Aluminum trim profiles are versatile materials extensively used in architectural decoration due to their lightweight, corrosion resistance, and ease of fabrication, making them preferred choices for designers and architects.

These aluminum trim profiles come in various shapes and styles, including T, U, C, H, F, J, catering to diverse project needs. Whether for interior decor or outdoor construction, aluminum trim profiles enhance aesthetics, functionality, and durability of buildings, ensuring excellent sustainability.

Mastar Popular Aluminum Decorative Profiles Product List

Aluminum angles are lightweight, high-strength aluminum profiles used in construction and industrial applications, known for their corrosion resistance. They are categorized into equal angle aluminum and unequal angle aluminum based on their side lengths. Commonly used alloys include 6061 and 6063, with dimensions ranging from 10-100mm in side length and 1-5mm in thickness. Available finishes include polished, anodized, and powder coated.

T-bars are lightweight, high-strength aluminum profiles used in construction and industrial applications. They are commonly used in display cabinets, glass mirror frames, connectors, and decorative trim. T-bars are classified into Rounded Inside T-Bar (structural support) and T-Bar (architectural decoration) based on their corner angles. Common alloys used are 6061 and 6063, with various customizable finishes available.

Aluminum U-channels are lightweight, corrosion-resistant materials used in construction and decoration, commonly applied on walls, ceilings, door and window frames, etc. We offer square and round outer channels. Commonly used alloys include 6061 and 6063, with options for anodized, electrophoretic paint, and powder coated finishes.

Aluminum C-Channel

C-channels, also known as sliding track channels, are widely used architectural profiles for applications such as sliding door tracks, glass door slides, curtain tracks, etc. Typically made from alloy 6063-T5, they are available in various lengths and can be customized to meet specific customer requirements with a range of common finishes.

Aluminum H-channels, also known as extruded aluminum dividers and divider bars, are used in both construction and industrial applications. They come in single and double divider configurations for applications including frames, signage, tile separators, partition boards, and decorative frame dividers. Known for their lightweight, high strength, and corrosion resistance, they are versatile in design and function.

Z-Clip and Z-Bar is a Z-section aluminum profile for fixing and installation. We can supply Z-clip fastener, cleated bar, smooth rail, and Z bar. Its design allows the components to interlock quickly. It is commonly used for hanging installation of wall panels, partitions, borders and decorative strips. Hot selling sizes are 3/8″ lift off, 5/8″ lift off, 1-1/2″ wide, 2″ wide, 3″ wide, 1/4″ standoff or 3/16″ standoff.

J-Channel, also known as J-Cap, J Edge Trim, J Moulding or Mirror J Cap, is a structural edge used for architectural decorative parts, commonly used in mirror/glass frames, edge trim strips, store fixtures, etc. There are rich finishes, anodizing, brushing, powder coating, electrophoresis, gold, bronze and many other finishes to choose from.

Z-Clip and Z-Bar are aluminum profiles with a Z-shaped cross-section used for fastening and installation. We offer Z-clip fastener, cleated bar, smooth rail, and Z bar, designed for quick interlocking of components. These profiles are commonly used for mounting wall panels, partition hanging installations, framing, and decorative trim. Popular sizes include 3/8″ lift off, 5/8″ lift off, 1-1/2″ wide, 2″ wide, 3″ wide, 1/4″ standoff, or 3/16″ standoff.

I Shape Aluminum

Aluminum J-Channel, also known as J-Cap, J Edge Trim, J Moulding, or Mirror J Cap, is a structural edge used for architectural decorations. It is often used for mirror/glass frame edges, edge trim, and store fixture installations. Available in various finishes including anodizing, brushed, powder coating, electrophoresis, gold, and antique bronze.

Aluminum F Channel, also known as corner mouldings, is commonly used for building roof edges, stair tread edges, and cabinet manufacturing. It is versatile in application, flexible in design, and available in sizes such as 3/4″, 1/4″, and 5/16″. Lengths can be customized, and it is available in common finishes or can be customized based on customer requirements.

Mastar's Comprehensive Solutions in Architectural Decorative Aluminum Profiles

Aluminum Threshold

Aluminum Threshold- Mastar offers a range of extruded aluminum thresholds for transitions between tiles, wood floors, and carpets. Durable and easy to clean, they include options like carpet binder bars, trims, tile bars, stair nosings, and customizable thresholds, ideal for modern spaces.featuring diverse finishes and customizable lengths.

Aluminum Slatwall Inserts

Aluminum Slatwall Inserts- Slatwall inserts are aluminum strips installed on slatwall panels to support and reinforce their structure, providing channels or slots for hanging displayed items. They are commonly used in retail stores, showrooms, or offices. Standard lengths are 4, 8, or 12 feet, customizable to fit various project styles.

Aluminium Sliding Channel

Aluminium Sliding Channel- Aluminum Slide Track Channels, also known as Aluminum C/T slide track channels, are widely used in applications like glass display cases, sliding track display cases, cabinet door tracks, and custom shelving units. Mastar's aluminum C-channel is easy to cut, shape, or weld, enhancing projects with its refined aesthetics.

