Bus bars play an indispensable role in the electrical industry, with two main conductor materials being aluminum and copper. So, what are the similarities and differences between aluminum and copper bus bars?

This article will delve into their conductivity, strength, resistance, current carrying capacity, cost, recyclability, and more. By comparing the characteristics of aluminum and copper bus bars, we aim to help you better understand how to choose the appropriate bus bar material for different project requirements.

| Property | Copper | Aluminum |

| Density | 8.96 g/cm³ | 2.71 g/cm³ |

| Melting point | 1085 ℃ | 660 ℃ |

| Conductivity | 100 %IACS | 61 %IACS |

| Thermal conductivity | 401 W/m·K | 237 W/m·K |

| Linear thermal expansion coefficient | 17 μm/m·°C | 23.5 μm/m·°C |

| Resistivity | 1.68 μΩ·cm | 3.47 μΩ·cm |

| Young's modulus | 110 GPa | 70 GPa |

Copper bus bar

Copper bus bars are known for their high conductivity and excellent machinability. As one of the oldest conductor materials, copper exhibits excellent electrical conductivity and can resist most chemical corrosion. In the field of electronics, ETP copper and OFE copper are common materials, both known for their outstanding electrical properties. Despite the high price volatility of copper, it finds widespread use in various applications.

Aluminum bus bar

Aluminum bus bars, as an alternative to copper, are becoming increasingly popular in electrical applications. Aluminum is much lighter than copper, with a density of approximately one-third that of copper, requiring a larger volume for the same weight.

While aluminum's conductivity is slightly lower than that of copper, its lower cost helps to save expenses and achieve lightweight designs in various fields. Aluminum bus bars generally have lower production and installation costs compared to copper, and in many cases, aluminum also exhibits good mechanical machining properties.

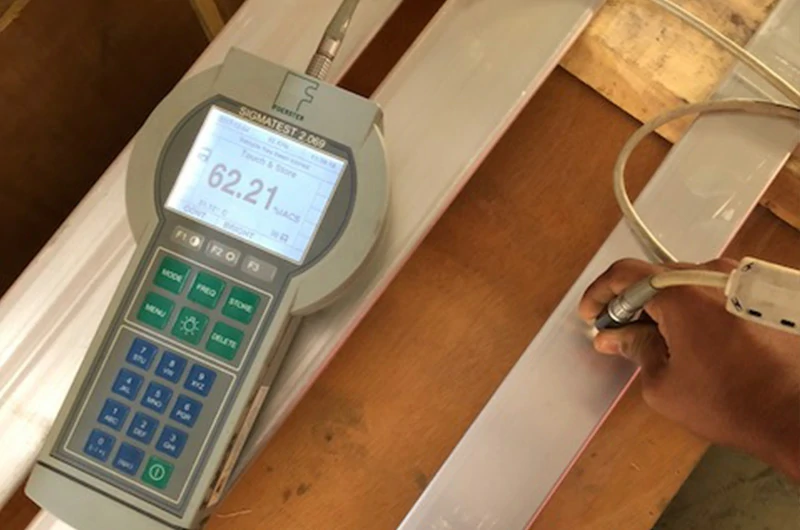

NO.1 Conductivity contrast: aluminum vs. copper busbar

Conductivity is one of the most crucial indicators for bus bar conductors. Typically, copper bus bars have a conductivity of up to 99.8% IACS, while the conductivity of aluminum bus bars varies slightly depending on the alloy. For instance, pure aluminum bus bars like 1350 typically have a conductivity of around 62% IACS, whereas 6101 aluminum bus bars usually exhibit a conductivity of approximately 55% IACS.

| Characteristics | Copper | Aluminum |

| Weight for same conductivity (lb.) | 100 | 54 |

| Cross section for same conductivity | 100 | 156 |

NO.2 Strength comparison: aluminum busbars vs. copper busbar

Strength is also a critical indicator for bus bars. Copper has a tensile strength of about 32,000 psi, while the tensile strength of electrical-grade aluminum alloy 6101 is approximately 28,000 psi.

| Characteristics | Copper | Aluminum |

| Tensile strength (Ib/in2) | 50000 | 32000 |

| Tensile strength for same conductivity (lb.) | 50000 | 50000 |

NO.3 Resistance variation: copper busbars vs. aluminum busbar

Bus bar resistance is one of the critical performance indicators for bus bar conductors. Volume-wise, copper outperforms aluminum. Copper offers lower resistance, reduced power loss, decreased voltage drop, and higher current-carrying capacity, enhancing the electrical efficiency of bus bar systems.

| Characteristics | Copper | Aluminum |

| Specific resistance(ohmscir/mil ft) (20℃ ref) | 10.6 | 18.52 |

| Coefficient of expansion (per deg. C × 10-6) | 16.6 | 23 |

NO.4 Current-carrying capacity: aluminum vs. copper busbar

Current carrying capacity refers to the maximum current that a bus bar can handle, determined by factors such as conductor material resistance, temperature rise, and mechanical strength.

