Aluminum heat sink profile specifications

Alloys: 6061, 6063, 6005

Length: 10-6000 mm (customizable for large heat sinks)

Width: 10-500 mm

Common Types: Plate fin type, pin fin type

Common Processes: Extrusion, fin bonding, turning, forging, die-casting

Surface Finish: Anodizing, polishing, electroplating, painting, laser marking, Alodine 5200, Acculabs 628

Colors: Black, silver, blue, red

Processing: CNC machining, cutting, punching, bending, welding, milling, CNC control

Standards: EN 442, ASTM E2112, NAS4122, NAS4121

Certifications: RoHS, CE, SGS, ISO, TUV SUD, UL

Classification of standard aluminum heat sink

Mastar Metal has an extensive stock of standard aluminum radiator profiles in a wide range of sizes and molds.

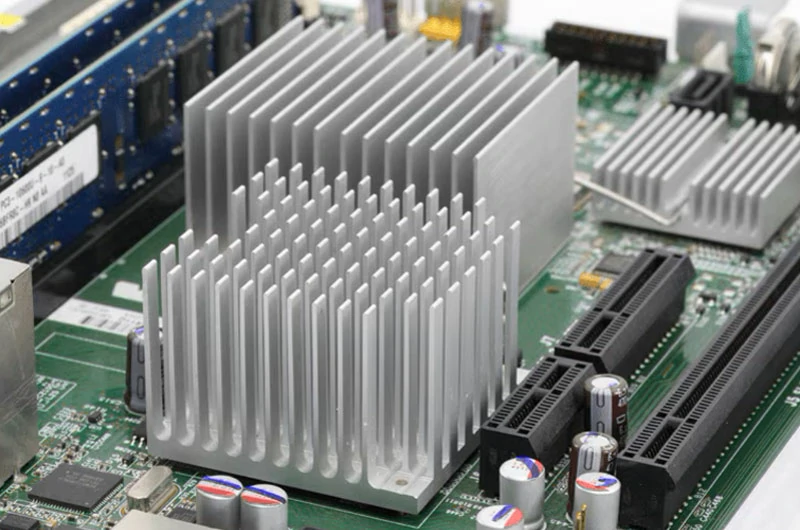

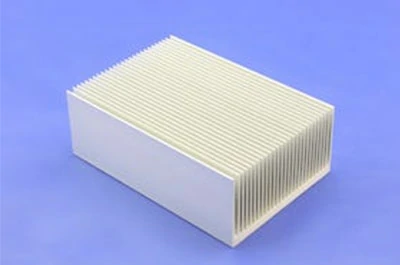

- Plate Fin Heat Sinks (by the foot)

Plate fin heat sinks are cost-effective and provide optimal thermal performance in forced convection when the fins are parallel to the direction of the airflow.

- 6063-T5 aluminum

- low-cost

- anodized

- customizable in length

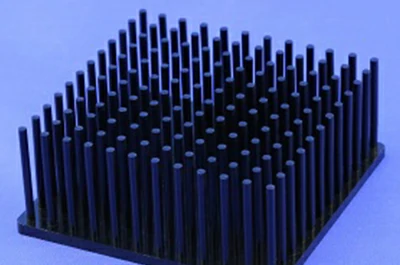

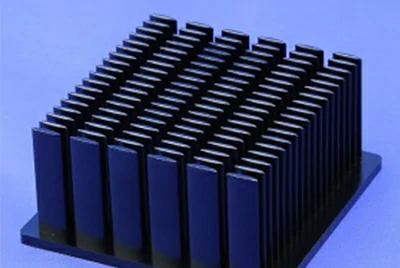

- Round PIN-FIN Heat Sinks

Pin fin heat sinks have minimal impact on changes in airflow direction and can provide excellent thermal performance even under high-speed airflow.

- Omnidirectional characteristics

- low airflow resistance

- high heat dissipation efficiency

- Elliptical PIN-FIN Heat Sinks

An elliptical pin heat sink features low thermal resistance and low pressure drop. Air can smoothly pass through while maintaining speed and high pressure.

- Low thermal resistance

- low pressure drop

- high thermal conductivity

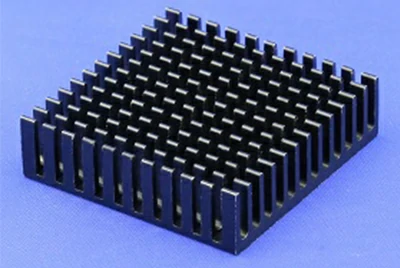

- Cross Cut Heat Sinks

Cross-cutting helps break the stagnant air boundary layer formed on extruded fins, generating turbulence and improving thermal performance.

- 6063-T5

- good mechanics

- high heat dissipation

- Sloped fin Heat Sinks

Sloped fin heat sinks have more surface area, resulting in the lowest thermal resistance from the base to the fins, and they are also lightweight.

- More surface area

- high heat dissipation

- easy installation

Classification of custom aluminum heat sinks

We offer custom manufacturing services for specialized shapes or large heat sinks, providing highly personalized solutions for our customers.

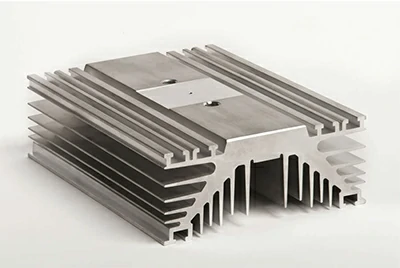

- Extruded Aluminum Heat Sink

- Specifications: Can withstand temperatures up to 400°F.

