The power industry includes the production, transmission, distribution, and use of electrical energy. The safe and efficient operation of these processes depends on key materials. Aluminum is essential at every stage, from power generation to usage, because of their wide-ranging applications and importance.

Aluminum is lightweight, cost-effective, and offer excellent electrical conductivity and corrosion resistance, making it ideal for the power industry. Aluminum is also lighter and less expensive than copper, allowing utility companies to install more electrical wiring with fewer support structures.

Aluminum in the power industry: a comprehensive analysis from transmission to distribution

Busbars and tubular busbar for electrical applications

- Aluminum busbar

- Aluminum is used in busbars within electrical distribution facilities, primarily responsible for carrying large currents to circuit breakers. It is renowned for its lightweight nature, high electrical conductivity, and resistance to thermal expansion.

- Aluminum tubular buspipe

- Electrical busbar tubes are tubular busbars used in power distribution systems. They efficiently and safely transmit large currents and are widely used in industrial and commercial applications.

- Lightweight: as one of the lightest alloys, aluminum busbars are easy to install and handle, reducing the burden on installers.

- High conductivity: aluminum busbars offer 50% higher conductivity compared to copper busbars, enhancing current transmission efficiency.

- Custom extruded profiles: utilizing custom extruded profiles, aluminum busbars fit securely and easily into place, simplifying installation. Additional processing, such as rounded corners, is also available.

- High conductivity per unit weight: due to its lightweight nature, aluminum busbars have a 50% higher conductivity per unit weight, allowing for greater current transmission at the same weight.

- High current capacity: capable of handling up to 4000A of current, aluminum busbars can withstand thermal expansion that could otherwise damage the busbar.

- Thermal expansion resistance: effectively resists thermal expansion, ensuring stable operation of the busbars under high load conditions.

Aluminum for transformer

- Due to its lightweight, high conductivity, and corrosion resistance, aluminum materials play a crucial role in transformer manufacturing. They are widely used in windings, winding connections, inductors, wave filters, and support frames.

- High conductivity: the excellent conductivity of aluminum ensures efficient transmission and conversion of electrical energy, enhancing the overall efficiency of the transformer.

- Corrosion resistance and durability: extends the lifespan of transformers, reducing maintenance costs and frequency.

- Good heat dissipation: the excellent thermal conductivity of aluminum helps in effective heat dissipation, protecting internal components of the transformer and maintaining stable operation.

- Wide applicability: aluminum materials are suitable for various parts of transformers, including windings, coils, and oil tanks, with diverse and extensive applications.

- Aluminum foil for transformer

- Aluminum strip for transformer

- Aluminum profile for transformer structure

- Aluminum transformer winding

- Copper or copper clad aluminum winding wire

- Customized Products

Aluminum profiles for electrical power transmission infrastructure

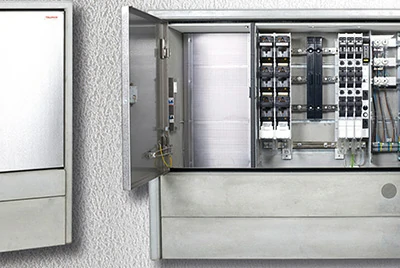

- The raw materials for the support structures of power line transportation, such as poles and towers, are generally aluminum or aluminum alloys. Application scenarios cover a wide range of fields, including transmission towers, utility poles, distribution cabinets, and distribution boxes.

- Corrosion resistance: the corrosion-resistant properties of aluminum ensure the longevity of utility poles used in outdoor environments.

- High strength: aluminum profiles possess excellent mechanical strength and structural stability.

- Good heat dissipation: the high thermal conductivity of aluminum aids in the dissipation of heat in power equipment.

- Customizable and easy to process: aluminum profiles are easy to process and customize, making them suitable for various structures and shapes.

- Wide applications: extensively used in support structures for transmission towers and utility poles, distribution cabinet and box frameworks, cable trays and conduits, and cooling systems for transformer equipment.

Aluminum profiles for generators and motors

Aluminum alloys are widely used in generators and motors. Although there are some differences in their respective operational fields, their constructions are similar, and the application range of aluminum alloys is largely the same.

Due to their lightweight nature, high conductivity, corrosion resistance, and excellent heat dissipation properties, aluminum alloys hold an important position in these devices.

Aluminum profiles for generators

Aluminum profiles for generators- Due to its lightweight nature, high conductivity, and corrosion resistance, aluminum plays a crucial role in the manufacturing of generators. It is widely used in various types of generators, including synchronous generators, asynchronous generators, and DC generators.

- Aluminum Profiles for Motors

- Aluminum alloys are also widely used in the motor industry. Although there are some differences from generators, aluminum alloys in the motor sector are primarily applied in pumps, compressors, fans, air conditioning and refrigeration equipment, drilling rigs, and automotive drive systems.

- High conductivity: the excellent electrical conductivity of aluminum materials enhances the efficiency of generators and motors.

- Corrosion resistance: aluminum's superior corrosion resistance extends the lifespan of generators and motors.

- High strength: aluminum profiles possess good mechanical strength, ensuring the structural stability of generators and motors.

- Good heat dissipation: the high thermal conductivity of aluminum aids in dissipating heat within generators and motors, preventing overheating.

