Aluminum curtain wall profiles are structural components used in modern architecture for their lightweight, high strength, and corrosion resistance. They enhance building aesthetics while providing structural support and protection.

Specifications of curtain wall aluminum profiles

| Alloy | 6000 series, commonly used 6063, 6061 |

| Length | 6m or customized according to drawings |

| Color | Black, silver, bronze, champagne, black or customized |

| Shape | Square, round, flat, oval, and customized according to customer drawings |

| Surface | Anodizing, powder coating, electrophoresis, wood grain, polishing, etc. |

| Package | Pearl cotton, outer shrink film or customized. |

Common types of curtain wall aluminum profile

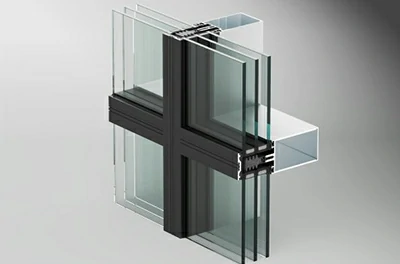

Aluminum profiles for clear-frame glass curtain walls

Aluminum profiles for clear-frame glass curtain walls- The outer frame and transoms are clearly visible on the building facade, accentuating the architectural lines and structural beauty.

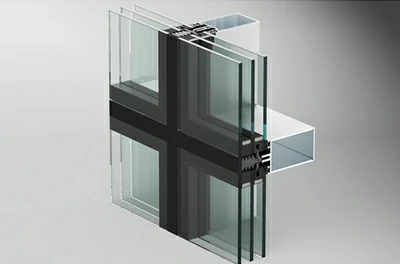

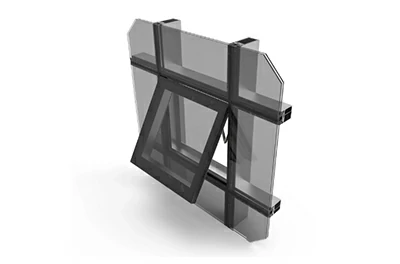

Aluminum profiles for semi-concealed-frame glass curtain walls

Aluminum profiles for semi-concealed-frame glass curtain walls- Some frames are hidden while others are exposed, combining the features of both clear-frame and concealed-frame curtain walls.

Aluminum profiles for concealed-frame glass curtain walls

Aluminum profiles for concealed-frame glass curtain walls- The frames are hidden behind the panels, resulting in a smooth and sleek appearance.

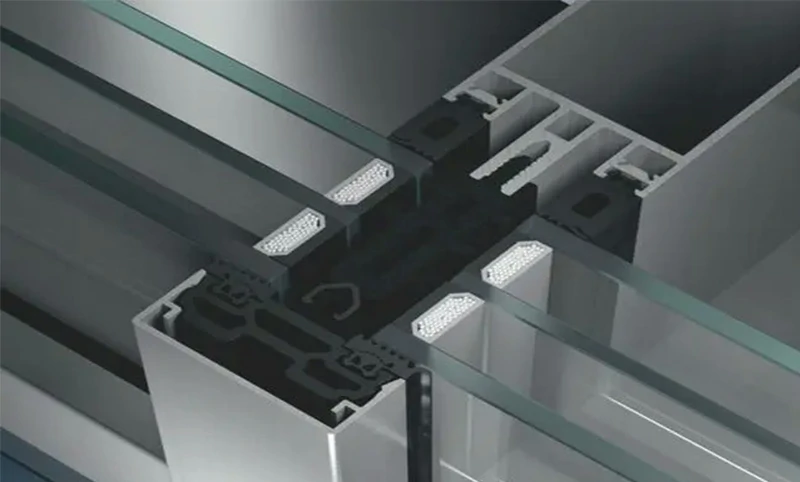

Aluminum profiles for curtain wall corner connectors

Aluminum profiles for curtain wall corner connectors- They are used to connect and secure columns, beams, and other frame components, ensuring the stability and safety of the structure.