- Applications: Commonly used in computers, lighting, and electrical equipment with power ratings ranging from 15W to 150W and sizes from 2 inches to 3 inches.

Bonded-Fin Heat Sinks

Bonded-Fin Heat Sinks- Specifications: Can effectively handle temperatures up to 500°F.

- Applications: Bonded fin heat sinks serve equipment with power ratings ranging from 200W to 3kW. Better copper-aluminum bonding.

Skived Heat Sinks

Skived Heat Sinks- Specifications: Can withstand heat from 300°F to 450°F.

- Applications: Sturdy and durable, ideal for high-power equipment up to 250W in automotive and aerospace applications.

Forged Heat Sinks

Forged Heat Sinks- Specifications: High-pressure process, with optimal heat dissipation performance.

- Applications: Commonly used in devices such as CPUs.

Die Cast Heat Sinks

Die Cast Heat Sinks- Specifications: Can handle temperatures from -40°C to 230°C.

- Applications:Diverse in shape, playing a crucial role in LED lighting and automotive electronics.

CNC Machined Heat Sinks

CNC Machined Heat Sinks- Applications: Commonly used in aerospace components.

- Recommendation: High precision, customizable processing.

Stamped Heat Sinks

Stamped Heat Sinks- Specifications: Typical thickness is 0.4 millimeters.

- Applications:Suitable for low-power electronic products such as transistors.

- Recommendation:Low cost and easy for mass production and delivery.

Zipper Fin Heat Sink

Zipper Fin Heat Sink- Specifications: Fin density ranges from 100 to 400 fins per inch.

- Applications: Provides outstanding cooling capacity, making it an ideal choice for aerospace and defense electronic products.

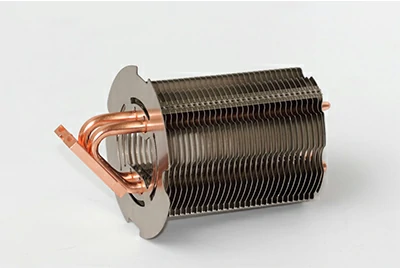

Heat Pipe Heat Sink

Heat Pipe Heat Sink- Specifications: Heat pipes integrated into the design ensure rapid heat dissipation.

- Applications: Suitable for electronic products with a thermal range of 20W to 150W.

How to choose the alloy grade of aluminum heat sink profiles

| Alloy | Thermal conductivity (W/m-K) | Tensile strength (MPa) | Processability | Anodizing |

| 1050 | 229 | 105 | excellent | Difference |

| 6060 | 175 | 260 | good | good |

| 6061 | 187 | 310 | Excellent (suitable for machining) | good |

| 6063 | 201 | 276 | Excellent (suitable for extrusion) | good |

Services offered by Mastar Metal

- For bulk or repeat orders, Mastar Metal offers the most competitive pricing schemes.

- Mastar Metal provides customization services with the ability to manufacture special shapes and large heat sinks.

- Mastar Metal offers thermal analysis testing services to help evaluate the performance of heat sinks.

- Mastar Metal has ample inventory and a variety of mold sizes to provide quick delivery services.

- Mastar Metal provides samples and shipping.

Applications of aluminum heat sinks

- LED cooling: LED fixtures, LED displays.

- Semiconductor cooling: CPU, GPU, ASIC, military equipment.

- Electric vehicle cooling: Motor controllers, battery packs.

- Electronics: TVs, refrigerators, washing machines, air conditioners.

- Electronic components: Power bricks, DSPs, TSOPs, ASICs, DIPs, BGAs, LGAs.

- Communication equipment: Base stations, routers, switches, lasers.

- Medical devices: CT scanners, MRI machines, ultrasound equipment.

- Power generation: Photovoltaic systems, inverters, wind turbines, transformers.

Advantages of aluminum heat sink profiles

- Excellent thermal conductivity

- Low density, lightweight, easy to install

- Non-magnetic, avoids magnetic field interference

- High ductility, easy to process

- Outstanding corrosion resistance

Factors affecting the performance of aluminum heat sinks

Thermal conductivity: The thermal conductivity coefficient measures a material's ability to transfer heat. Materials with higher thermal conductivity have stronger heat transfer capabilities.

Size of the heat sink: Larger heat sinks have a larger surface area, allowing them to dissipate more heat.

Type, number, and arrangement of fins: The type, number, and arrangement of fins on the heat sink can impact its thermal performance. Generally, a higher number of fins, smaller spacing, and tighter arrangement lead to better heat dissipation.

Airflow: Airflow refers to the amount of air passing through the heat sink and is typically measured in cubic meters per second (m³/s). Greater airflow results in more heat being carried away, leading to better heat dissipation.

Surface treatment: Surface treatments of heat sinks can improve their surface emissivity, thereby enhancing heat dissipation efficiency. Common surface treatments for heat sinks include anodizing and coating.

Price of aluminum radiator profiles

- Larger heat sinks typically have higher prices.

- Heat sinks made of more expensive materials have higher prices.

- Heat sinks with more complex surface treatments have higher prices.

- Heat sinks produced using extrusion processes have lower prices. Those made using fin bonding, turning, forging, and die-casting processes have progressively higher prices.

- Generally, the larger the purchase quantity, the lower the unit price.