- The different meanings of Section Profile Extrusion and Frames

- Aluminum profiles product classification

- Aluminum profiles applications

- Aluminum profiles surface treatments and colors

- Aluminum profiles production processes

- Extrusion types of aluminum profiles

- Aluminum profiles features

- Aluminum profiles common alloys

- The cost of aluminum profiles depends on several factors

- How to choose a reliable aluminum profile supplier

Aluminum extrusion, also known as aluminum frames, refers to aluminum products of various shapes produced through the aluminum extrusion process.

This material undergoes extrusion and heat treatment processes, resulting in various complex deformations.

Aluminum profiles are widely used in fields such as construction, transportation, machinery, electronics, and power due to their advantages of being lightweight, high-strength, corrosion-resistant, recyclable, and easy to process.

The different meanings of Section Profile Extrusion and Frames

"Section" refers to the cross-sectional shape of aluminum profiles, including dimensions and geometric shapes of both inner and outer surfaces.

"Profile" emphasizes the overall shape and form of aluminum profiles, including the cross-sectional geometry (section) and longitudinal shape.

"Extrusion" emphasizes the manufacturing process of transforming aluminum into shaped profiles.

"Frames" refer to structures or components constructed using aluminum profiles. These frames serve as the skeleton framework for various applications such as windows, doors, furniture, and machinery.

Aluminum profiles product classification

Standard section aluminum profiles

- T slot

T-slot structural framing is a framework system made of rectangular 6105 aluminum.

- U profile

The U-profile features an inner radius angle, suitable for structural applications requiring high strength.

- T profile

The T-profile is most commonly used in structural applications. It is typically extruded from alloys 6063 and 6061.

- Z profile

6063 and 6061 are extruded into Z-profiles, which are highly suitable for architectural decoration, door and window frames.

- H section

H section features inner radius angles and is often treated with milled or anodized surface finishes.

- F channel

The F channel has an "F" shaped cross-section with an internal protruding rib.

- Corner profile

The corner profile is used for LED lights and is often installed in plasterboards and walls.

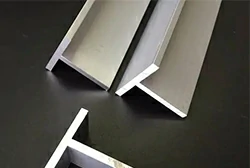

- Angle aluminium

Angle aluminum is suitable for structural applications that require high strength. The alloy grade is 6063-T6.

- J profile

J-profile is a versatile profile that can be used for door handles, edging, wall edges, and flooring.

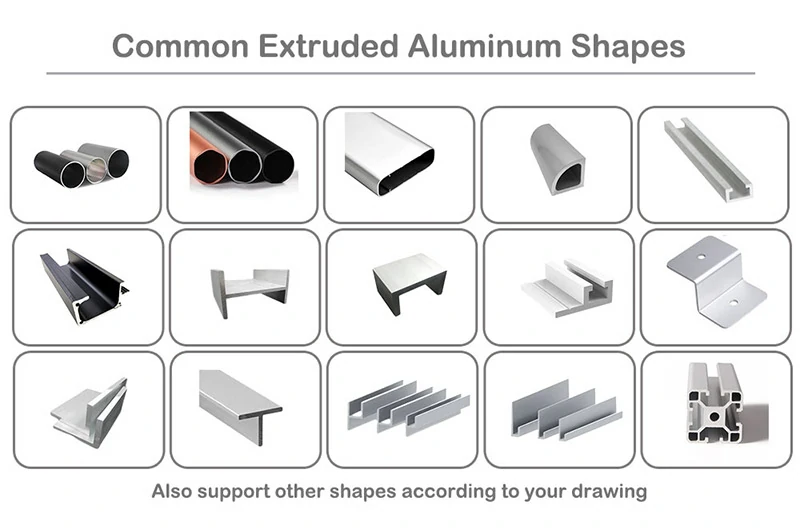

Special section aluminum profiles

The shapes are endless, with a variety of size options.

- Aluminium window profiles

- Aluminium door profile

- Aluminum enclosure extrusions

- 3d printer aluminum extrusion

- Aluminum hinge extrusion

- Aluminium nut profile

- Aluminium profile for kitchen

- Aluminium extrusion heat sink

- Aluminium LED extrusion

Tube, rod, and bar aluminum profiles

- Aluminum round tube

- Aluminum square tube

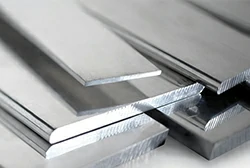

- Aluminum flat bar

- Aluminum round rod

- Aluminum square bar

- Aluminum hexagonal rod

Aluminum profiles applications

- Curtain walls, ceilings, door frames, windows.

- Parts for 3D printers, conveyor belts, CNC machine frames, radiators, automation equipment components, mechanical housings, elevator parts, shelves, injection molds.

- Kitchen profiles, pressure vessels, wall-mounted frames, ladders, beds, display cabinets, curtain rods, aluminum furniture, awnings, bicycle frames, ski pole bodies.

- External hard drives, power supply enclosures, TV housings, monitor enclosures.

- Wind turbine tower frames, solar panel frames.

- Vehicle frames, traffic signal lights, street light brackets.

- Aircraft structural components, spacecraft parts, aircraft fuel tanks, oil pipes, aluminum components for vehicles and ships, instruments.

