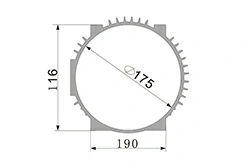

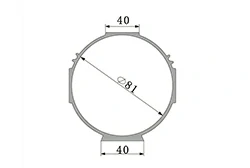

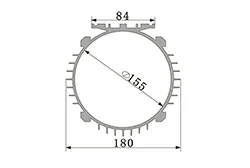

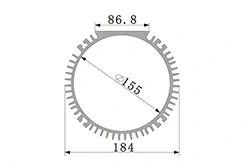

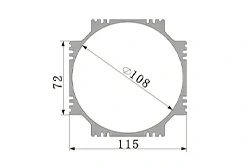

Specifications of aluminium extrusion motor body

Alloy: 6063,6063A

Temper: T5, T6

Manufacturing method: extrusion, casting

Bore concentricity: ≤0.07mm

Inner diameter difference: ≤0.0007D

True roundness: ≤0.0012D

Surface treatment: polished, anodized, electrolytic coloring, powder coating

Deep processing: drilling, bending, welding, cutting

Weight: 5.743kg/m - 8.514kg/m

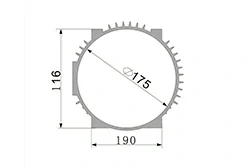

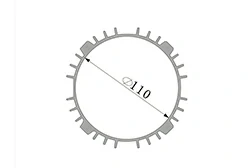

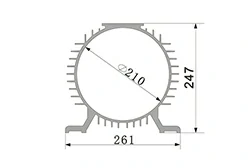

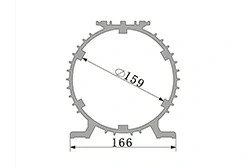

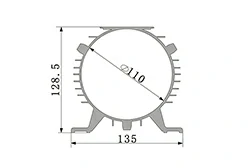

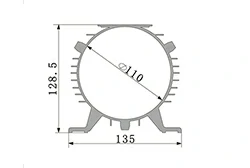

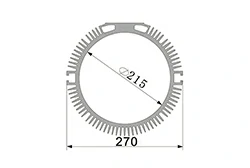

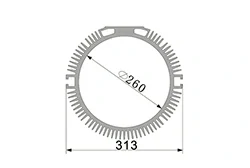

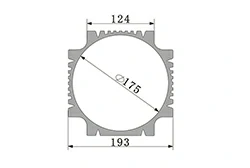

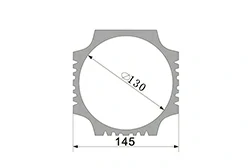

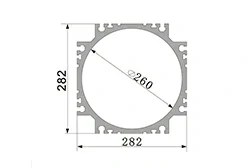

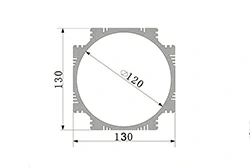

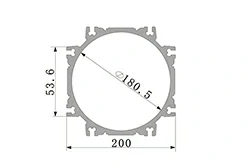

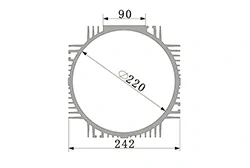

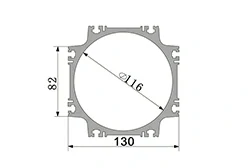

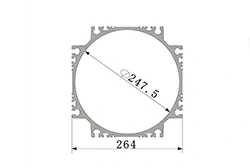

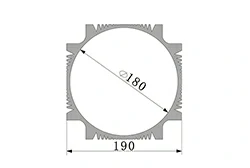

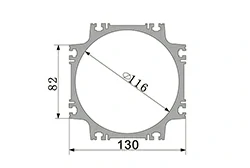

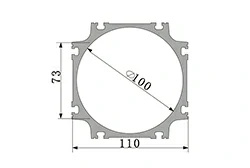

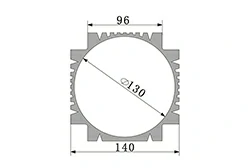

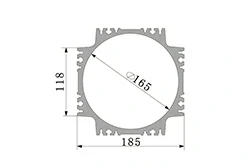

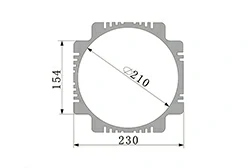

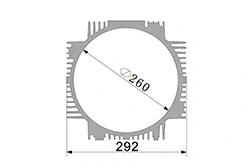

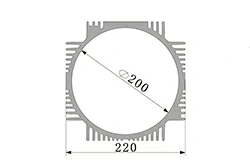

Motor housing aluminum profile hot products

Vertical Motor Housing Aluminum Profile

Vertical Motor Housing Aluminum Profile- Used for vertical mounting of motor casing, generally requires relatively low installation space, considering gravity and stability, usually used for pumps, fans, blowers and other motors that need to be mounted vertically.

