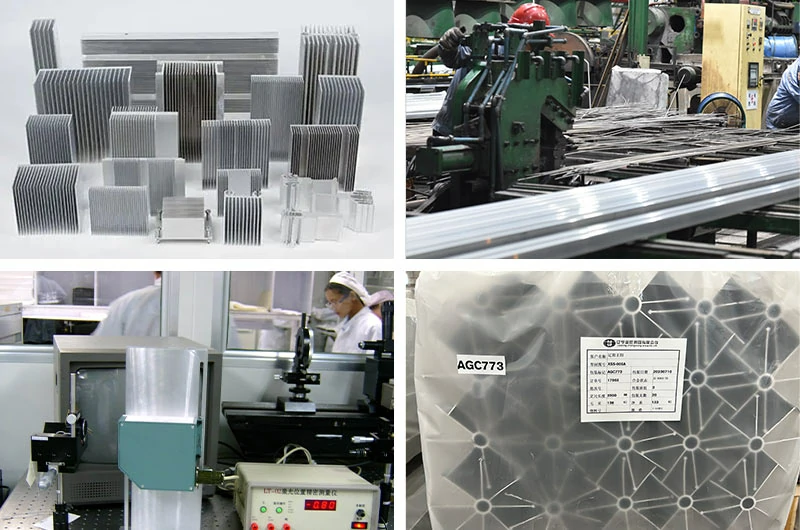

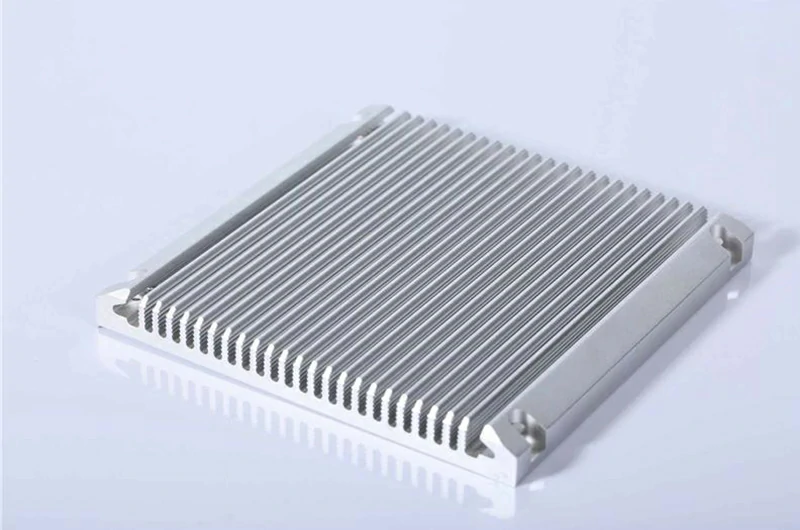

Mastar Metal provides a rich inventory of profiles with a wide range of mold sizes. Additionally, we offer precision cutting, milling, drilling, and slotting services to further optimize the diversity and thermal performance of heat sink profiles.

Extruded heat sink specifications

Alloys: 6061, 6063, 6005

Maximum Width: 24 inches (609 mm)

Maximum Height: 60mm

Maximum Fin Height-to-Fin Gap Ratio: 22

Length: 10-6000 mm (customizable for large heat sinks)

Surface Finish: Anodizing, polishing, electroplating, painting, laser marking, Alodine 5200, Acculabs 628

Colors: Black, silver, blue, red

Processing: CNC machining, cutting, punching, bending, welding, milling, CNC control

Standards: EN 13849, ASTM B221, SAE J461, DIN 1728, TS 5483

Certifications: RoHS, CE, SGS, ISO, TUV SUD, UL

Mastar Metal offers the following services

- For bulk orders or repeat customers, Mastar Metal provides the most competitive prices or waives the tooling/mold fee.