In general, copper has a higher conductivity, resulting in a higher current carrying capacity for copper bus bars compared to aluminum bus bars of the same cross-sectional area. This means that under the same current load, copper bus bars experience relatively lower temperature rises, thus enhancing system stability and reliability.

Although the current carrying capacity of aluminum bus bars is lower than that of copper bus bars, they can still handle currents of up to 4000A, which is sufficient for many applications.

| Comparison Table of Copper and Aluminum Ampacity | ||||||||||||

| Ampacity Conversion Chart | Copper C110 | 30° C Rise | 50° C Rise | 65° C Rise | Aluminum 6101 | 30° C Rise | 50° C Rise | 65° C Rise | ||||

| Flat Bar Size in Inches | Sq. In | Circ Mils Thousands | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp* | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp** | ||||

| 1/16 x 1/2 | 0.0312 | 39.7 | 0.121 | 264 | 103 | 136 | 157 | 0.037 | 494 | 58 | 76 | 88 |

| 1/16 x 3/4 | 0.0469 | 59.7 | 0.181 | 175 | 145 | 193 | 225 | 0.055 | 327 | 81 | 108 | 126 |

| 1/16 x 1 | 0.0625 | 79.6 | 0.242 | 132 | 187 | 250 | 285 | 0.073 | 247 | 105 | 140 | 160 |

| 1/16 x 1 1/2 | 0.0938 | 119 | 0.362 | 87.7 | 270 | 355 | 410 | 0.110 | 164 | 151 | 199 | 230 |

| 1/16 x 2 | 0.125 | 159 | 0.483 | 65.8 | 345 | 460 | 530 | 0.146 | 123 | 193 | 258 | 297 |

| 1/8 x 1/2 | 0.0625 | 79.6 | 0.241 | 132 | 153 | 205 | 235 | 0.073 | 247 | 86 | 115 | 132 |

| 1/8 x 3/4 | 0.0938 | 119 | 0.362 | 87.7 | 215 | 285 | 325 | 0.110 | 164 | 120 | 160 | 182 |

| 1/8 x 1 | 0.125 | 159 | 0.483 | 65.8 | 270 | 360 | 415 | 0.146 | 123 | 151 | 202 | 232 |

| 1/8 x 1 1/2 | 0.188 | 239 | 0.726 | 43.8 | 385 | 510 | 590 | 0.220 | 82 | 216 | 286 | 330 |

| 1/8 x 2 | 0.25 | 318 | 0.966 | 32.9 | 495 | 660 | 760 | 0.293 | 62 | 277 | 370 | 426 |

| 1/8 x 2 1/2 | 0.312 | 397 | 1.210 | 26.4 | 600 | 800 | 920 | 0.365 | 49 | 336 | 448 | 515 |

| 1/8 x 3 | 0.375 | 477 | 1.450 | 21.9 | 710 | 940 | 1100 | 0.439 | 41 | 398 | 526 | 616 |

| 1/8 x 3 1/2 | 0.438 | 558 | 1.690 | 18.8 | 810 | 1100 | 1250 | 0.512 | 35 | 454 | 616 | 700 |

| 1/8 x 4 | 0.5 | 636 | 1.930 | 16.5 | 900 | 1200 | 1400 | 0.585 | 31 | 504 | 672 | 784 |

| 3/16 x 1/2 | 0.09375 | 119 | 0.362 | 87.7 | 195 | 260 | 300 | 0.110 | 164 | 109 | 146 | 168 |

| 3/16 x 3/4 | 0.141 | 179 | 0.545 | 58.4 | 270 | 360 | 415 | 0.165 | 109 | 151 | 202 | 232 |

| 3/16 x 1 | 0.188 | 239 | 0.726 | 43.8 | 340 | 455 | 520 | 0.220 | 82 | 190 | 255 | 291 |

| 3/16 x 1 1/2 | 0.281 | 358 | 1.090 | 29.3 | 480 | 630 | 730 | 0.329 | 55 | 269 | 353 | 409 |

| 3/16 x 2 | 0.375 | 477 | 1.450 | 21.9 | 610 | 810 | 940 | 0.439 | 41 | 342 | 454 | 526 |