Price Tag Channel

Price Tag Channel- Aluminum Price Tag Channel (Ticket Moulding or Price Tag Moulding) offered by Mastar is available in various lengths, designed to easily clip onto metal shelves. It provides convenient installation, easy maintenance, and cleaning, suitable for retail shelves, storage rooms, and laundry areas. Ample stock, rich finishes, custom cut to length.

Aluminum Pull Handles

Aluminum Pull Handles- Mastar offers a variety of aluminum pull handles for drawers, cabinets, sideboards, and wardrobe doors. These extruded handles come in various shapes such as F, L, C, and J-type, suitable for different project requirements.Ample stock, quick delivery, customizable lengths, multiple finish options.

Aluminum Handrails & Fencing

Aluminum Handrails & Fencing- Mastar provides extruded aluminum components for fences and handrails, such as glass railing extrusions, round tubes, square tubes, D-shaped tubes, Balustrade Capping, and Side Mount Channel. These are widely used in stairway guardrails, glass partitions, balcony or deck railings, and traffic barriers. They offer multiple finish options and customizable lengths.

Aluminium Corner Guard

Aluminium Corner Guard- Aluminium Corner Guard, also known as Aluminium Corner Protectors, is used to safeguard walls and corners from damage caused by large equipment movement. Widely used in commercial settings like kitchens, supermarkets, hospitals, parking lots, and loading docks.

Aluminum Awning Frames

Aluminum Awning Frames- Extruded aluminum awning components typically include awning tracks, awning pipes, and square tubes with flanges, prized for their resistance to stress cracking, high corrosion resistance, and favorable strength-to-weight ratio. Widely used atop building doors and windows, canopies, and camper van roofs, they are the perfect choice for awning projects.

Aluminium Skirting

Aluminium Skirting- Aluminium skirting boards (including LED aluminium skirting and flat aluminium skirting) are essential for modern floors, known for their easy installation, moisture and corrosion resistance. They bridge gaps between floors and walls, combining practicality and aesthetics. Available heights include 4cm, 6cm, 8cm, and 10cm, with various colors and finishes to choose from.

Aluminum Curtain Track

Aluminum Curtain Track- Aluminum curtain track systems are widely used in residential and commercial applications, ideal for window decorations, privacy partitions, and particularly suitable for hospital ward privacy dividers. Mastar offers a variety of aluminum curtain tracks with multiple finish options to meet your project needs, providing versatile and durable solutions.

Aluminum Curtain Rod

Aluminum Curtain Rod- Aluminum curtain rods are ideal for modern home decor, offering excellent corrosion resistance and strength. They are suitable for various environments like living rooms, bedroom windows, and simple bathroom partitions. With sleek designs and diverse colors and finishes, they meet a wide range of decoration needs with diameters typically ranging from 25-35 cm.

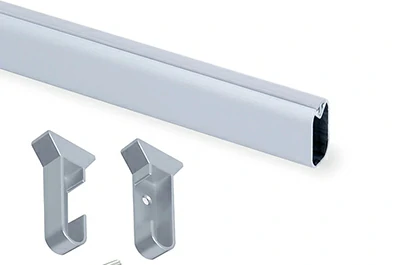

Aluminium Wardrobe Rail

Aluminium Wardrobe Rail- Aluminum wardrobe rails are the ideal choice for modern closet storage systems. Mastar's elliptical-shaped aluminum rails are more durable than traditional round rails. They are easy to install and suitable for most cabinets, wardrobes, towel racks, and napkin holders. Customizable lengths available, multiple finishes to choose from.

LED Strip Aluminium Profile led

LED Strip Aluminium Profile led- LED strip aluminum profiles, also known as mounting channels, offer a modern solution for installing LED light strips. Mastar provides square, winged, and 90-degree angle profiles to meet diverse preferences and applications. They protect LED strips 8-10 millimeters wide, ideal for lighting in wardrobes, shelves, display cabinets, and under cabinets.

Aluminium Stair Nosing

Aluminium Stair Nosing- Aluminium Stair Nosing is typically installed along the edges of stairs to enhance aesthetics, reduce wear, and prevent accidental slips. It offers durability and is easy to clean, suitable for indoor and outdoor stair steps, as well as for use as edge trim on tabletops, countertops, shelves, and other surfaces.

What surface treatments are available for Mastar's aluminum decorative profiles?

Mechanical Processing

Mechanical processing is a key step in enhancing the appearance of aluminum, including methods such as sandblasting, grinding, polishing, and buffing. These techniques can create smooth, rough, or chrome-plated surfaces, enhancing the aesthetic appeal and texture of the aluminum. Among these methods, polishing is the most commonly used to highlight the texture and gloss of extruded aluminum components, enhancing their visual quality.

- Sandblasting: Adjusts surface smoothness or roughness while removing potential contaminants.

- Grinding: Removes material using rotating abrasive tools to achieve desired tolerances.

