Aluminum extrusion is a process that pushes heated aluminum billets through a die opening to form specific shapes and sizes, leveraging the malleability and lightweight properties of aluminum to produce various aluminum alloy products.

Due to its strength, durability, lightweight, corrosion resistance, recyclability, and environmental benefits, extruded aluminum is widely used in automotive, aerospace, industrial profiles, and construction window and door applications.

By extrusion direction

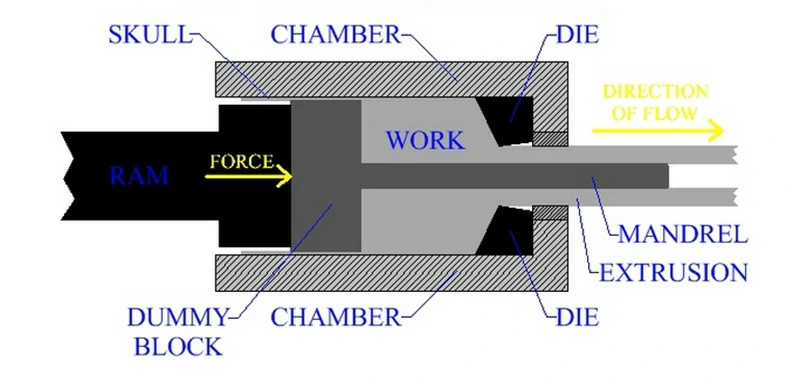

Direct extrusion (forward extrusion)

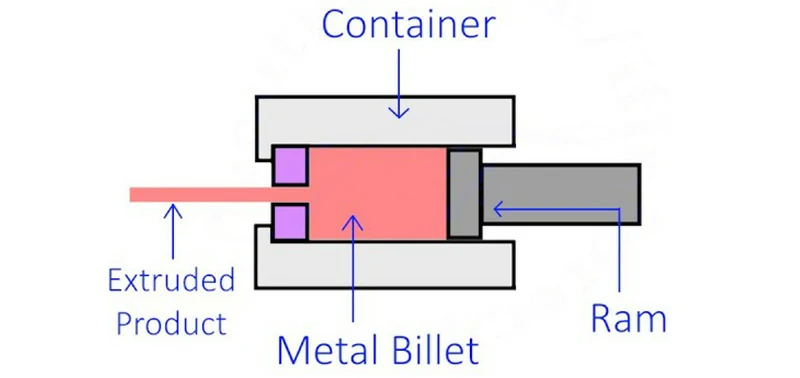

In direct extrusion, the aluminum billet is aligned with the extrusion direction, meaning the metal flow direction and the movement direction of the extrusion press are the same.

The advantages include simpler equipment and process, and ease of operation. However, it has higher friction and faster die wear.

- Suitable Alloys: 6061, 6063, 6082

- Applications: Window and door frames, curtain wall supports, radiators, bicycle frames, automotive parts

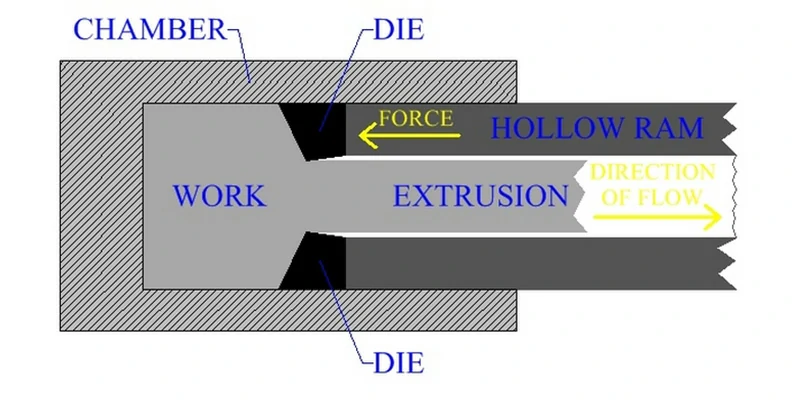

Reverse extrusion (backward extrusion)

In reverse extrusion, the aluminum billet is oriented opposite to the extrusion direction, meaning the metal flow direction is opposite to the movement direction of the extrusion press.