| 3/16 x 2 1/2 | 0.469 | 597 | 1.810 | 17.5 | 740 | 980 | 1150 | 0.549 | 33 | 414 | 549 | 644 |

| 3/16 x 3 | 0.562 | 715 | 2.170 | 14.6 | 870 | 1150 | 1350 | 0.658 | 27 | 487 | 644 | 756 |

| 3/16 x 3 1/2 | 0.656 | 835 | 2.530 | 12.5 | 990 | 1300 | 1500 | 0.768 | 23 | 554 | 728 | 840 |

| 3/16 x 4 | 0.75 | 955 | 2.900 | 11 | 1100 | 1450 | 1700 | 0.878 | 21 | 616 | 812 | 952 |

| 1/4 x 1/2 | 0.125 | 159 | 0.483 | 65.8 | 240 | 315 | 360 | 0.146 | 123 | 134 | 176 | 202 |

| 1/4 x 3/4 | 0.188 | 239 | 0.726 | 43.8 | 320 | 425 | 490 | 0.220 | 82 | 179 | 238 | 274 |

| 1/4 x 1 | 0.25 | 318 | 0.966 | 32.9 | 400 | 530 | 620 | 0.293 | 62 | 224 | 297 | 347 |

| 1/4 x 1 1/2 | 0.375 | 477 | 1.450 | 21.9 | 560 | 740 | 880 | 0.439 | 41 | 314 | 414 | 482 |

| 1/4 x 2 | 0.5 | 637 | 1.930 | 16.5 | 710 | 940 | 1100 | 0.585 | 31 | 398 | 526 | 616 |

| 1/4 x 2 1/2 | 0.625 | 796 | 2.410 | 13.2 | 850 | 1150 | 1300 | 0.731 | 25 | 476 | 644 | 728 |

| 1/4 x 3 | 0.75 | 955 | 2.900 | 11 | 990 | 1300 | 1550 | 0.878 | 21 | 554 | 728 | 868 |

| 1/4 x 3 1/2 | 0.875 | 1110 | 3.380 | 9.4 | 1150 | 1500 | 1750 | 1.024 | 18 | 644 | 840 | 980 |

| 1/4 x 4 | 1 | 1270 | 3.860 | 8.23 | 1250 | 1700 | 1950 | 1.170 | 15 | 700 | 952 | 1092 |

| 1/4 x 5 | 1.25 | 1590 | 4.830 | 6.58 | 1500 | 2000 | 2350 | 1.463 | 12 | 840 | 1120 | 1316 |

| 1/4 x 6 | 1.5 | 1910 | 5.800 | 5.49 | 1750 | 2350 | 2700 | 1.755 | 10 | 980 | 1316 | 1512 |

| 3/8 x 3/4 | 0.281 | 368 | 1.090 | 29.3 | 415 | 550 | 630 | 0.329 | 55 | 232 | 308 | 353 |

| 3/8 x 1 | 0.375 | 477 | 1.450 | 21.9 | 510 | 680 | 790 | 0.439 | 41 | 286 | 381 | 442 |

| 3/8 x 1 1/2 | 0.562 | 715 | 2.170 | 14.6 | 710 | 940 | 1100 | 0.658 | 27 | 398 | 526 | 616 |

| 3/8 x 2 | 0.75 | 955 | 2.900 | 11 | 880 | 1150 | 1350 | 0.878 | 21 | 493 | 644 | 756 |

| 3/8 x 2 1/2 | 0.938 | 1190 | 3.620 | 8.77 | 1050 | 1400 | 1600 | 1.097 | 16 | 5.88 | 784 | 896 |

| 3/8 x 3 | 1.12 | 1430 | 4.350 | 7.35 | 1200 | 1600 | 1850 | 1.310 | 14 | 672 | 896 | 1036 |

| 3/8 x 3 1/2 | 1.31 | 1670 | 5.060 | 6.38 | 1350 | 1800 | 2100 | 1.533 | 12 | 756 | 1008 | 1176 |

| 3/8 x 4 | 1.5 | 1910 | 5.8 | 5.49 | 1500 | 2000 | 2350 | 1.755 | 10 | 840 | 1120 | 1316 |

| 3/8 x 5 | 1.88 | 2390 | 7.26 | 4.38 | 1800 | 2400 | 2800 | 2.2 | 8 | 1008 | 1344 | 1568 |

| 3/8 x 6 | 2.25 | 2860 | 8.69 | 3.66 | 2100 | 2800 | 3250 | 2.633 | 7 | 1176 | 1568 | 1820 |

