Surface treatment is an essential part of the aluminum profile processing process. Through surface treatment, the wear resistance, corrosion resistance, and decorative effect of aluminum profile products can be effectively enhanced.

There are five common surface treatment methods for aluminum profiles: anodizing, powder coating, electrophoresis, fluorocarbon coating, and mechanical surface treatment. Among them, the most common are anodizing and powder coating.

Powder coating

Powder coating is applied to aluminum profiles using electrostatic spraying equipment. The powder adheres evenly to the surface due to static electricity, forming a dense coating film after curing. This film provides excellent corrosion resistance, abrasion resistance, weather resistance, and aesthetics.

Process: Surface pretreatment ->Spraying -> Baking and curing

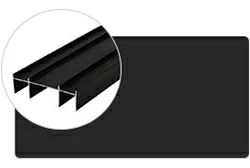

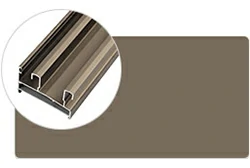

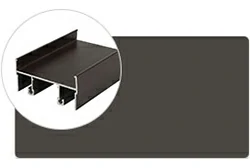

- Black powder coating

- Blue powder coating

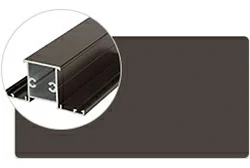

- Bronze powder coating

- Charcoal powder coating

- Ivory powder coating

- White powder coating

Anodizing

Aluminum anodizing is an electrochemical oxidation process. Under specific electrolyte and process conditions, aluminum profiles (anodes) undergo oxidation reactions in the electrolyte, forming a layer of aluminum oxide film on their surface. The oxide film exhibits excellent corrosion resistance, wear resistance, and decorative properties, enhancing the lifespan and aesthetics of aluminum profiles.

After anodizing, aluminum profiles can display various colors, with the most common being black anodized aluminum profiles and white anodized aluminum profiles.

MASTAR's aluminum anodizing process can achieve a maximum length of up to 16 meters and complies with the highest European standards, including Qualanod.

Production process: Degreasing -> Chemical polishing -> Acid etching -> Black film stripping -> Anodizing -> Pre-dyeing -> Dyeing -> Sealing -> Drying

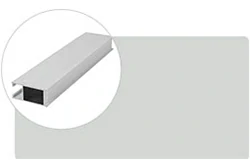

- Black anodized aluminum profiles

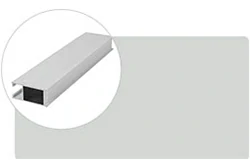

- Silver anodized aluminum profiles

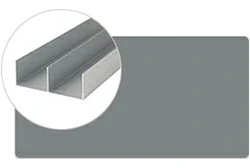

- White anodized aluminum profiles

- Champagne anodized aluminum

- Bronze anodized aluminum

- Champagne anodized aluminum

Electrophoretic deposition

The aluminum electrophoretic coating process involves immersing extruded aluminum profiles into a bath containing a paint solution. A direct current is then applied, causing the paint particles to migrate and deposit onto the surface of the aluminum, forming a uniform and dense coating. This process provides the aluminum with a glossy finish and enhances its corrosion resistance..

Process: Electrolysis (Decomposition) -> Electrophoresis (Migration) -> Electrodeposition (Precipitation) -> Electroosmosis (Dehydration)

Fluorocarbon Coating

Fluorocarbon spraying is a form of electrostatic spraying, which is a liquid spraying method. Using spraying equipment, fluorocarbon paint is sprayed onto the surface of aluminum profiles. After high-temperature baking and curing, a dense fluorocarbon coating is formed. Due to its outstanding corrosion resistance and UV resistance, aluminum profiles with fluorocarbon coatings are widely used in exterior wall decoration applications.

Surface mechanical treatment

Brushed

By drawing the surface of aluminum profiles with a drawing machine, you can obtain a uniform drawing texture and increase the surface gloss and texture. It is the most popular surface treatment method in decoration.

Brushed aluminum profiles can be used for aluminum photo frames, integrated ceilings, cabinets, doors and windows, signs, lighting, indoor and outdoor decorative profiles, aluminum tile decoration, household appliances, bags, gifts, furniture, consumer electronics, etc.

Polishing

Polishing aluminum profiles refers to polishing aluminum profiles through a polishing machine and a mold line to remove scratches, marks and defects on the surface of the aluminum profiles, and obtain a luster such as bright silver (shiny silver), bright gold (shiny gold), etc. Achieve a smooth and bright mirror effect.

Sandblasting

Sandblasting the surface of aluminum profiles with a sandblasting machine can obtain a rough surface and increase surface friction.

Sandblasting improves the mechanical properties of the aluminum profile surface, enhances the fatigue resistance of the aluminum profile, and increases the adhesion between the aluminum profile and the coating.

Why Choose MASTAR?

1. MASTAR has 18 extrusion production lines, 3 powder coating lines (2 horizontal and 1 vertical), 2 anodizing lines, and 1 CNC deep processing line, with a guaranteed annual output value of 60,000 tons.

2. 20,000 sets of standard profile molds, equipped with a large number of standard aluminum profile molds, which can save mold costs.