This method improves the surface quality of the extruded products and is suitable for producing high-precision aluminum profiles.

- Suitable Alloys: 6061, 6082, 7050, 7075

- Applications: Aircraft structural components, aerospace parts, high-precision automotive engine components, high-quality window and door frames

By deformation characteristics

Plane deformation extrusion

In plane deformation extrusion, the aluminum billet deforms primarily in a single plane.

- Suitable Alloys: 1050, 1100, 3003

- Applications: Cable shielding, radiators, aluminum foil, architectural decorative panels

Axisymmetric deformation extrusion

In axisymmetric deformation extrusion, the aluminum billet deforms around a symmetric axis. This method ensures the concentricity and symmetry of the products.

- Suitable Alloys: 2014, 2024, 6061

- Applications: Aircraft propellers, high-strength shafts, surgical instruments

General 3D deformation extrusion

In general 3D deformation extrusion, the aluminum billet deforms in three-dimensional space, suitable for producing complex-shaped aluminum profiles.

- Suitable Alloys: 6063, 6082, 7075

- Applications: Curtain wall supports, rail vehicle structural components, complex radiators

By lubrication state

Unlubricated extrusion (adhesive friction extrusion)

Extrusion is performed without lubrication, with direct contact between the aluminum billet and the die, resulting in high friction. This method is suitable for aluminum profiles with less stringent surface quality requirements.

- Suitable Alloys: 1060, 3003

- Applications: Simple structural profiles

Lubricated extrusion (conventional lubricated extrusion)

Lubricants are used to reduce friction, commonly employed for producing aluminum profiles with higher quality requirements.

- Suitable Alloys: 6061, 6063, 7075

- Applications: Automotive structural components, window and door profiles, aerospace structural components

Glass lubricated extrusion

Uses glass lubricants, suitable for producing high-temperature alloy aluminum profiles.

- Suitable Alloys: 2024, 7075

- Applications: High-temperature structural components

Ideal lubricated extrusion (hydrostatic extrusion)

Utilizes static liquid lubrication for near-zero friction extrusion, suitable for producing high-precision aluminum profiles.

- Suitable Alloys: 6061, 7075

- Applications: High-precision medical instruments, precision radiators, high-precision structural components

By extrusion temperature

Cold extrusion

Extrusion is performed at room temperature, suitable for producing high-strength and high-precision aluminum profiles. The material requirements for the aluminum billet are high, and there is a risk of cracking.

- Suitable Alloys: 7075, 2024

- Applications: Aerospace high-strength connectors, high-precision automotive parts, high-strength industrial shafts

Warm extrusion

Extrusion is performed at intermediate temperatures, suitable for aluminum profiles requiring both strength and ductility.

- Suitable Alloys: 6061, 6082

- Applications: Window and door frames, medium-strength industrial profiles, electronic radiators

Hot extrusion

Extrusion is performed at high temperatures, suitable for producing complex cross-sectional aluminum profiles. High temperatures enhance material plasticity, suitable for large and complex aluminum profile production.

- Suitable Alloys: 6063, 7075

- Applications: Complex building profiles, vehicle body structural components, large industrial structural components

By extrusion speed

Low-Speed extrusion (conventional extrusion)

Extrusion speed is relatively slow, suitable for fine processing and high-precision aluminum profiles.

- Suitable Alloys: 6061, 6063

- Applications: Automotive frames, rail transit components, window and door profiles

High-Speed extrusion

Extrusion speed is fast, suitable for mass production with high efficiency, but requires advanced equipment and molds.