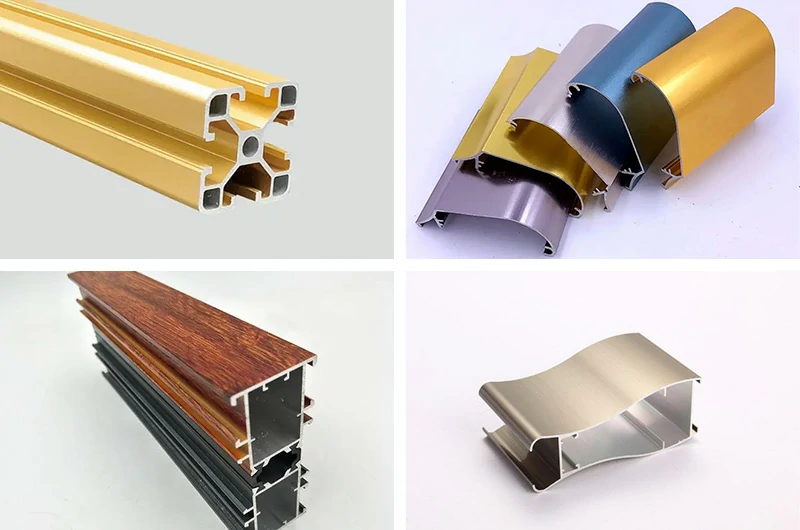

Aluminum profiles surface treatments and colors

Aluminum alloy profiles have various surface treatment methods, such as anodizing, electrophoretic coating, and powder coating, which can significantly enhance their corrosion resistance, wear resistance, and aesthetic appeal.

- Electrophoresis aluminum profile, silver-white or gray, with a metallic texture.

- Powder coated aluminum profile, white, black, gray, red, blue, etc.

- Fluorocarbon paint aluminum profile, gold, copper, black, white.

- Wood grain effect aluminum profile, wood grain texture effect, cherry wood color, walnut color, etc.

- Polishing aluminum profile, silver, shiny metallic color.

- Brushing aluminum profile, brushed texture, usually silver-gray or gray.

- Shiny aluminum profile, highly reflective mirror-like surface.

- PVDF profiles.

Aluminum profiles production processes

1.Heating aluminum blocks or aluminum alloys to a molten state, then injecting the molten aluminum into molds through casting to form preliminary aluminum billets.

2.Heating the cast aluminum billets to an appropriate temperature, then extruding them into the desired cross-sectional shapes, such as round, square, rectangular, etc., using extrusion machines, forming the final aluminum profiles.

3.Pre-treating the surface of aluminum profiles, then performing anodizing, powder coating, fluorocarbon paint coating, wood grain transfer printing, etc., according to customer requirements.

4.Cutting the extruded aluminum profiles to the desired lengths and precision to meet tolerance requirements.

5.Drilling, milling, cutting, stamping, welding, bending, assembling, CNC machining the cut aluminum profiles.

6.Customizing professional packaging solutions for aluminum profiles according to customer needs.

Extrusion types of aluminum profiles

Aluminum alloy extrusion methods include Direct extrusion and Indirect extrusion.

Direct extrusion is the simplest production mode. In it, the die is stationary while the ram forces the billet through the die opening. The action of the billet and ram moving forward in the same direction has led to this method being called the forward or direct aluminum extrusion process. Direct extrusion is the simplest production mode, with the die stationary while the ram forces the billet through the die opening.

Indirect extrusion is a process in which the billet remains stationary, but the assembly on the end of the ram moves against the billet. It enables the pressing of harder alloys (2xxx, 7xxx) and products with smaller cross-sections due to the smaller extrusion pressures. Lower pressures also allow for lower pressing temperatures and consequently greater extrusion speed. This of course increases productivity.

Aluminum profiles features

- Aluminum is easily processed and cast into various shapes and structures.

- It is a good electrical conductor, suitable for electrical and electronic fields.

- Aluminum can be recycled multiple times without losing its performance and integrity.

- It is non-magnetic, suitable for applications sensitive to magnetism.

- Processing aluminum consumes low energy, helping to reduce production costs and environmental burdens.

- It has a high strength-to-weight ratio, providing good load capacity.

- Aluminum exhibits good corrosion resistance, suitable for outdoor and humid environments.

- It has good thermal conductivity, suitable for applications with high heat transfer requirements.

Aluminum profiles common alloys

| Alloy | preservative | intensity | extrusion | welding |

| 1050 | excellent | Low | excellent | excellent |

| 1100 | excellent | Low | excellent | excellent |

| 2024 | medium | excellent | medium | medium |

| 3003 | medium | medium | medium | medium |

| 5052 | excellent | medium | medium | medium |

| 6061 | medium | medium | excellent | medium |

| 6063 | medium | medium | excellent | medium |

| 6105 | medium | medium | excellent | medium |

| 7075 | medium | excellent | Low | Low |

The cost of aluminum profiles depends on several factors

- The price difference between different aluminum alloy grades can be significant.

- Larger size specifications of aluminum profiles typically result in higher prices.

- Different surface treatment processes for aluminum profiles also lead to price variations. Anodized aluminum profiles are generally more expensive than painted ones.

- The price of aluminum profiles is influenced by market supply and demand dynamics.

- Bulk purchases in large quantities often result in better price discounts.

How to choose a reliable aluminum profile supplier

There are many different aluminum suppliers in the market, each offering varying product sizes, shapes, and prices. Therefore, choosing a suitable supplier is crucial.

As a reputable aluminum profile supplier, Mastar Metal provides top-quality products to global customers.

- Mastar Metal's products can be shipped to locations worldwide, whether you are in the United States, Europe, South America, you can easily receive our products.

- Mastar Metal provides high-quality products and services, with prices that are absolutely competitive.

- Mastar Metal offers customized solutions and branding services.

- Mastar Metal has a professional team that guarantees feedback within 24 hours.

- Mastar Metal has ample inventory and a variety of mold sizes, providing you with fast delivery services.

- Mastar Metal provides samples and sends them.