| 1/2 x 1 | 0.5 | 637 | 1.93 | 16.5 | 620 | 820 | 940 | 0.585 | 31 | 347 | 459 | 526 |

| 1/2 x 1 1/2 | 0.75 | 955 | 2.9 | 11 | 830 | 1100 | 1250 | 0.878 | 21 | 465 | 616 | 700 |

| 1/2 x 2 | 1 | 1270 | 3.86 | 8.23 | 1000 | 1350 | 1550 | 1.17 | 15 | 560 | 756 | 868 |

| 1/2 x 2 1/2 | 1.25 | 1590 | 4.83 | 6.58 | 1200 | 1600 | 1850 | 1.463 | 12 | 672 | 896 | 1036 |

| 1/2 x 3 | 1.5 | 1910 | 5.8 | 5.49 | 1400 | 1850 | 2150 | 1.755 | 10 | 784 | 1036 | 1204 |

| 1/2 x 3 1/2 | 1.75 | 2230 | 6.76 | 4.7 | 1550 | 2100 | 2400 | 2.048 | 9 | 868 | 1176 | 1344 |

| 1/2 x 4 | 2 | 2550 | 7.73 | 4.11 | 1700 | 2300 | 2650 | 2.34 | 8 | 952 | 1288 | 1484 |

| 1/2 x 5 | 2.5 | 3180 | 9.66 | 3.29 | 2050 | 2750 | 3150 | 2.925 | 6 | 1148 | 1540 | 1764 |

| 1/2 x 6 | 3 | 3820 | 11.6 | 2.74 | 2400 | 3150 | 3650 | 3.51 | 5 | 1344 | 1764 | 2044 |

| 1/2 x 8 | 4 | 5090 | 15.5 | 2.06 | 3000 | 4000 | 4600 | 4.68 | 4 | 1680 | 2240 | 2576 |

Click to see all

Click to see all Therefore, when designing power systems, it is necessary to consider the current carrying capacity of both copper and aluminum bus bars comprehensively. Based on specific application requirements, space limitations, and environmental conditions, selecting the appropriate material and size is crucial to ensure the safe and stable operation of the system.

NO.5 Connection methods: aluminum vs. copper busbar

Common connection methods for aluminum and copper bus bars include bolted connections, crimp connections, welded connections, plug-in connections, and soldered connections. Although the connection methods for both are similar, due to copper's better conductivity, copper bus bars can use smaller contact areas. When selecting a connection method, factors such as engineering requirements, construction conditions, technical specifications, and costs should be considered. It is essential to ensure that the surface is clean, the contact area is sufficiently large, and necessary tests are conducted to ensure a secure and reliable connection.

NO.6 Weight consideration: copper vs. aluminum busbar

The difference in weight between aluminum and copper bus bars mainly stems from their different densities. Copper has a density of approximately 8.96 grams per cubic centimeter, while aluminum has a density of about 2.7 grams per cubic centimeter. Therefore, copper bus bars of the same cross-sectional area weigh approximately 3.3 times more than aluminum bus bars. For example, a 100 square millimeter copper bus bar weighs around 8.9 kilograms, while an aluminum bus bar of the same cross-sectional area weighs around 2.7 kilograms. The choice between copper and aluminum bus bars depends on the specific requirements: copper bus bars are preferred when higher conductivity and thermal conductivity are needed, while aluminum bus bars are chosen to reduce weight. Click to calculcate the weight of aluminum bus bar.

NO.7 Cost analysis: copper busbars vs. aluminum busbar

There is a significant price difference between aluminum and copper bus bars, with copper being much more expensive than aluminum. Additionally, aluminum prices tend to be more stable compared to copper, with less influence from consumer demand and other political and economic factors. According to data from the London Metal Exchange, the current price ratio between copper and aluminum exceeds 2.6:1, indicating a substantial cost difference between them.

As a result, metal stockists and project managers often prefer aluminum bus bars when their performance requirements are met, as it allows for more accurate cost predictions, thus saving project expenses. The lightweight nature of aluminum bus bars also saves a considerable amount on transportation and installation costs, making them a more cost-effective choice in the design of power systems.

NO.8 Environmental impact: copper vs. aluminum busbar

There are some differences between aluminum and copper bus bars in terms of recyclability. Although both aluminum and copper are 100% recyclable metals, their recycling processes have varying degrees of environmental impact.

Aluminum is one of the most recycled industrial metals, with approximately 75% of recycled aluminum still in use. In contrast, the recycling rate for copper is slightly lower, at about 65%. Additionally, the energy required to recycle aluminum is only 5% of that needed for primary production, while recycling the same amount of copper requires 15% of the energy needed for mining and extraction. This indicates that the recycling process for aluminum has a smaller environmental impact, as it relies less on non-ecological mining and extraction processes and generates less energy waste.