- Suitable Alloys: 6061, 7075

- Applications: Large-scale window and door profiles, large-scale structural components, large-scale vehicle body parts

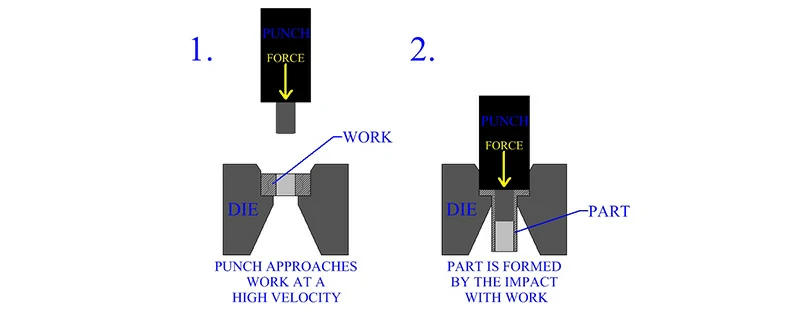

Impact extrusion (ultra-high-speed extrusion)

Extrusion speed is extremely fast, using instantaneous impact force for extrusion, suitable for producing ultra-thin and ultra-fine aluminum profiles.

- Suitable Alloys: 2024, 7075

- Applications: Ultra-fine heat sinks, precision surgical instruments, lightweight high-strength components

By die type or die structure

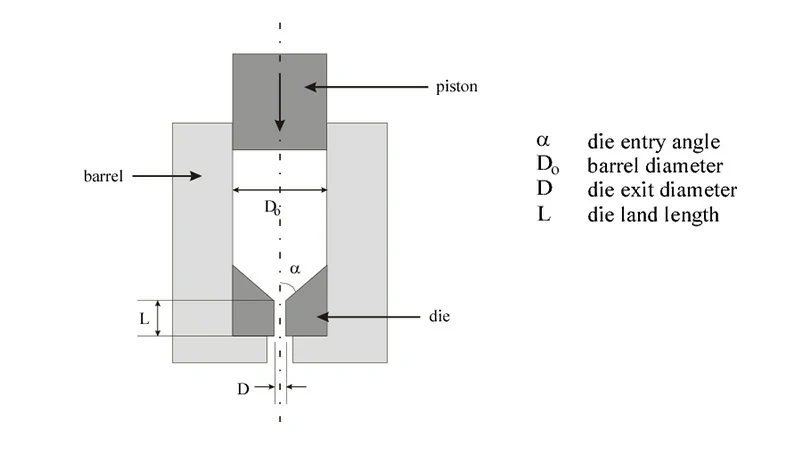

Flat die extrusion

Uses flat dies, suitable for producing simple cross-sectional aluminum profiles.

- Suitable Alloys: 6061, 6063

- Applications: Standard profiles

Conical die extrusion

Uses conical dies, suitable for producing tapered and gradient cross-sectional aluminum profiles.

- Suitable Alloys: 6061, 6082

- Applications: Tapered profiles, gradient structural components

Split flow combination die extrusion

Uses combination dies for split flow, suitable for producing complex cross-sections and multi-porous aluminum profiles.

- Suitable Alloys: 6063, 7075

- Applications: Multi-porous radiators, complex vehicle body structural components

Die with piercing needle extrusion

Dies with piercing needles, suitable for producing hollow and special structure aluminum profiles.

- Suitable Alloys: 6061, 6063

- Applications: Hollow profiles, tubes

By shape or number of billets

Round billet extrusion

Uses round billets, suitable for producing aluminum profiles with circular cross-sections.

- Suitable Alloys: 6061, 7075

- Applications: Standard profiles, brackets and frames, axles

Flat billet extrusion

Uses flat billets, ideal for producing aluminum profiles with flat and wide cross-sections.

- Suitable Alloys: 6063, 2024

- Applications: Wide section profiles, flat structural components, wide heat sinks

Multiple billet extrusion

Uses multiple billets simultaneously, suitable for multi-station and high-output production methods.

