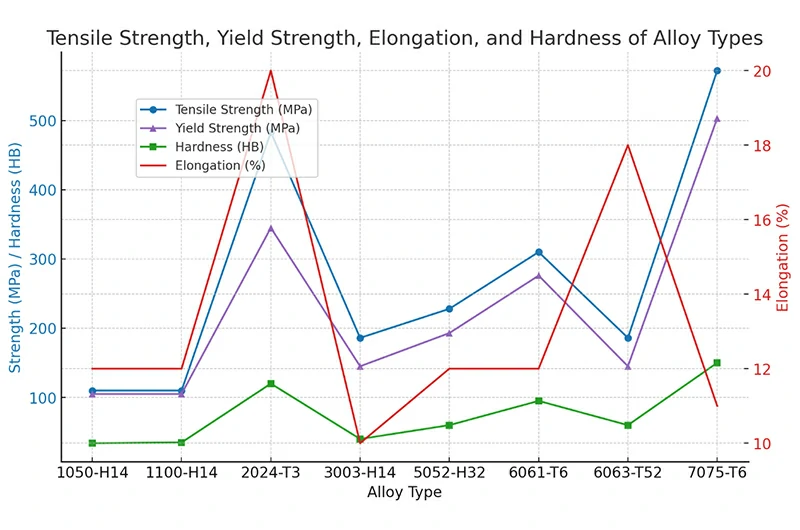

Alloy tempers and their best uses

| Alloy Temper | Features | Typical Uses |

| 6061-T6 | High strength, good corrosion resistance, easy to work with | Building structures, car frames, boat structures, pressure vessels |

| 6063-T52 | Good corrosion resistance, medium strength, easy to form and weld | Architectural decoration, frames, doors, windows |

| 7075-T6 | Very high strength, excellent fatigue resistance, lower corrosion resistance | Aerospace parts, high-performance bike frames, sports equipment |

| 5052-H32 | Good corrosion resistance, medium strength | Marine and transportation industries, boats, car manufacturing |

| 2024-T3 | High strength, good fatigue resistance | Aircraft and aerospace structures |

| 3003-H14 | Excellent corrosion resistance, easy to work with | Building roofs and walls, pipes, pressure vessels |

| 1050-H14 | Excellent electrical conductivity, good corrosion resistance | Electrical equipment, chemical equipment, reflectors |

| 1100-H14 | High flexibility, good corrosion resistance, easy to bend and form | Food packaging, chem |

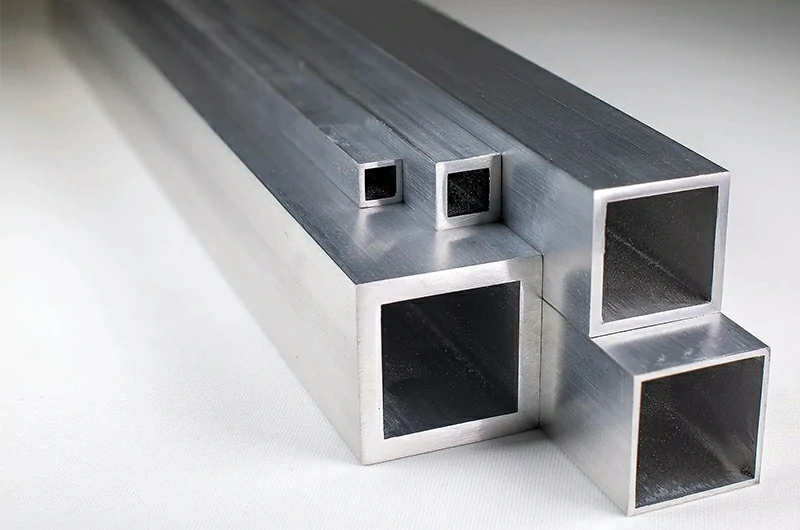

What wall thickness means for your project

When shopping for aluminum square tubing online, you might come across terms like "1/16 wall" and wonder what they mean.

