall aluminum hat channel

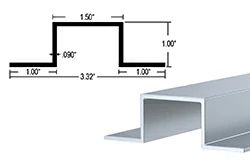

- 3.32″ x 1″tall x 0.09″wall aluminum hat channel

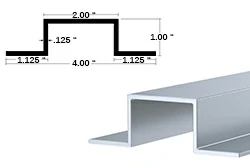

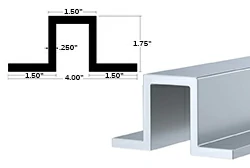

- 4.00″ x 1.00″ tall x .125″ wall aluminum hat channel

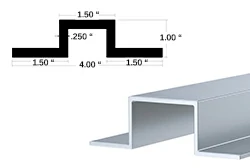

- 4.00″ x 1.00″ tall x .25″ wall aluminum hat channel

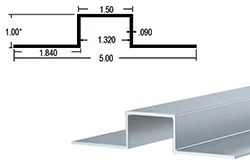

- 5″ x 1″ tall x 0.09″wall aluminum hat channel

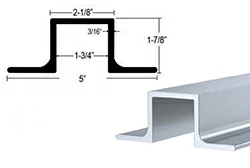

- 5″ x 1-7/8″ tall x 3/16″wall aluminum hat channel

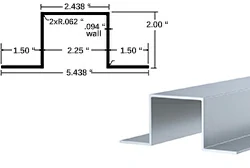

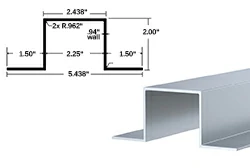

- 5.438″ x 2″ tall x 0.094″wall aluminum hat channel

Custom aluminum hat channel

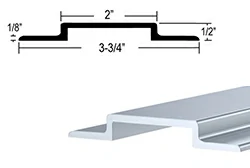

- 3-3/4″ x 1/2″ tall x 1/8″wall aluminum hat channel

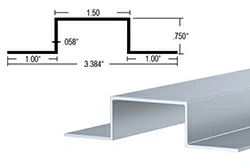

- 3-3/8″ x 3/4″ tall x 0.58″wall aluminum hat channel

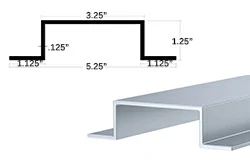

- 5-1/4″ x 1-1/4″ tall x 1/8″wall aluminum hat channel

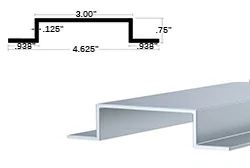

- 4-5/8″ x 3/4″ tall x 1/8″wall aluminum hat channel

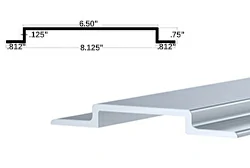

- 8-1/8″ x 3/4″ tall x 1/8″wall aluminum hat channel

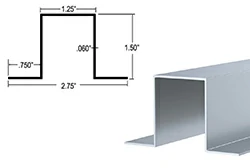

- 2-3/4″ x 1-1/2″ tall x 0.06″wall aluminum hat channel

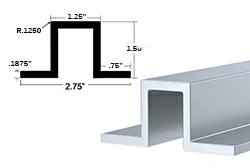

- 2-3/4″ x 1-1/2″ tall x 3/16″wall aluminum hat channel

- 4″ x 1-3/4″ tall x 1/4″wall aluminum hat channel

- 5.438″ x 2″ tall x 0.94″wall aluminum hat channel

The above are special-sized aluminum hat channels. If you have specific project requirements, you can send us your drawings. We will create custom molds to meet your needs and manufacture aluminum hat channels tailored to your specifications. Quick Quote

