Production of extruded profiles for aluminum alloy door and window structures

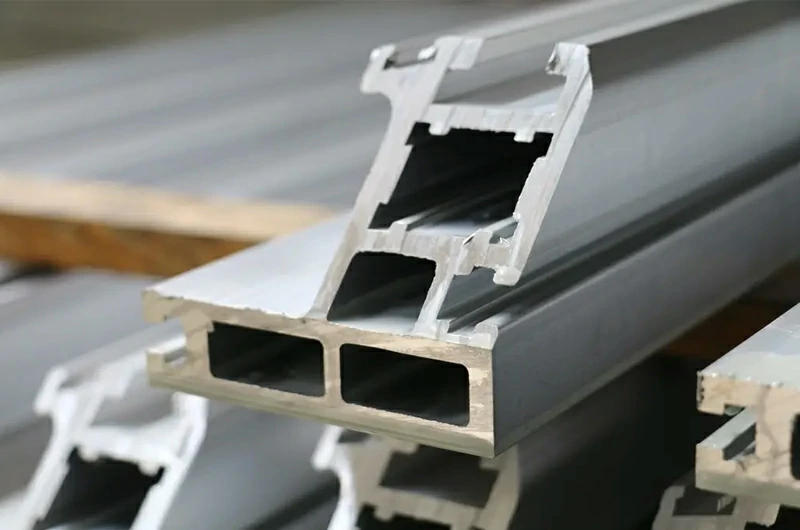

Aluminum alloy door and window profiles are usually produced by extrusion. This processing method is flexible and can produce products of different shapes, specifications and varieties by simply changing molds and other tools. The operation is simple and fast, the efficiency is high, the dimensional accuracy is high, the surface quality is excellent, the overall process flow is simple, and the production operation is convenient.

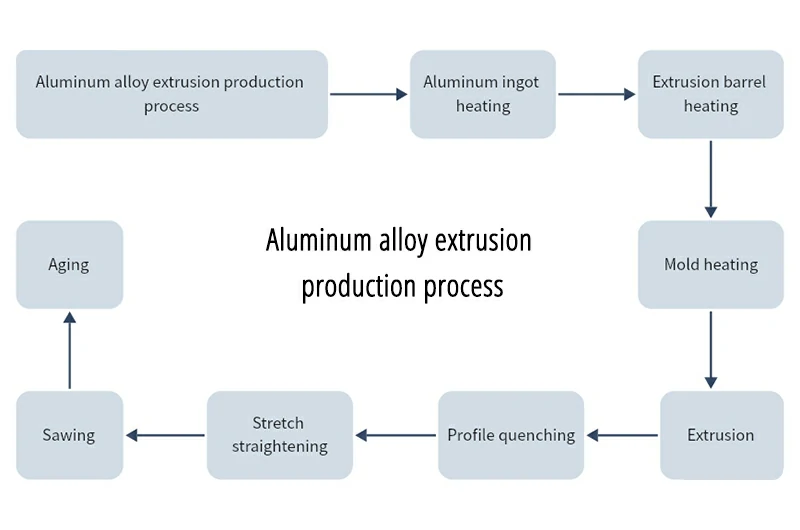

1.Preheat the extrusion barrel and aluminum alloy ingot to ensure the quality of the extrusion process. The upper limit of aluminum alloy for general building doors and windows is 550°C, while 6063 and 6061 alloys require a temperature of 480-520°C.

2.Preheat extrusion tools and dies to ensure smooth extrusion process. The extrusion tool is preheated to 300~400℃, and the size and surface condition are checked before use. The mold also needs to be preheated.

3.Control the extrusion speed to ensure product quality. The principle of extrusion speed selection is to ensure the surface quality of the product, the faster the better, but affected by many factors, it is necessary to select an appropriate extrusion speed based on the actual situation.

4.Aluminum alloy profiles are quenched to obtain the required mechanical properties. Architectural profiles produced by extrusion of 6061, 6063 and other alloys are usually air-cooled or water-cooled quenching on the extruder. Among them, 6061 alloy must be water-cooled.