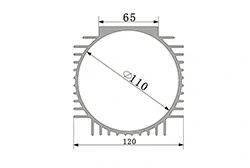

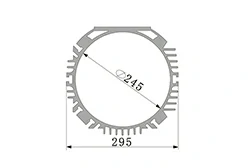

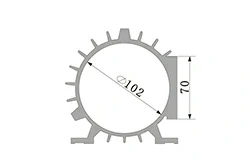

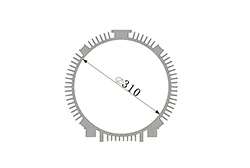

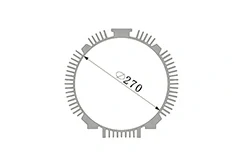

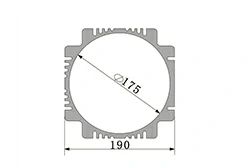

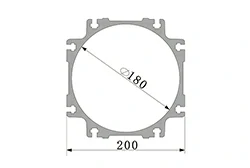

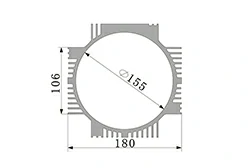

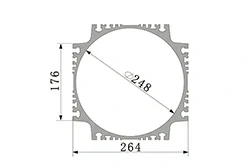

Horizontal Motor Casing Aluminum Profile

Horizontal Motor Casing Aluminum Profile- Motor casing for horizontal mounting with more flexible structural design, usually used for compressors, conveyors, motors required for production lines and other motors that require horizontal mounting.

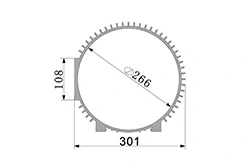

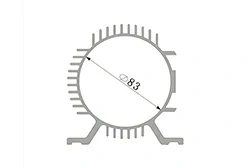

Vacuum Pump Motor Housing Aluminum Profile

Vacuum Pump Motor Housing Aluminum Profile- The motor housing used to protect the internal mechanical parts of the vacuum pump needs to withstand the vibration and pressure during operation, and therefore has to have excellent strength and rigidity. Widely used in semiconductor, pharmaceutical, food processing and other fields.

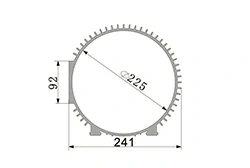

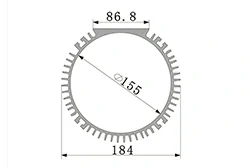

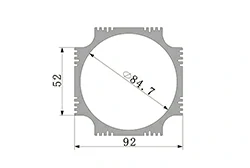

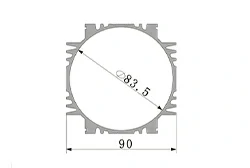

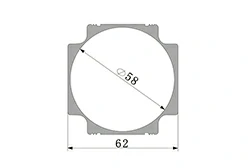

Aluminum profile for servo motor casing

Aluminum profile for servo motor casing- Used for servo motor motor casing, generally water-cooled to meet the needs of precision and compact, usually made of high-strength materials to withstand high dynamic loads, with high dynamic performance and fast shape response, used in robotics, machine tools and other fields.

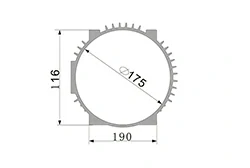

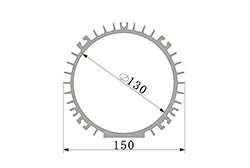

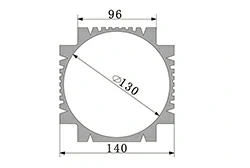

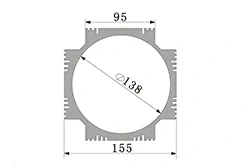

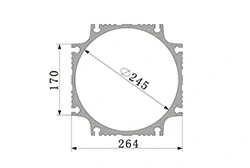

Aluminum profiles for gear motor housings

Aluminum profiles for gear motor housings- Used for motors with geared drive systems, the housing has a gear cavity to provide mechanical support and protection for the gear bearings, and is commonly used in motors that need to provide additional speed or torque, such as geared motors.

