Extrudability refers to the ability of a material to be shaped under extrusion processing conditions. This term does not have a precise physical definition. The relative extrudability of aluminum alloys can be roughly measured by the extrusion exit speed.

- Generally, the higher the strength of the aluminum profile, the more difficult it is to extrude, resulting in a lower extrusion rate.

- Alloys that are easy to extrude can be processed at speeds of up to 100 m/min or faster.

- A typical extrusion ratio is 40:1, with the exit speed of more challenging alloys approximately 0.6-1.2 meters per minute.

- For alloys of medium difficulty or very challenging alloys, the temperature range between the extrusion load limit temperature and the unacceptable surface temperature is very narrow. As a result, hot extrusion techniques cannot significantly improve their extrusion performance.

Aluminum extrusion products

- Bars/Strips (Round, Square, Rectangular, Hexagonal)

- Tubes (Round, Square, Rectangular)

- Standard Profiles (Solid, Semi-Hollow, Hollow)

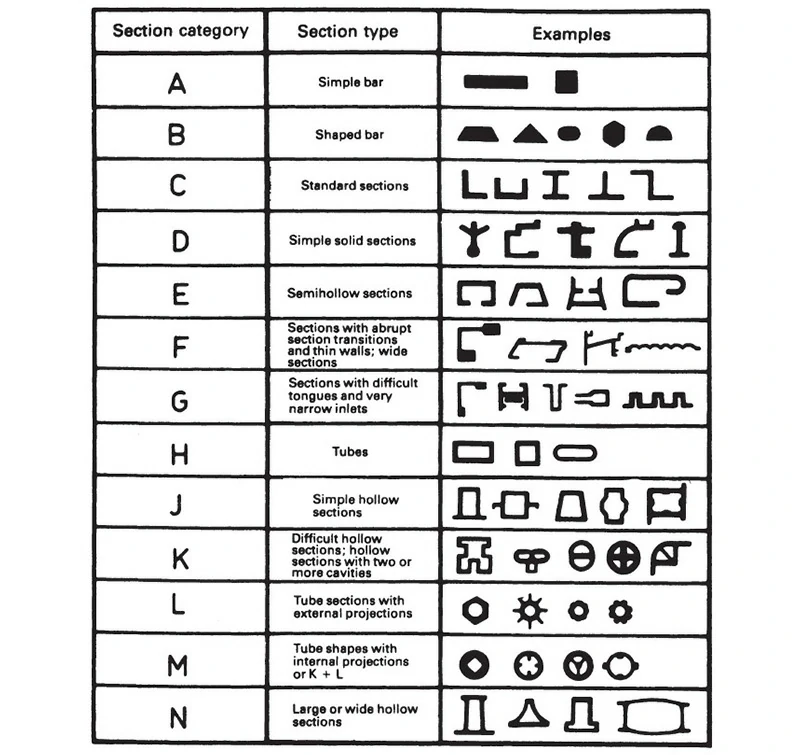

Classification by profile complexity

As the complexity of the profile cross-section increases, the extrusion pressure rises, and the exit speed decreases. The complexity of the profile is generally represented by the ratio of the profile's perimeter to its cross-sectional area or mass, known as the shape factor.

Assuming the extrudability of 6063 alloy bars is 100, all other alloys are compared with 6063. The smaller the number, the greater the difficulty.

| Alloy | Bars, Rods | Simple cross-section profiles | Complex cross-section profiles |

| 1050 | 200 | 160 | 120 |

| 3003 | 180 | 145 | 110 |

| 6063 | 100 | 90 | 80 |

| 7005 | 70 | 55 | 42 |

| 5052 | 60 | 50 | 40 |

| 2011 | 35 | 28 | 21 |

| 2024 | 18 | 14 | 11 |

| 7075 | 13 | 11 | 8 |

| 5456 | 10 | 8 | 6 |

Classification by extrudability and extrusion conditions

The extrudability of aluminum is reflected in metrics such as the required extrusion pressure, maximum extrusion speed, quality of the extruded product, yield rate, and die life. Factors affecting aluminum extrudability include:

- Alloy composition of the billet

- Casting structure of the billet

- Homogenization treatment and deformation resistance of the billet

- Temperature of the extrusion billet

- Temperature of the extrusion die and tooling

- Lubrication conditions

- Extrusion temperature and speed control technology

- Die structure

- Size of the die working zone

- Surface quality of the die working zone

- Control of metal flow in the die

| Alloy | Extrudability | Extrusion Temperature / ℃ | Extrusion Ratio | Exit Speed (m/min) | Split Flow Extrusion | Welded Extrusion |