It means that the walls are 1/16 of an inch thick.

Importance of Wall Thickness

Structural Integrity: Thicker walls provide greater strength and can handle heavier loads, ideal for structural applications.

Weight: Thinner walls result in lighter tubing, beneficial where weight matters.

Summary Table

| Wall Thickness | Application Suitability |

| 1/16 inch | Light-duty, decorative, framing, general purpose |

| 1/8 inch | Structural, heavy-duty |

| 3/16 inch | Structural, medium-duty |

| 1/4 inch | Heavy-duty structural, industrial |

| 3/8 inch | Extra heavy-duty, high-stress structures |

| 1/2 inch | Maximum load-bearing, industrial machinery |

Understanding the wall thickness is crucial.

Size of MASTAR square tube

Standard size

- 1/4" x 1/4"

- 3/8" x 3/8"

- 1/2" x 1/2"

- 5/8" x 5/8"

- 3/4" x 3/4"

- 7/8" x 7/8"

- 1" x 1"

- 1-1/4" x 1-1/4"

- 1-1/2" x 1-1/2"

- 1-3/4" x 1-3/4"

- 2" x 2"

- 2-1/2" x 2-1/2"

- 3" x 3"

- 4" x 4"

- 5" x 5"

- 6" x 6"

- 8" x 8"

- 10" x 10"

- 12" x 12"

Custom Sizes

Based on your specific needs, custom sizes are also available to fit any project requirement.

Give your project an edge with Mastar corner treatments

Sharp Corners

- Sharp corners give a clean, precise vibe, perfect for modern designs.

- Great for frames, supports, and decor that need a sharp, defined edge.

- Adds a crisp, polished touch to make your project pop.

Rounded Corners

- Rounded corners are smooth and reduce the chance of injuries from sharp edges.

- Ideal for public areas, playgrounds, and furniture where safety is key.

- Softens the look and boosts durability, making things last longer.

Need something unique? We’ve got custom corner treatments to fit your project’s exact needs.

Make your tubing shine with mastar surface treatments

Anodizing

- Vibrant Colors: Offer clear, black, gold, and more. Customer colors are available to achieve.

- Long Lengths: Anodized tubing up to 13 meters long, perfect for any project whether it's architectural, decorative, or industrial.

Anodizing Film Thickness: Uses and Benefits

| Film Thickness | Usage | Suitable Scenarios | Features |

| Thin Film (5-10 microns) | Best for decorative purposes and basic anti-corrosion protection | Indoor applications such as furniture, lighting fixtures, and decorative items | Provides a layer of anti-corrosion protection while enhancing the visual appeal of the aluminum surface |

| Medium Thickness Film (10-25 microns) | Suitable for outdoor use and situations requiring higher wear resistance | Perfect for building exteriors, outdoor facilities, and applications exposed to the elements | Offers improved weather resistance and durability, ensuring the aluminum maintains its appearance and structural integrity even in harsh conditions |

Anodizing not only boosts corrosion resistance but also enhances the visual appeal, giving the tubing a smooth, uniform finish with high adhesion and durability.

Powder coating

- Color Variety: Offers a wide range of colors, including standard shades like white, black, silver.

- Texture Options: Includes matte, satin, and textured finishes to enhance the feel and look of the tubing.

- Weather Resistance: Excellent UV and aging resistance, suitable for outdoor use, maintaining appearance and performance even under harsh conditions.

- Fast and Efficient: Quick application process, ideal for large-scale production to meet market demands efficiently.

- Customizable: Different coating thicknesses are available to suit various application needs.

Electrocoating (E-coating)

- Top-Notch Corrosion Resistance: Ideal for humid or corrosive environments like coastal, marine, and industrial settings.

- Smooth and Even Coating: Ensures uniform thickness, a smooth surface, and no drips or sags.

- Eco-Friendly: Uses water-based paints, meeting environmental standards and reducing harmful emissions.

- Color Variety: Available in standard colors like clear, black, gold, and customizable options based on client needs.