Mastar's aluminum j channel size chart

| A/in | B/in | C/in | D/in | E/in | R/in | Wt/ft |

| 1 | 0.5 | 0.625 | - | 0.062 | 0.149 | |

| 1.06 | 0.62 | 0.165 | 0.04 | 0.06 | 0.015 | 0.061 |

| 1.25 | 0.5 | 0.2 | - | 0.05 | 0.087 | |

| 1.325 | 0.831 | 0.625 | 0.135 | 0.109 | 0.016 | 0.298 |

| 1.75 | 0.75 | 0.752 | 0.14 | 0.07 | 0.329 | |

| 1.76 | 1 | 1.02 | - | 0.09 | 0.391 | |

| 1.76 | 0.76 | 0.97 | 0.15 | 0.15 | 0.42 | |

| 2.0005 | 0.8765 | 0.875 | - | 0.032 | 0.0625 | 0.134 |

| 2.002 | 0.876 | 1 | - | 0.032 | 0.062 | 0.144 |

| 2.05 | 1 | 0.4 | - | 0.125 | 0.33 | |

| 2.126 | 1.126 | 0.38 | - | 0.063 | 0.199 | |

| 2.24 | 0.88 | 1 | - | 0.12 | 0.03 | 0.542 |

| 2.266 | 0.5 | 0.687 | 0.051 | 0.072 | 0.187 | 0.204 |

| 2.374 | 1 | 0.75 | - | 0.08 | 0.187 | 0.351 |

| 2.5 | 1 | 1 | 0.093 | 0.093 | 0.093 | 0.48 |

| 2.5 | 1 | 1.25 | 0.109 | 0.078 | 0.093 | 0.438 |

| 2.535 | 1.655 | 0.396 | 0.05 | 0.05 | 0.016 | 0.23 |

| 2.938 | 1.5 | 0.875 | - | 0.094 | 0.094 | 0.491 |

| 3 | 1.25 | 1 | 0.125 | 0.125 | 0.062 | 0.775 |

| 3 | 1.25 | 1 | 0.075 | 0.14 | 0.07 | 0.506 |

| 3 | 1.5 | 1.25 | 0.125 | 0.125 | 0.062 | 0.787 |

| 3 | 1.5 | 0.57 | - | 0.05 | 0.236 | |

| 3.004 | 1.75 | 0.35 | - | 0.05 | 0.117 | |

| 3.25 | 1.876 | 0.375 | 0.063 | 0.063 | 0.015 | 0.29 |

| 3.626 | 2 | 1.25 | 0.1 | 0.09 | 0.094 | 0.66 |

| 4.5 | 2.5 | 1.875 | 0.25 | 0.25 | 0.015 | 2.326 |

| 5 | 1.375 | 1.5 | 0.094 | 0.094 | 0.187 | 0.766 |

| 5 | 2.75 | 0.93 | 0.12 | 0.18 | 0.031 | 1.18 |

| 5.5 | 3 | 1.25 | 0.125 | 0.125 | 0.125 | 1.098 |

Best applications for aluminum hat channel

Aluminum hat channels have a wide range of applications in the construction and engineering fields. Here are their main application areas and advantages:

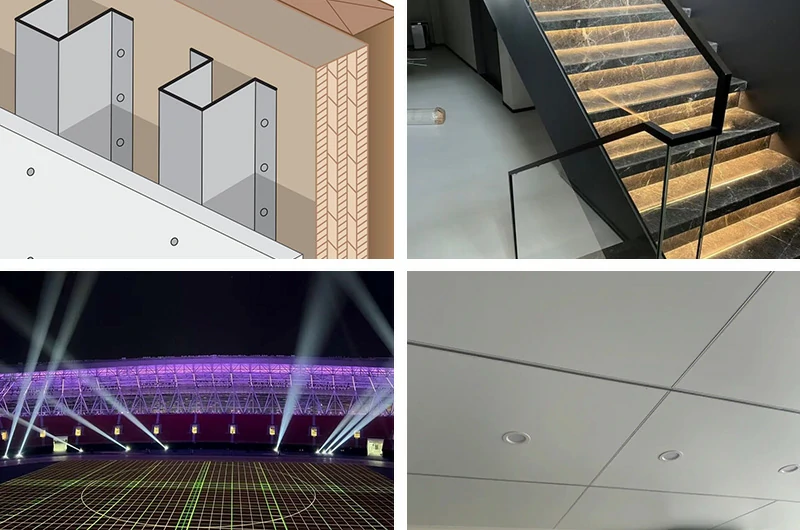

Brick walls and ceiling components: the 90° hat channel is used to create a gap between brick walls and ceiling components, connecting wall panels and ensuring smooth, even surfaces.

Roof and wall support: hat purlins provide sturdy support for lightweight steel structure roofs and walls, offering a strong structural framework.

Metal roof renovation: used as retrofit supports, they enhance structural strength when installing new panels on existing metal roofs.

Lap installation: aluminum hat channels can be used for lap installation, making them ideal for various stage designs and other structural applications.

Glass fixation: long hat channels are suitable for securing glass, ensuring stable and aesthetically pleasing installations.

Features of aluminum hat channel

Durability: highly durable and scratch-resistant, maintaining excellent performance and appearance over long-term use.

Impact resistance: aluminum has high strength and impact resistance, capable of withstanding significant loads and external forces.