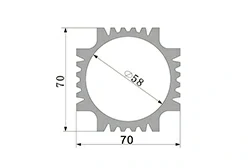

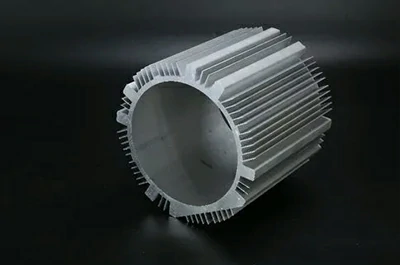

Aluminum profiles for air-cooled motor housings

Aluminum profiles for air-cooled motor housings- Motors that dissipate heat by means of fan or natural convection cooling, suitable for low to medium power motors, commonly found in light mechanical equipment, household appliances and small industrial equipment.

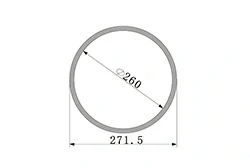

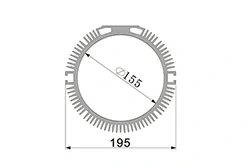

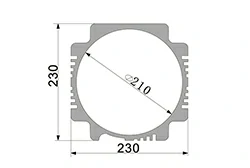

Water-cooled motor housing aluminum profile

Water-cooled motor housing aluminum profile- Designed for motors that require more efficient cooling, the heat is dissipated by circulating water through internal cooling channels for greater efficiency, commonly used for large motors that need to operate under high loads or high temperatures, such as electric vehicles and industrial motors.

Aluminum profiles for automotive motor housings

Aluminum profiles for automotive motor housings- Used for various motors in electric vehicles, such as electric drive systems, generators, starters, electric window motors, wiper motors, etc., which generally need to focus on weight reduction and seismic performance.

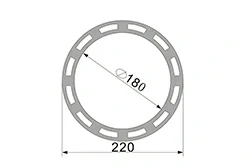

Aluminum profiles for motor housings from Mastar Metal

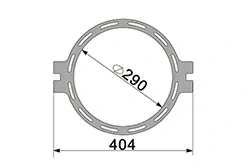

Aluminum profiles for vertical motor housings

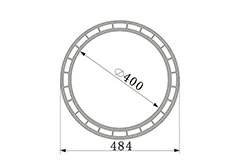

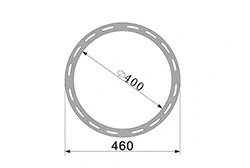

Horizontal motor casing aluminum profile

Aluminum profiles for gear motor housings

Aluminum profiles for water-cooled motor cases

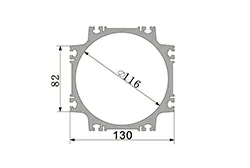

Aluminum profile for servo motor body

Optional surface treatments for aluminum profiles for motor housings

- Mill finish aluminum profiles for motor body

- Anodzing aluminum profiles for motor body

- Powder coatingaluminum profiles for motor body

Advantages of aluminum profiles for motor body

Lightweight design: Aluminum's density is much lower than traditionally used steel, the use of aluminum motor casing can significantly reduce the overall weight of the motor, helping to improve the energy efficiency ratio of the equipment, especially in the field of electric vehicles and aerospace, lightweight is crucial.

Good thermal performance: Aluminum has a high thermal conductivity, and as a motor casing material it can effectively improve heat exchange efficiency, help the motor dissipate heat quickly, reduce performance degradation or damage caused by overheating, and extend the life of the motor.

Design Flexibility: The extrusion process allows for the production of complex shaped motor housings that not only meet specific heat dissipation needs, but also optimize structural design and maximize space utilization, which is especially important for compact motor designs.

Corrosion Resistance: The oxide film that naturally forms on the surface of aluminum provides some protection against corrosion, providing good durability even in harsh environments and reducing maintenance costs.

Economy and Sustainability: While the initial cost of aluminum may be higher than some traditional materials, the fuel savings, reduced maintenance costs, and high recycling value associated with its light weight make it more economical and environmentally friendly in the long run. Aluminum's high recycling rate is also in line with current trends in the circular economy and sustainable development.