- Strong Adhesion: The coating sticks well, ensuring durability and stability during use.

Exploring more shapes of aluminum tubes in Mastar

In addition to square aluminum tubes, Mastar maintains a large inventory of aluminum tubes in various shapes. No matter what shape you need, feel free to contact us. We are committed to providing a one-stop shopping experience for your project needs.Quick Quote

Mastar Advantages

Building Contractors

Needs: Lightweight, high-strength, corrosion-resistant, and customizable materials to improve construction efficiency and structural stability.

Advantages:

- Lightweight and High-Strength: Mastar aluminum profiles weigh only 1/3 of steel with a tensile strength of up to 310 MPa.

- Corrosion Resistance: Ideal for harsh environments such as coastal constructions.

- Custom Services: Offers a wide range of specifications and customization options to meet diverse project needs.

- Case Study: Successfully applied in coastal commercial building projects, reducing maintenance costs by 20%.

References:

1.ASTM B221 Standard: Mechanical and chemical properties of aluminum profiles.

2."Aluminum Design Manual" by The Aluminum Association.

Home Decor Designers

Needs: Attractive, durable, and easy-to-process eco-friendly materials to achieve creative designs.

Advantages:

- Variety of Surface Treatments: Anodizing, electrophoresis coating, and more to meet aesthetic needs.

- High Hardness: Hardness up to 95 HB, strong durability.

- Easy to Process: Easy to cut and weld, suitable for complex designs.

- Case Study: Widely used in modern furniture and decorations, enhancing design flexibility and customer satisfaction.

References:

1."The Aluminum Finishing Guide" by Aluminum Anodizers Council.

2.ISO 7599:2018 Standard: Anodized coatings on aluminum and its alloys.

Manufacturing Purchasing Managers

Needs: Stable quality, timely supply, and cost-effective materials to ensure production efficiency and reduce costs.

Advantages:

- Quality Certification: ISO 9001 certified for stable quality.

- Timely Supply: Efficient production and logistics system ensure timely delivery.

- Cost-Effective: Prices are 10% lower than competitors.

- Case Study: Used by a major machinery manufacturer for high-precision equipment, significantly improving production efficiency.

References:

1.ISO 9001:2015 Quality Management System Certification.

2."Supply Chain Management" by Sunil Chopra.

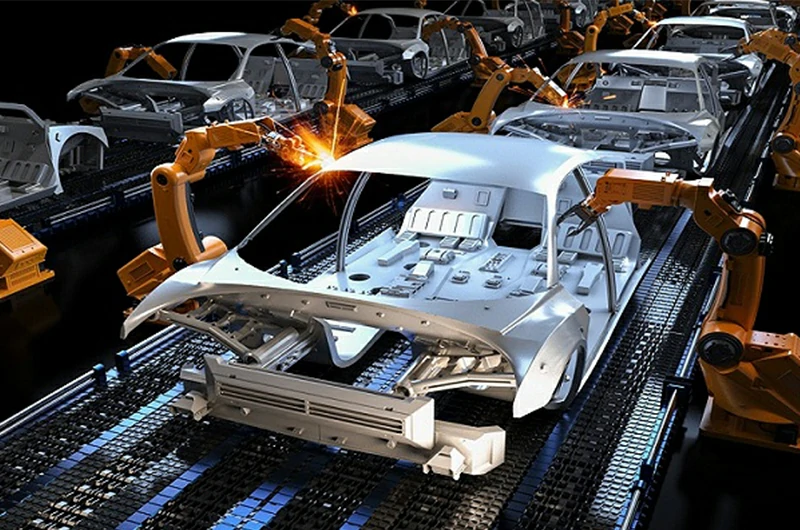

Automotive Manufacturers

Needs: Lightweight, high-strength, and corrosion-resistant materials to enhance vehicle performance and fuel efficiency.

Advantages:

- Lightweight and High-Strength: Weighs as little as 2.7 g/cm³, tensile strength up to 310 MPa.