- Suitable Alloys: 6061, 6063

- Applications: Batch profile production

Composite billet extrusion

Uses composite billets of different materials, suitable for producing aluminum profiles with special properties.

- Suitable Alloys: Various alloy combinations

- Applications: Composite material structural components

By shape or number of products

Rod extrusion

Produces rods of various cross-sections, suitable for construction and industrial use.

Suitable Alloys: 6061, 7075

Applications: Standard profiles, brackets and frames, axles

Tube extrusion

Produces tubes of various cross-sections, widely used in transportation and structural fields.

Suitable Alloys: 6061, 6063

Applications: Hollow profiles, transportation pipes, lightweight structural tubes

Solid profile extrusion

Produces profiles with solid cross-sections, suitable for applications requiring high strength.

Suitable Alloys: 6061, 7075

Applications: Load-bearing beams, support columns, axles, structural components, mechanical parts, tools

Hollow profile extrusion

Produces profiles with hollow cross-sections, suitable for lightweight and structural optimization needs.

Suitable Alloys: 6063, 6082

Applications: Hollow window frames, curtain walls, bicycle frames, automotive frames, transportation pipelines, frame structures

Variable section profile extrusion

Produces profiles with variable cross-sections, suitable for complex structural applications.

Suitable Alloys: 6061, 7075

Applications: Decorative profiles, structural beams, complex body structures, variable heat sinks, frames

Single product extrusion (single die extrusion)

Uses a single die to produce a single product, suitable for small batch and high precision production.

- Suitable Alloys: 6061, 7075

- Applications: Precision surgical instruments, high-precision heat sinks, high-strength connectors

Multiple product extrusion (multiple die extrusion)

Uses multiple dies to produce multiple products simultaneously, suitable for large batch production.

- Suitable Alloys: 6063, 7075

- Applications: Mass production of window frames, standard profiles, large batch automotive components

By equipment type

Vertical extrusion

Uses vertical equipment, suitable for producing shorter aluminum profiles.

- Suitable Alloys: 6061, 6063

- Applications: Short profiles, decorative strips, precision mechanical parts, small heat sinks

Horizontal extrusion

Uses horizontal equipment, suitable for producing longer aluminum profiles.

- Suitable Alloys: 6061, 6082

- Applications: Long beams, long columns, long profiles for rail transportation, long rods, pipes

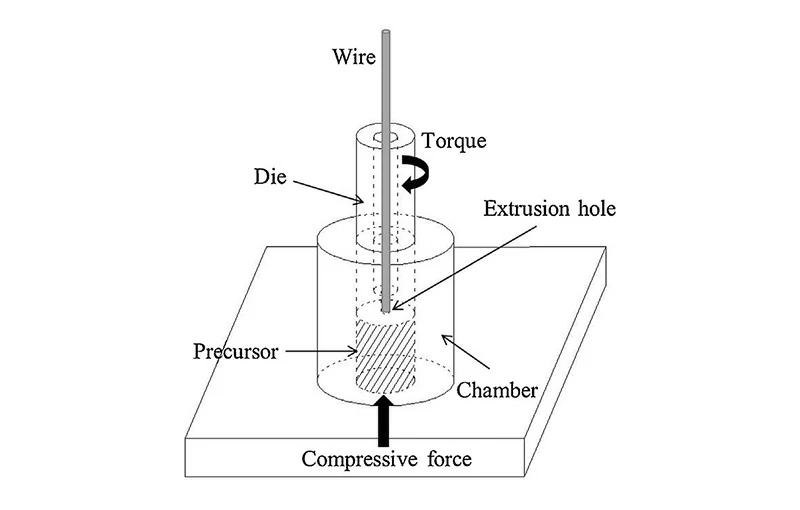

Conform continuous extrusion

Uses continuous extrusion equipment, suitable for high-volume, continuous production.

- Suitable Alloys: 1050, 6061

- Applications: Cable sheathing, conductive tracks, long profiles, continuous profile production