Application areas of aluminum profiles for motor body

- Miniature motor shell

- Air conditioning motor shell

- Chiller motor shell

- Water-cooled air conditioner motor shell

- Air compressor motor shell

- Negative pressure fan motor shell

- Electric car motor shell

- Tricycle Motor Housing

- Servo Motor Housing

- Injection molding machine motor

- Cooling tower motor

- Axial fan motor

- Power tool motor

- Geared motors

Extruded aluminum motor body vs. cast aluminum motor body

- Material: industrial grade alu, extruded, denser

- Performance: less porosity, high strength

- Process: Extrusion process

- Appearance: high precision

- Cost: complex process, higher cost

- Application : aerospace, industrial use

- Material: common alu, casting, more voids

- Performance: more voids, low tensile strength

- Process: casting process

- Appearance: rough surface, casting defects

- Cost: low cost, slightly poorer performance

- Applicable: general-purpose machinery

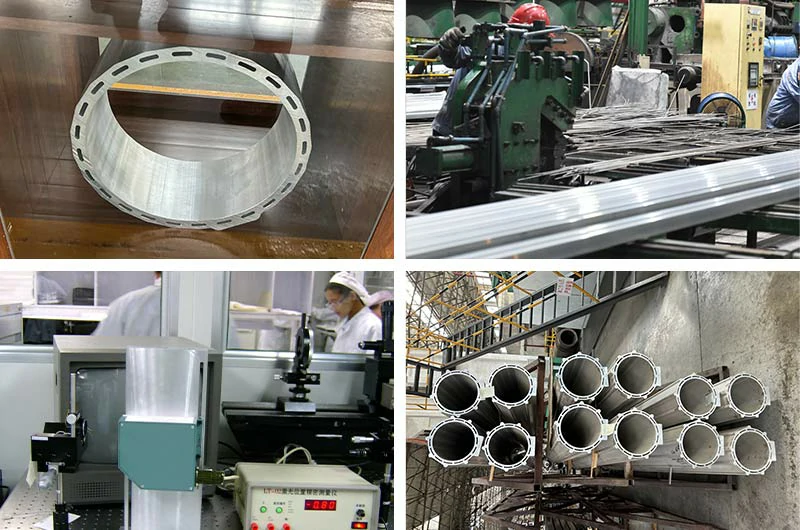

Mastar Metal-quality motor housing profiles supplier

- Product quality: We strictly implement multiple inspection procedures to ensure that all the motor housing profiles out of the warehouse comply with AMS, EN and other extrusion standards, and we monitor the quality of the whole process to ensure that the quality of each motor housing is safe and reliable.

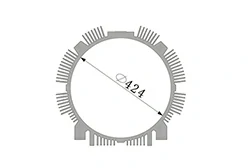

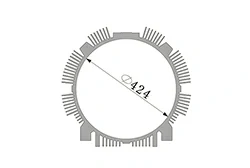

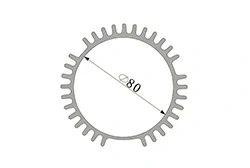

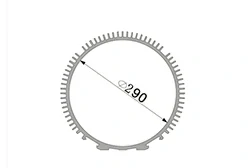

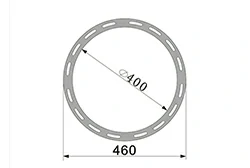

- Production capacity: We are capable of extruding motor housing profiles with a maximum round size of 500mm, as well as other surface treatment, machining, precision cutting and other further processing services.

- Price Advantage: We support retail and end-user customers to purchase large quantities, provide discount and rebate policy for B-end bulk purchase customers, offer open and transparent price, and ensure the price advantage for the same quality of rods.

- Customer service: provide a full range of after-sales service to solve customer worries. Experienced technical team to provide professional advice and guidance, the establishment of a perfect customer service system to ensure quality service experience.

Frequently asked questions

Q: How to solve the problem of high noise?

A: Mastar Metal can make the concentricity of the aluminum alloy motor shell bore ≤ 0.02mm, which can solve the problem of motor running noise due to the poor concentricity of the shell and end cover.

Q: What is the accuracy and hardness of the bore?

A: Mastar Metal's aluminum extruded motor casing bore accuracy reaches grade 8 and HR reaches grade T5.

Q: What are the advantages of extruded motor housing in terms of material utilization?

A: Mastar Metal's aluminum extruded motor shells can be freely cut to length according to the end project requirements, which can save 20% of aluminum usage and significantly reduce production costs.

Q: How to ensure the quality of aluminum extruded motor cases out of the warehouse?

A: All outgoing motor housings are rigorously tested by our quality control team to ensure that the products are well inspected before shipment.