5.Stretch and straighten the profile to ensure that it has the required shape and size. Stretch straightening should be performed when the profile is cooled to below 50°C. It is strictly prohibited to perform it at high temperature. The stretch rate is generally controlled within the range of 0.05%~2%.

6.Aging treatment is carried out to meet the requirements of building use. Aging treatment is divided into two methods: natural aging and artificial aging, aiming to improve the mechanical properties of aluminum alloy profiles.

Surface treatment of aluminum alloy door and window profiles

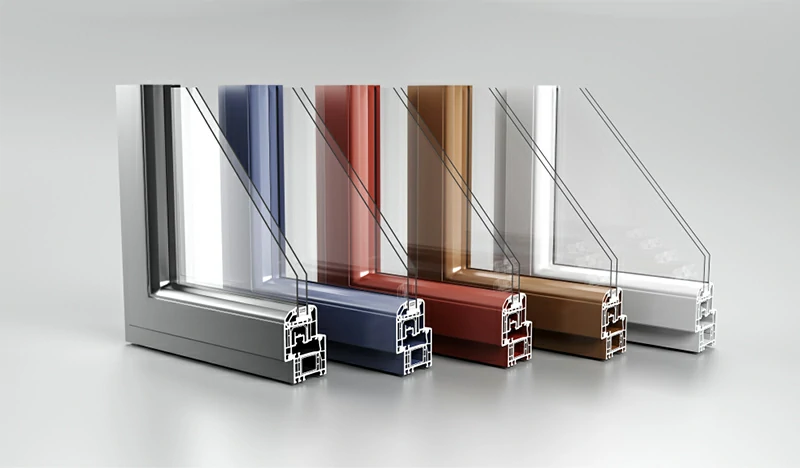

Aluminum and aluminum alloy products have excellent physical, chemical and mechanical properties, which have promoted the rapid development of the aluminum and aluminum alloy manufacturing industry. Surface treatment technology further improves its surface properties, including corrosion resistance, chemical stability and wear resistance. At the same time, these technologies also give aluminum various colors and surface effects, significantly improving its decorative properties.

The surface treatment methods widely used in building aluminum alloy profiles include anodizing treatment, electrophoretic painting treatment and spraying treatment (including powder spraying and fluorocarbon paint spraying processing) etc.

| Comparison of surface treatment properties | ||||

| Project | Anodized film | Electrophoretic paint | Powder spray | Fluorocarbon paint |

| Weather resistance | less | less | Very much | many |

| Corrosion resistance | excellent | excellent | good | many |

| color variety | good | excellent | excellent | excellent |

| Cost of production | Fairly good | Fairly good | good | good |

| Environmental protection of production process | Low | Low | Low | high |

Aluminum profile cutting and frame assembly

After the profile has been extruded and cooled, it can be cut, drilled and the frame assembled. The extruded profile is cut to the length required for the specific window size, and the individual components are assembled using mechanical fasteners or welding, depending on the finished product requirements.

Cutting: Aluminum door and window profiles usually need to be cut according to design requirements to accommodate doors and windows of different sizes and shapes. Cutting can be done by sawing or CNC cutting machinery to ensure straight and accurate cutting.

Drilling: Drilling holes are required to reserve locations for installing hardware accessories and connectors on the door and window frames. Drilling usually uses a drill press or CNC drill press to accurately position and drill holes according to design requirements to ensure that the installation position of hardware accessories is accurate and stable.

Frame assembly: There are three ways to assemble aluminum doors and windows: 45° angle docking, right-angle docking and vertical docking. The connection between horizontal poles and vertical poles generally uses special connectors or aluminum angle steel, and then is fixed with screws, bolts or aluminum studs, and the remaining parts are packaged and protected.

Aluminum alloy window glass and accessories installation

The key to glazing installation is to ensure uniformity, symmetry, and compliance with code dimensional requirements. You can first install the outer rubber strip with tape. After adjusting the position, install the inner rubber strip on enough rubber pads. The strips should be straight, without wrinkles or bulges, and ensure the seams are well bonded.

When installing with sealant, rubber should be placed inside the aluminum frame and sealant should be applied to ensure it is neat, smooth and free of gaps, cracks and holes. Glass beading adopts 45° or 90° joints. Before installation, the glass must be carefully removed to ensure that the joints are tight, flat, and not warped.