| 1060, 1100 | 150 | 400-500 | 500 | 20-100 | Yes | Yes |

| 1200 | 125 | 400-500 | 500 | 25-100 | Yes | Yes |

| 2011 | 30 | 370-480 | 6-40 | 1.5-6 | No | No |

| 2014, 2017 | 20 | 370-480 | 6-40 | 1.5-6 | No | No |

| 2024 | 15 | 370-480 | 6-40 | 1.5-6 | No | No |

| 3003, 3004,3203 | 100 | 400-480 | 6-60 | 1.5-30 | Yes | Yes |

| 5052 | 60 | 400-500 | 6-50 | 1.5-30 | Difficult | No |

| 5056, 5083 | 25 | 420-480 | 6-50 | 1.5-10 | No | No |

| 5086 | 30 | 450-480 | 6-50 | 1.5-10 | No | No |

| 5454 | 50 | 450-480 | 6-50 | 1.5-10 | No | No |

| 5456 | 20 | 450-480 | 6-50 | 1.5-10 | No | No |

| 6061, 6151 | 70 | 450-520 | 30-60 | 1.5-30 | Yes | Yes |

| 6N01 | 90 | 460-520 | 30-80 | 15-80 | Yes | Yes |

| 6063, 6101 | 100 | 480-520 | 30-100 | 15-100 | Yes | Yes |

| 7001, 7178 | 7 | 430-500 | 6-30 | 1.5-5.5 | No | No |

| 7003 | 80 | 430-500 | 6-30 | 1.5-30 | Yes | No |

| 7075, 7079 | 10 | 360-440 | 6-30 | 1.5-5.5 | No | No |

According to the EN 755 tolerance standards

European standards

- EN 755-3 – Round Bars/Rods

- EN 755-4 – Square Bars

- EN 755-5 – Rectangular Bars/Rods

- EN 755-6 – Hexagonal Bars/Rods

- EN 755-7 – Seamless Tubes

- EN 755-8 – Window Tubes

- EN 755-9 – Profiles

These standards classify alloys into two categories based on the manufacturing difficulty of the products:

Group 1 – "Easy to Machine" Alloys

Group 2 – "Difficult to Machine" Alloys

Aluminum alloys with different extrusion difficulties as per EN 755-9

| Group 1 | 1000 series | EN AW-1050A, EN AW-1070A, EN AW-1200, EN AW-1350 |

| 3000 series | EN AW-3102, EN AW-3003, EN AW-3103 | |

| 5000 series | EN AW-5005, EN AW-5005A | |

| 6000 series | EN AW-6101A, EN AW-6101B, EN AW-6005, EN AW-6005A, EN AW-6106, EN AW-6008, EN AW-6010A, EN AW-6023, ENAW-6060, EN AW-6360, EN AW-6063, EN AW-6063A, EN AW-6463 | |

| Group II | 2000 series | EN AW-2007, EN AW-2011, EN AW-2011A, EN AW-2014, EN AW-2014A, EN AW-2017A, EN AW-2024, EN AW-2030 |

| 5000 series | EN AW-5019, EN AW-5049, EN AW-5051A, EN AW-5251, EN AW-5052, EN AW-5154A, EN AW-5454, EN AW-5754, EN AW-5083, EN AW-5086 | |

| 6000 series | EN AW-6012, EN AW-6014, EN AW-6018, EN AW-6351, EN AW-6061, EN AW-6261, EN AW-6262, EN AW-6262A, EN AW-6065, EN AW-6081, EN AW-6082, EN AW-6182 | |

| 7000 series | EN AW-7003, EN AW-7005, EN AW-7108, EN AW-7108A, EN AW-7020, EN AW-7021, EN AW-7022, EN AW-7049A, EN AW-7075 |

According to EN 755-3, aluminum alloys with different extrusion difficulties for bars and rods

| Group I | 1000 series | EN AW-1050A, EN AW-1070A, EN AW-1200, EN AW-1350 |

| 3000 series | EN AW-3102, EN AW-3003, EN AW-3103 | |

| 5000 series | EN AW-5005, EN AW-5005A, EN AW-5051A, EN AW-5251 | |

| 6000 series | EN AW-6101A, EN AW-6101B, EN AW-6005, EN AW-6005A, EN AW-6106, EN AW-6008, EN AW-6010A, EN AW-6012, EN AW-6014, EN AW-6018, EN AW-6023, EN AW-6351, EN AW-6060, EN AW-6360, EN AW-6061, EN AW-6261, EN AW-6262, EN AW-6262A, EN AW-6063, EN AW-6063A, EN AW-6463, EN AW-6065, EN AW-6081, EN AW-6082, EN AW-6182 | |

| GroupⅡ | 2000 series | EN AW-2007, EN AW-2011, EN AW-2011A, EN AW-2014, EN AW-2014A, EN AW-2017A, EN AW-2024, EN AW-2030 |

| 5000 series | EN AW-5019, EN AW-5049, EN AW-5052, EN AW-5154A, EN AW-5454, EN AW-5754, EN AW-5083, EN AW-5086 | |

| 7000 series | EN AW-7003, EN AW-7005, EN AW-7108, EN AW-7108A, EN AW-7020, EN AW-7021, EN AW-7022, EN AW-7049A, EN AW-7075 |