- Aluminum winding wire for motors

- Aluminum heat sinks

- Aluminum housings

- Aluminum alloy rotors

- Aluminum alloy end caps

- Aluminum alloy crankcase

Aluminum in the energy generation sector

Aluminum is used in solar panel frames and mounting systems. Its lightweight nature makes panels easier to transport and install, and its recyclability makes it eco-friendly. The durability and corrosion resistance of aluminum ensure long-term, safe use of solar panels as a sustainable energy source.

Aluminum is often the material of choice for wind turbine blades. The lightweight characteristics of aluminum allow the turbines to rotate efficiently with the wind. Additionally, the durability of aluminum ensures that the turbines can operate reliably for extended periods.

Conductors, cables, and overhead lines

- Aluminum is widely used in conductors, cables, and overhead lines due to its lightweight, high conductivity, cost-effectiveness, corrosion resistance, and excellent tensile strength. It is an ideal material for long-distance power transmission.

- High conductivity: aluminum's excellent conductivity allows for efficient energy distribution.

- Corrosion resistance: aluminum's corrosion resistance makes it ideal for outdoor use, withstanding harsh environmental conditions like sunlight and storms.

- Outstanding tensile strength: aluminum's high tensile strength enables it to endure mechanical loads and environmental pressures such as strong winds and snow in overhead lines.

- Lightweight: aluminum is a lightweight metal, facilitating manufacturing and installation while reducing costs for end consumers.

- Cost-effectiveness: aluminum is more economical than copper, lowering production and maintenance costs, making it a preferred choice in the power industry.

- Environmental friendliness: aluminum is easily recyclable, helping to reduce environmental impact and promote sustainability.

- Aluminum wire rod

- High purity aluminum wire

- CCA wire

- Aluminum winding wire

- Aluminum magnet wire

- Aluminum cable wire

Low-carbon aluminum: a sustainable solution for the power sector

As global attention on sustainability grows, the power sector is actively seeking green solutions. In this context, zero-carbon aluminum is rapidly becoming the preferred choice for the industry. Zero-carbon aluminum not only achieves carbon neutrality in its production process but also boasts excellent performance, making it widely used in power transmission and distribution systems.

Mastar's aluminum materials meet all relevant carbon emission standards and undergo rigorous quality testing to ensure exceptional performance in every batch. Mastar strictly controls material sourcing and quality, committed to promoting the circular economy and ensuring efficient recycling and reuse of aluminum alloys.

Mastar-- your professional supplier of EC grade aluminum and technical service expert

In the power sector, selecting the right materials is crucial. As a professional supplier of EC grade aluminum, Mastar is dedicated to providing high-quality aluminum alloy materials to meet the diverse needs of the energy industry. Whether for power transmission conductors, transformer windings, cables, or motor windings, we offer the finest products and services to ensure optimal performance.

- Diverse aluminum products for power applications: we offer a wide range of aluminum alloy products covering all aspects of power transmission and distribution.

- High-quality assurance: our aluminum alloy materials undergo rigorous quality testing to ensure every batch meets the highest industry standards.

- Fast delivery: we have established an efficient production and logistics system to ensure customers receive the materials they need promptly.

- Expert technical support: we provide comprehensive technical support and customized solutions to ensure optimal performance and usage.

Common questions about aluminum for power applications

Is aluminum a good electrical conductor?

Aluminum is an excellent electrical conductor with a conductivity of 37.7 million siemens per meter (MS/m), which is about 61% of copper's conductivity. This means that aluminum's conductivity is nearly comparable to that of copper, which is recognized as one of the best conductors.

How does aluminum alloy conduct electricity?

In simple terms, aluminum is a metal, which means its atoms have loosely bound electrons in their outermost energy levels. These electrons are not tightly bound to individual atoms but are shared among many atoms within the metal lattice structure. When a voltage is applied to an aluminum conductor (such as a wire), the free electrons are influenced by the electric field, causing them to move and generate an electric current.

How are aluminum conductors manufactured?

To produce wire for cables from aluminum ingots, a process called drawing is used. Drawing involves pulling the metal through a series of dies to gradually reduce its diameter while increasing its length. By drawing the metal through progressively smaller dies, aluminum can be transformed into fine, flexible wire that can then be used as a conductor in applications such as cables.

What is the relationship between aluminum grade and conductivity?

The 1000 series aluminum is the purest and has the best conductivity. EC grade aluminum has the highest conductivity, with common EC grade aluminum being from the 1000 series (such as 1060, 1070, 1350 Al). Additionally, the 6000 series aluminum-magnesium-silicon alloys (such as 6101, 6061, 6063) also have relatively good electrical and thermal conductivity. EC stands for electrical grade, and its conductivity is approximately 61% IACS.

Does aluminum finishing impact electrical conductivity?

| Anodizing Aluminum forms an oxide layer that acts as a natural corrosion-resistant protective layer. This corrosion resistance is a beneficial property for conductors, but the oxide layer hinders conductivity. When aluminum is anodized (an aluminum finishing process), the oxide layer becomes thicker and starts to act as an insulator, which impairs the conductive properties of aluminum. | Powder Coating Powder coating is another surface treatment method for aluminum, forming a coating layer on the aluminum surface. This coating does not act as an insulator but can weaken the original conductivity of the aluminum. |

Which has better conductivity, copper or aluminum?

Without a doubt, copper has a higher conductivity than aluminum. However, while aluminum's conductivity is not as high as copper's, its lightweight nature, lower cost, strong corrosion resistance, and high recyclability provide significant advantages in power transmission. Aluminum is especially beneficial in reducing support loads and promoting sustainable development.