- Corrosion Resistance: Excellent corrosion resistance extends vehicle lifespan.

- Performance Improvement: Applied in new car models, reducing body weight by 15% and improving fuel efficiency by 10%.

References:

1."Automotive Aluminum Joining Manual" by The Aluminum Association.

2."Materials Science and Engineering" by William D. Callister Jr.

Aerospace Engineers

Needs: Ultra-high-strength, lightweight, and durable materials to ensure flight safety and performance.

Advantages:

- Ultra-High Strength: Uses 7075-T6 alloy with a tensile strength of up to 570 MPa.

- Lightweight and Durable: Weighs as little as 2.81 g/cm³, very durable.

- Performance Enhancement: Successfully used in new aircraft structures, enhancing load capacity and range.

References:

1."Fundamentals of Aerospace Materials" by Alan A. Baker.

2."Introduction to Aerospace Materials" by Adrian P. Mouritz.

Refrigeration Equipment Manufacturers

Needs: High thermal conductivity, corrosion-resistant, and diverse materials to ensure efficient operation and long lifespan of equipment.

Advantages:

- High Thermal Conductivity: Thermal conductivity of 237 W/m·K.

- Corrosion Resistance: Excellent performance extends equipment lifespan.

- Performance Enhancement: Used in refrigeration equipment, improving efficiency by 20% and lifespan by 30%.

References:

1."Handbook of Aluminum" by George E. Totten.

2."Thermal Conductivity of Metals and Alloys" by C. Y. Ho.

Construction Engineering Consultants

Needs: Reliable, high-quality, and environmentally friendly materials to enhance the safety and quality of engineering projects.

Advantages:

- High-Strength and Eco-Friendly: Meets ASTM B221 standards with high strength and environmental properties.

- Wide Application: Recommended by multiple construction engineering consultant companies for high-demand projects, improving project quality and customer satisfaction.

References:

1.ASTM B221 Standard: Mechanical and chemical properties of aluminum profiles.

2."Sustainable Construction: Green Building Design and Delivery" by Charles J. Kibert.

Logistics Companies

Needs: Lightweight, high-strength, and durable materials to improve the efficiency and safety of transport equipment.

Advantages:

- Lightweight and High-Strength: Weighs as little as 2.7 g/cm³, tensile strength up to 310 MPa.

- Corrosion Resistance: Excellent performance reduces maintenance costs.

- Performance Enhancement: Applied in transport equipment, improving transport efficiency by 15% and reducing maintenance costs by 20%.

References:

1."Logistics & Supply Chain Management" by Martin Christopher.

2."Introduction to Logistics Systems Management" by Gianpaolo Ghiani.

Furniture Manufacturers

Needs: Attractive, lightweight, durable, and easy-to-process materials to meet diverse design needs.

Advantages:

- Excellent Surface Treatment: Hardness up to 95 HB, attractive and durable.

- Easy to Process: Suitable for various complex designs.

- Market Competitiveness: Widely used by furniture manufacturers in modern furniture design, enhancing market competitiveness.

References:

1."Furniture Design: An Introduction to Development, Materials and Manufacturing" by Stuart Lawson.

2."Wood & Furniture Coatings" by Franziska Müller.

Renovation Companies

Needs: Diverse, easy-to-install, and durable materials to improve renovation quality and efficiency.

Advantages:

- Variety of Specifications and Surface Treatments: Offers diverse options to meet different needs.

- Easy to Cut and Install: Convenient for construction, saving time.

- Corrosion Resistance: Excellent performance enhances durability.

- Customer Satisfaction Improvement: Used by renovation companies in high-end residential projects, improving construction efficiency by 20% and significantly enhancing customer satisfaction.

References:

1."The Complete Guide to Home Improvement" by Black & Decker.

2."Building Construction Illustrated" by Francis D.K. Ching.

Ready to make your project stand out? Contact us for more details on custom options and start your journey with Mastar aluminum square tubing today! Quick Quote