- Polishing: Highlights the texture, gloss, and appearance of aluminum extrusions, creating a mirror-like finish.

- Buffing: Uses lightweight abrasives to improve the surface appearance of aluminum decorative components.

Pre-treatment Processes

Pre-treatment involves cleaning before coating, typically through chemical or electrolytic processes, commonly using chemical methods. It prevents surface contamination on aluminum, forming a barrier layer that enhances coating adhesion and corrosion resistance. While pre-treatment is just one part of aluminum processing, its role is crucial. Acid or alkali etching and cleaning of aluminum surfaces ensure that coatings or paints adhere firmly.

Anodizing

Anodizing is an electrochemical process used to enhance the appearance and durability of aluminum decorative profiles. Immersing aluminum profiles in an acidic electrolyte bath maintains their metallic luster and imparts durable, vibrant colors. The corrosion-resistant coating formed during this process makes anodized aluminum profiles highly suitable for various applications. Furthermore, the surface after anodizing becomes an integral part of the substrate, preventing peeling or flaking and allowing for additional surface coatings as needed. Our anodized aluminum finishes are available in multiple colors, detailed as follows:

Powder Coating

Powder coating is a durable decorative surface treatment material that outlasts traditional paint. Similar to painting, powder coating requires pre-treatment of aluminum decorations. By melting dry plastic powder onto metal surfaces, it creates textured, matte, or glossy coatings. Mastar offers a variety of colors in powder coating processes suitable for aluminum decorations. Powder coating provides additional protection against corrosion, wear, and weathering for decorative elements.

Polyvinylidene Fluoride(PVDF)

PVDF coating is often confused with powder coating but differs significantly. PVDF is a resin-based liquid coating, whereas powder coating uses electrostatically charged powder. PVDF coatings are more durable than powder coatings, but the latter is more robust. Both require baking aluminum profiles with the coatings to ensure strong adhesion.

Sublimation

Sublimation is a transfer printing process where a thin film with a pattern wraps around profiles. By heating, the pattern is directly transferred onto extrusions, creating a permanent bond with aluminum decorations. This method can mimic wood grain and other surface patterns. Sublimation technology makes aluminum profiles resemble wood and is a rapidly growing and popular surface treatment method.

Different types of surface treatments vary in cost. Anodizing is the most expensive due to its excellent corrosion resistance and durability, suitable for demanding environments. Powder coating and PVDF coatings are also common choices: powder coating is known for its robustness, while PVDF coatings offer longer-lasting protection. When choosing specific finishes, it's essential to consider both budget and the environment where the aluminum decorations will be used to ensure optimal performance and cost-effectiveness.

What are the commonly used aluminum alloy grades for Mastar's aluminum decorative profiles?

Mastar commonly uses aluminum alloys from the 6000 series for manufacturing extruded aluminum profiles. This series includes alloys such as 6063, 6061, 6005, 6082, and 6060. By adding magnesium and silicon, these alloys exhibit good elasticity and can be heat-treated, making them widely used in the production of aluminum profiles. Among them, the most commonly used are alloys 6063 and 6061.

6063

Alloy 6063 is a medium-strength material suitable for extrusions, particularly for structures with thin walls and small shapes. Its glossy surface makes it an ideal choice for architectural projects due to its high tensile strength, excellent machinability, and superior corrosion resistance. It is known as an architectural alloy. The increased silicon and magnesium content enhances its fluidity and durability. It can be welded and brazed, cold-worked, and shaped. It is also suitable for processes like anodizing, polishing, and powder coating, creating bright, protective, and vibrant coatings.

6061

Alloy 6061 is similar to 6063 but offers higher strength, excellent corrosion resistance, stress resistance, crack resistance, good formability, and weldability. It is used for structural applications and shares similar weldability, corrosion resistance, and coating properties with 6063. However, compared to 6063, 6061 requires more force and careful handling for cold forming.

What are the optimal characteristics of aluminum decorative profiles?

- Easy installation: Installation should be simple and achievable without specialized knowledge.

- Durable: Long-lasting durability reduces maintenance and replacement costs.

- Strong and tensile: Sufficient strength to withstand extreme conditions and impacts, extending lifespan.

- Excellent finish: High-quality surface treatment enhances aesthetic value and provides effective protection.

- Cost-effective: Should be budget-friendly at purchase and deliver value-for-money performance.

Common Q&A

Q: What are the common alloys for aluminum decorative components?

A: Common alloys for aluminum decorative components include but are not limited to 6061, 6063, 6005, 6082, and 6060.

Q: What is the hardness of extruded aluminum profiles?

A: Depending on the grade, the strength of aluminum alloys can reach up to five times that of steel.

Q: What are the common thicknesses?

A: Aluminum decorative components come in a wide range of thicknesses, typically from 0.9mm to 3.0mm.

Q: Why is precision machining important for aluminum decorative components?

A: Precision machining enhances the corrosion resistance and improves the appearance by allowing for the selection of suitable surface finishes to achieve the best aesthetic results.