In summary, aluminum bus bars have a relative advantage in recyclability, as their recycling process has a smaller environmental impact and helps conserve resources and reduce costs.

NO.9 Application specifics: choosing between copper and aluminum busbar

Aluminum bus bars are typically used in applications where cost and weight requirements are high, such as interior electrical systems in buildings, small industrial equipment, and low-voltage power distribution systems. Compared to copper bus bars, aluminum bus bars have lower density and cost. Therefore, in cost- and weight-sensitive applications, aluminum bus bars are often the more economical and suitable choice.

On the other hand, copper bus bars are commonly used in applications that require high electrical conductivity and reliability, such as large industrial equipment, substations, and high-voltage power distribution systems. Due to their lower resistance, excellent conductivity, and stability, copper bus bars can withstand higher current loads and maintain stable resistance and temperature rise over long-term use. Therefore, they are widely used in power systems with high-performance and stability requirements.

In summary, aluminum and copper bus bars play important roles in different application scenarios. Choosing the appropriate material depends on specific project requirements, performance criteria, and cost considerations.

Summarize

In summary, there are significant differences between aluminum and copper bus bars in terms of cost, weight, recyclability, and environmental friendliness. Aluminum bus bars have lower manufacturing costs, are lighter in weight, and have lower transportation and installation costs, but their conductivity is slightly lower than that of copper bus bars. On the other hand, copper bus bars, while more expensive and heavier, offer excellent conductivity and higher reliability.

Therefore, when choosing between aluminum and copper bus bars, it's essential to conduct a comprehensive assessment based on specific project requirements. If the project demands lower costs and weight with moderate conductivity requirements, then aluminum bus bars may be the more suitable choice. If the project requires high conductivity and reliability, with a higher budget, then copper bus bars might be more appropriate.

Taking into account project requirements, budget, performance criteria, and environmental factors, selecting the most suitable bus bar material is crucial for the successful implementation of the project.

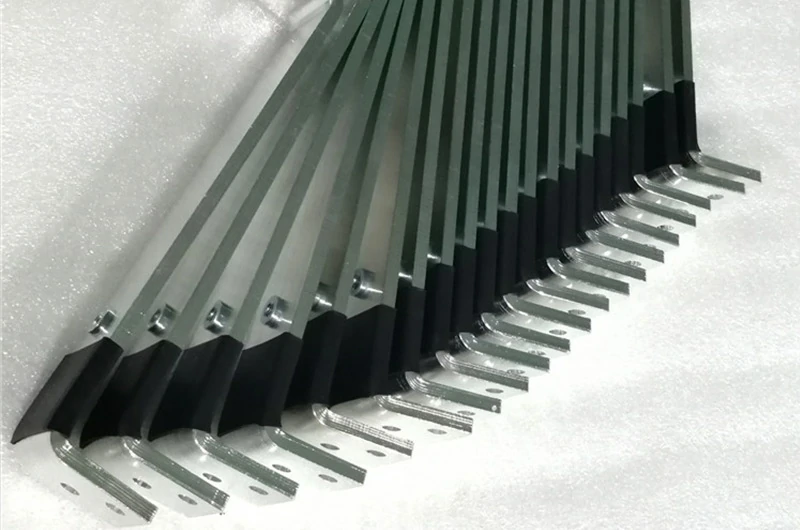

Mastar Metal EC grade aluminum busbar product list

- 6101 EC grade Aluminum Busbar

- High mechanical strength

- Electrical conductivity of 59% IACS

- Good thermal stability

- CCA EC grade Aluminum Busbar

- High electrical conductivity

- Good machinability

- Good processability

- 1350 Aluminum Busbar

- Conductivity of 61% IACS

- Aluminum content up to 99.5%

- Good corrosion resistance

- 1370 Aluminum Busbar

- Conductivity: 61% IACS

- High strength

- Good processability

- 1060 Aluminum Busbar

- Conductivity: 61% IACS

- Good corrosion resistance

- No cracking in 90° bends

- 1070 Aluminum Busbar

- Aluminum content: 99.7%

- Conductivity: 61% IACS

- High ductility

- 1050 Aluminum Busbar

- Conductivity: 60% IACS

- Excellent corrosion resistance

- No cracking during 90° bending

- 6063 Aluminum Busbar

- Conductivity: 59% IACS

- Good mechanical properties

- Heat treatable

Click to collapse

Click to collapse