Corrosion resistance: when exposed to air, aluminum forms an oxide layer that enhances its corrosion resistance, making it suitable for humid environments.

Aesthetic appeal: can be enhanced through anodizing, powder coating, and other surface treatments to meet various aesthetic needs.

Easy to process and install: aluminum is easy to cut, drill, weld, and shape, simplifying installation and reducing labor costs.

Cost-effective: although the initial cost is higher, its durability and long lifespan make it a cost-effective choice in the long run.

Eco-friendly and recyclable: aluminum is highly recyclable, aligning with sustainable development and environmental protection goals.

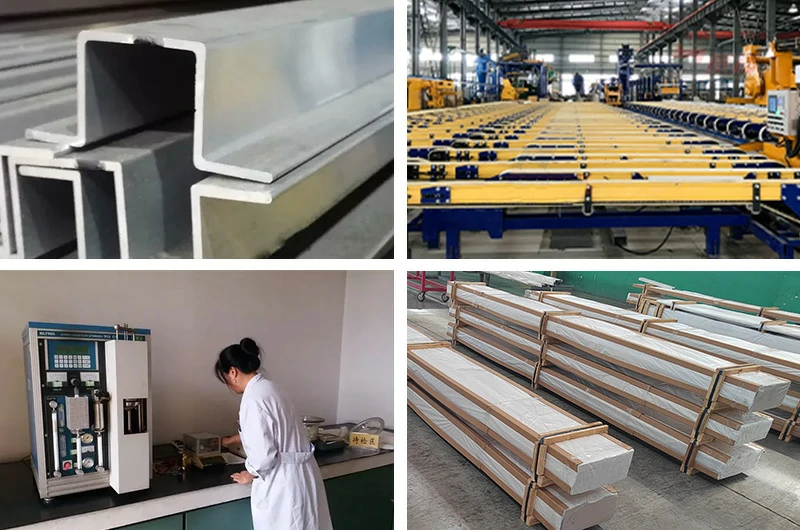

Mastar——your one-stop aluminum profile supplier

One-stop procurement: we offer comprehensive services, from profile design and customization to processing, surface treatment, and sea freight delivery, allowing you to complete your project with ease.

Extensive product selection: our wide range of aluminum profiles includes various standard and custom profiles, with a full set of molds to meet diverse project requirements.

Customized solutions: our design team can tailor solutions to your specific needs and environment, ensuring you get the best design and functionality.

Diverse surface treatments: we provide multiple surface treatment options, including brushed finish, polished finish, anodizing, powder coating, and PVDF painting, giving you more choices.

Secondary processing advantages: Mastar offers free profile cutting services to ensure the profiles meet your length requirements. We also provide drilling, milling, and bending services.

Pre-shipment inspection: Mastar strictly adheres to quality control standards, ensuring every batch of aluminum profiles undergoes thorough inspection and testing before shipment. This guarantees you can purchase our products with confidence, ensuring smooth project execution.

Premium after-sales service: we prioritize customer satisfaction, offering prompt responses and attentive after-sales service, allowing you to confidently choose and use our products.

Bulk purchase price advantage: with our robust supply chain and production system, we can offer competitive prices, enabling you to achieve greater economic benefits in bulk purchases.

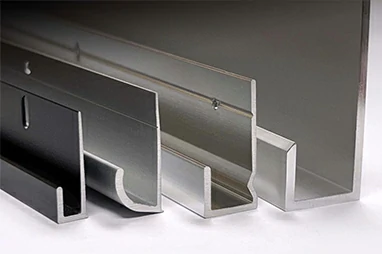

Aluminum vs. Galvanized steel vs. Stainless steel hat channel

Aluminum, galvanized steel, and stainless steel hat channels each have their own advantages in different applications and environments. Below is a detailed comparison of these three materials, including durability, applications, ease of installation, cost, and aesthetics.

| Feature | Aluminum hat channel | Galvanized steel hat channel | Stainless steel hat channel |

| Durability | Excellent corrosion resistance, lightweight, high strength | High durability, corrosion and fire- resistant | Superior corrosion resistance and high strength |

| Aesthetics | Attractive, can be anodized or coated | Plain appearance, suitable for hidden installations | Elegant, suitable for high-visibility applications |

| Ease of installation | Easy to process and install | Simple installation, enhances load-bearing capacity | Slightly more complex installation |

| Cost | Moderate | Economical, high cost- effectiveness | Higher cost |

| Applications | Air gaps in interior and exterior walls, decorative uses | Heavy-duty support for ceilings and walls | Heavy construction and exposed structures |

Aluminum hat channel

Aluminum hat channels are widely used in various construction and decorative applications due to their lightweight, corrosion resistance, and versatility.