The final step in the build process is to install hardware such as handles, locks, hinges, and weatherstripping components. These accessories help improve the functionality, safety and weatherproofing of the final product. Window hardware accessories, sealing brushes, rubber, corners, frames, etc. are assembled into finished windows in accordance with the requirements of the product design drawings.

Quality inspection of aluminum alloy doors and windows

There are many suppliers of aluminum doors and windows, extruded aluminum alloy doors and windows on the market, and the quality and price vary widely. Before purchasing aluminum doors and windows, builders and other large-volume aluminum alloy door and window buyers need to understand the aluminum alloy door and window quality inspection process to ensure that the purchased products meet relevant standards to ensure the normal progress of the project.

Raw material testing: Aluminum profiles for doors and windows are made of 6 series aluminum alloy. The alloy element content should meet the specification requirements and the ratio should be strict to ensure high quality.

Wall thickness detection: The wall thickness of the profile is determined based on the cross-section characteristics of the profile. Generally, the minimum wall thickness is not less than 1.4 mm. Whether the wall thickness is qualified or not will directly affect the service life and safety of doors and windows.

Flatness detection: The surface should be smooth and bright, without depressions or bulges, to ensure a beautiful appearance. Any irregular surfaces will affect the fit and use of doors and windows.

Strength test: The profile should have good strength and should be able to return to its original shape after being bent or twisted by hands. Insufficient strength will cause the product to be easily deformed, affecting performance and safety.

Appearance inspection: There must be no defects such as cracks, burrs, peeling, corrosion, etc. on the surface. The protective film should be intact and bruises should be avoided during transportation to ensure the appearance quality.

Surface treatment inspection:

- Anodizing: The surface should be smooth and can be lightly scratched with a smooth hard object. The white traces should not be wiped off to ensure the quality of the anodized film. There should be no bubbles and ash, and the film thickness should be at least 15um to avoid affecting the corrosion resistance of the aluminum profile.

- Electrophoresis: The coating film should be even and neat, without wrinkles, cracks, bubbles, flow marks, inclusions, stickiness and peeling. The ends are allowed to be partially film-free to ensure coating quality and uniformity.

- Powder coating: The surface should be fine, full, transparent and glossy, and ensure that the decorative surface coating is at least 40um. Avoid gloss loss, powdering, paint peeling and other phenomena to ensure surface quality and long-term use effect.

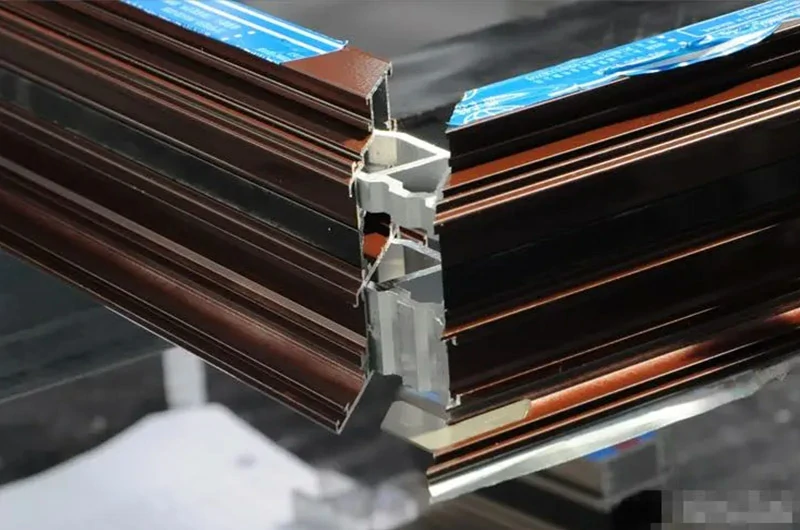

- Surface treatment inspection of wood grain aluminum profiles: The surface should be smooth and flat, with clear wood grain and no obvious inclusions to avoid creases and blurred wood grain patterns. Grooves and corners must be free of creases and wood grain patterns to ensure finish quality and beauty.