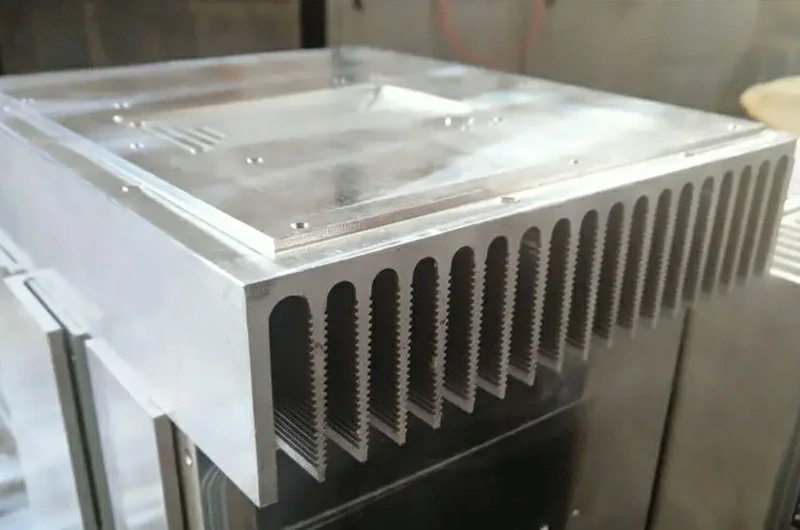

- Mastar Metal provides custom services with the capability to manufacture special shapes and large heat sinks.

- Mastar Metal offers thermal analysis testing services to help evaluate the performance of heat sinks.

- Mastar Metal has ample inventory and a variety of mold sizes to provide quick delivery services.

- Mastar Metal provides samples and shipping.

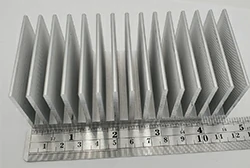

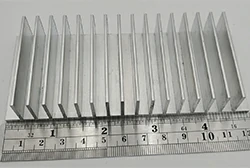

Standard extruded heat sink dimensions

All our extruded heat sinks are available for sale by the foot. If you have any questions, please contact us, and we'll be happy to assist you.Quick Quote

6063 T5 0.3543" Extruded Aluminum Heat SinkInquire Now

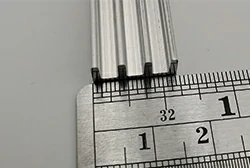

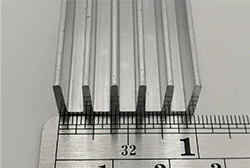

6063 T5 0.3543" Extruded Aluminum Heat SinkInquire NowBase Width: 0.3543", Fin Height: 0.138", Base Height: 0.059"  6063 T5 0.601" Extruded Aluminum Heat SinkInquire Now

6063 T5 0.601" Extruded Aluminum Heat SinkInquire NowBase Width: 0.601", Fin Height:0.210", Base Height:0.090"  6063 T5 1.000" Extruded Aluminum Heat SinkInquire Now

6063 T5 1.000" Extruded Aluminum Heat SinkInquire NowBase Width: 1.000", Fin Height:0.366", Base Height:0.098"  6063 T5 2.000" Round extruded radiatorInquire Now

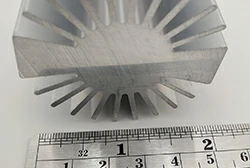

6063 T5 2.000" Round extruded radiatorInquire NowBase Width: 2.00", Base inner diameter: 1.00", circumference: 2.062", outer circumference: 24.353"  6063 T5 2.079" Extruded Aluminum Heat SinkInquire Now

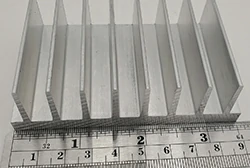

6063 T5 2.079" Extruded Aluminum Heat SinkInquire NowBase Width: 2.079", Fin Height: 0.366", Base Height:0.098"  6063 T5 3.500" Extruded Aluminum Heat SinkInquire Now

6063 T5 3.500" Extruded Aluminum Heat SinkInquire NowBase Width: 3.500", Fin Height: 0.75", Base Height:0.300"  6063 T5 4.230" Extruded Aluminum Heat SinkInquire Now

6063 T5 4.230" Extruded Aluminum Heat SinkInquire NowBase Width: 4.230", Fin Height: 0.75", Base Height:0.300"  6063 T5 4.600" Sawtooth fin aluminum radiatorInquire Now

6063 T5 4.600" Sawtooth fin aluminum radiatorInquire NowBase Width: 4.600", Fin Height: 1.451", Base Height:0.230"  6063 T5 4.850" Extruded Aluminum Heat SinkInquire Now

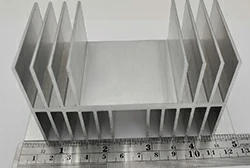

6063 T5 4.850" Extruded Aluminum Heat SinkInquire NowBase Width: 4.850", Fin Height: 0.66", Base Height:0.140"  6063 T5 5.000" Extruded aluminum heat sink (for semiconductors)Inquire Now

6063 T5 5.000" Extruded aluminum heat sink (for semiconductors)Inquire NowBase Width: 5.000", Heat sink height: 1.25", Base Height:0.200"  6063 T5 6.080" Extruded Aluminum Heat SinkInquire Now