- Lightweight: aluminum has a lower density, making it lighter than galvanized steel or stainless steel of the same volume, which facilitates easier installation and transportation.

- Corrosion resistance: the natural oxide layer provides good corrosion resistance, making it suitable for humid environments, though not as corrosion-resistant as stainless steel.

- Good workability: aluminum is easy to cut, bend, and shape, simplifying installation and meeting customized requirements.

- Aesthetics: can be anodized or powder-coated to provide a variety of attractive finishes, making it suitable for decorative applications and exposed installations.

- Applications: used for air gaps between interior and exterior walls, exterior cladding, curtain walls, and rainscreen installations.

- Cost: typically cheaper than stainless steel but more expensive than galvanized steel.

Galvanized steel hat channel

Galvanized steel hat channels are favored by builders for their superior fire resistance and soundproofing capabilities, making them ideal for structural support.

- Corrosion protection: the zinc coating on the surface effectively prevents rust, making it suitable for outdoor or less corrosive indoor environments.

- High strength: steel has higher hardness and strength than aluminum, suitable for applications requiring higher load-bearing capacity.

- Ease of installation: simple installation that enhances load-bearing capacity, ideal for heavy-duty basement construction.

- Applications: plain appearance, suitable for hidden installations, commonly used on ceilings or walls to provide strong support.

- Cost: lower cost compared to stainless steel, especially in environments that do not require extreme corrosion resistance.

Stainless steel hat channel

- Stainless steel hat channels are ideal for demanding environments due to their superior

- Durability: with high strength and corrosion resistance, stainless steel hat channels have a long service life and low maintenance costs.

- Superior corrosion resistance: common grades like 304 and 316 offer excellent corrosion resistance, making them suitable for marine or high-humidity environments.

- Hygienic: stainless steel is the preferred material in industries requiring high cleanliness, such as food processing and medical facilities.

- Applications: with an elegant appearance, they are suitable for high-visibility exposed structural applications, heavy construction, and industrial fields.

- Cost: generally more expensive than aluminum and galvanized steel, but potentially more cost-effective over the long term due to low maintenance needs.

Each type of hat channel material has its unique advantages and suitable applications. The choice of the appropriate material should be based on the specific project requirements and budget. Quick Quote

Faqs

1.why use aluminum hat channel for brick walls and ceiling components?

Aluminum hat channel provides proper alignment and spacing of materials, ensuring that wall panels and tiles are placed evenly and straight. Its lightweight, corrosion resistance, high strength, and ease of processing make installation convenient, durable, and aesthetically pleasing, suitable for various construction and decoration needs.

2.What should individual buyers consider when purchasing aluminum hat channel?

- Determine required area: measure the total area to be covered to ensure you purchase enough material.

- Size measurement: accurately measure the length, width, and height of the installation area; Mastar can provide cutting services.

- Choose specifications: different sizes are suitable for different applications; multiple finishes and colors are available to match the actual project.

- Preparation before installation: ensure walls/ceilings are clean and flat, and have power tools and fasteners (self-tapping screws/nails) ready.

- Installation process: use fasteners to vertically install the aluminum hat channel onto the wall/ceiling, connecting wall panels/ceilings or other decorative materials.

- Safety considerations: wear gloves, safety glasses, and other protective gear, and use stable ladders or scaffolding.

3.What should distributors consider when purchasing aluminum hat channel?

- Order quantity: determine a reasonable purchase volume based on downstream market conditions to meet customer demand and optimize inventory management.

- Price discounts: Mastar offers discounts for bulk purchases, ensuring customers get the best price.

- Confidentiality agreements: Mastar can sign confidentiality agreements upon request to protect both parties business secrets and purchase details.

- Professional advice: recommend specifications and models based on popular market products or actual end-use applications to meet customer needs.

- After-sales service: provide excellent after-sales service, including returns, exchanges, and technical support.

4. What should wholesalers/retailers consider when purchasing aluminum hat channel?

- Low minimum order quantity: support for small batch orders for retailers, allowing flexible order adjustments to suit market demand.

- Wide variety: choose from various specifications, models, and finishes to meet different customer needs.

- Rich finishes: focus on new styles and multi-color/finish products to attract more customers and enhance competitiveness.

- Inventory management: regularly organize inventory to keep products orderly and easy to manage.