6063 T5 6.080" Extruded Aluminum Heat SinkInquire NowBase Width: 6.080", Fin Height: 0.25", Base Height:0.25"  6063 T5 8.000" Serrated Fin Aluminum Heat SinkInquire Now

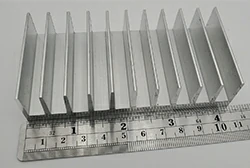

6063 T5 8.000" Serrated Fin Aluminum Heat SinkInquire NowBase Width: 8.000", Fin Height: 3.000", Base Height:0.375"  6063 T5 10.000" Serrated Fin Aluminum Heat SinkInquire Now

6063 T5 10.000" Serrated Fin Aluminum Heat SinkInquire NowBase Width: 10.000", Fin Height: 1.000", Base Height:0.300"  6063 T5 12.000" Serrated Fin Aluminum Heat SinkInquire Now

6063 T5 12.000" Serrated Fin Aluminum Heat SinkInquire NowBase Width: 12.000", Fin Height: 1.000", Base Height:0.300"

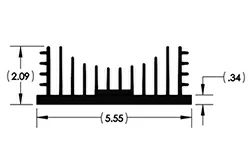

Special extruded heat sink dimensions

We have the most comprehensive selection of heat sink profile molds in the industry and offer customization and length cutting services.

If you need heat sink profiles or thermal solutions, please feel free to contact us anytime.

- 5.55" Extruded Aluminum Heat Sink

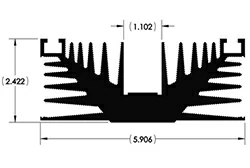

- 5.906" Extruded Aluminum Heat Sink

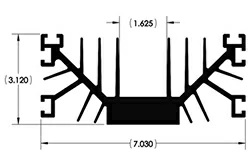

- 7.030" Extruded Aluminum Heat Sink

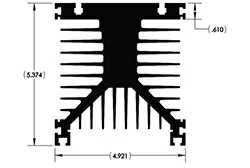

- 4.921" Extruded Aluminum Heat Sink

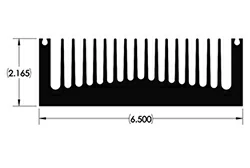

- 6.500" Extruded Aluminum Heat Sink

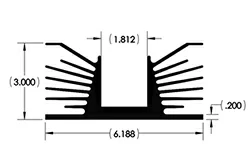

- 6.188" Extruded Aluminum Heat Sink

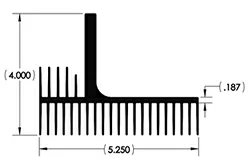

- 5.250" Extruded Aluminum Heat Sink

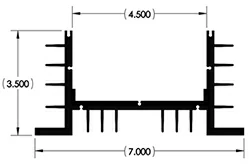

- 7.000" Extruded Aluminum Heat Sink

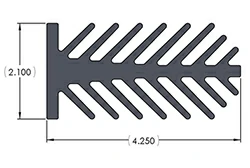

- 4.250" Extruded Aluminum Heat Sink

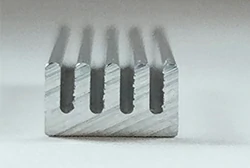

Advantages of extruded heat sinks

- The production process of extruded heat sinks is simple, and material costs are relatively low.

- Extruded heat sinks exhibit excellent thermal performance under medium to high airflow conditions.

- Extruded heat sinks have outstanding surface smoothness and appearance.

- Extruded heat sinks can easily undergo secondary processes such as anodizing, drilling, and welding.

- The cross-sectional design of extruded heat sinks provides omnidirectional heat conduction properties.

Given the comprehensive advantages of extruded heat sinks in terms of molds, performance, and manufacturing costs, we strongly recommend them as your preferred solution for thermal management. We also provide pin fin heat sink and other heat sink product, you can also check other heat sink solutions for your projects.Quick Quote

The most cost-effective manufacturing process for extruded heat sinks

- Heating the aluminum billet, which typically has a cylindrical or square shape, with the diameter or side length depending on the final dimensions of the heat sink profile.

- Extruding the billet by applying high pressure to extrude it from the mold, forming the desired shape of the heat sink profile.

- Cutting the extruded heat sink profile to the required length.

- To further enhance the mechanical properties of the heat sink profile, thermal treatment is often applied.

- Anodizing is typically performed to protect the surface of the heat sink profile from corrosion.

- Ensuring that the heat sink profile meets quality standards by conducting rigorous inspections.