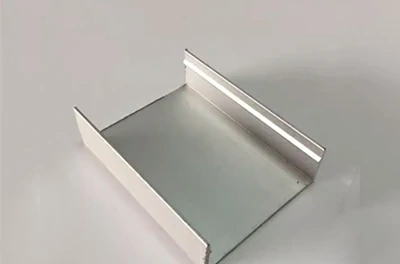

Aluminum alloy curtain wall pressure plates

Aluminum alloy curtain wall pressure plates- They are crucial components in curtain wall systems, used to secure glass or panel materials, ensuring structural stability.

Curtain wall pressure plate cover profiles

Curtain wall pressure plate cover profiles- They are used to cover and protect the pressure plates, enhancing aesthetics and protective performance.

Curtain wall glass mullion profiles

Curtain wall glass mullion profiles- They are the skeleton of curtain wall systems, used to support and secure glass or other metal panel materials, ensuring the stability and safety of the entire curtain wall structure.

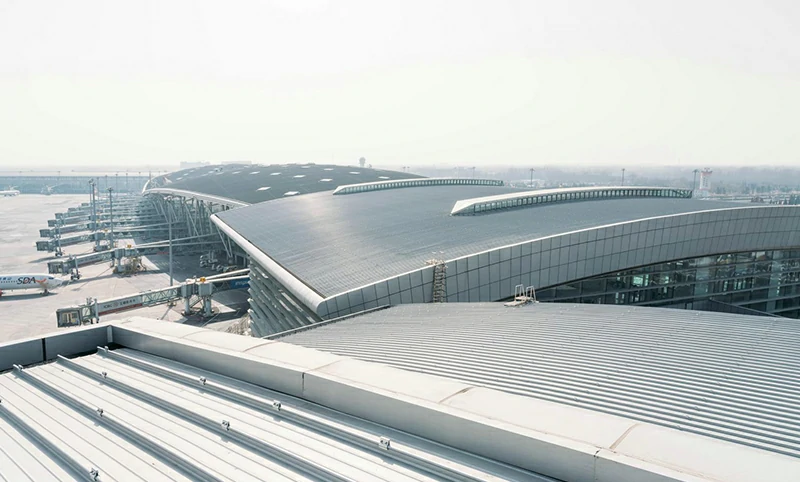

Application of curtain wall aluminum profiles

Aluminum curtain wall profiles are widely used in modern office buildings, not only enhancing the building's modern and stylish appearance but also providing excellent thermal insulation, insulation, and soundproofing effects, creating a comfortable office environment.

Large shopping centers utilize aluminum curtain wall profiles to achieve extensive glass curtain wall designs, enhancing daylighting effects and visual transparency, attracting more customers.

Airports require extensive transparent curtain walls to increase light transmission rates and create a spacious atmosphere.

Large public buildings such as exhibition halls and conference centers benefit from the flexibility and aesthetics of aluminum curtain wall profiles, making them an ideal choice.

High-rise residential buildings and luxury apartments adopt aluminum curtain wall profiles, offering not only a stylish appearance but also improving the durability and safety of the structure.

Advantages of MASTAR curtain wall aluminum profiles

As a professional supplier of aluminum curtain wall profiles, MASTAR offers high-quality curtain wall profiles with the following advantages:

- Lightweight: Curtain wall aluminum profiles are favored for their excellent strength-to-weight ratio. Aluminum is inherently lightweight, making it an ideal material for constructing large curtain walls without imposing excessive loads on the building structure.

- Corrosion resistance: Aluminum is naturally corrosion-resistant, and its corrosion resistance can be further enhanced through processes such as anodizing, electrophoretic coating, and powder coating.

- Flexibility in design: Aluminum alloy profiles can be processed into various complex cross-sectional shapes through extrusion processes to meet the diverse design requirements of different buildings.

- Aesthetics: Surface treatments such as anodizing and powder coating provide a variety of color and texture options, meeting the aesthetic needs of building exteriors.

- Fire resistance: Aluminum alloys are non-combustible materials and do not release harmful gases during fires, thereby increasing the safety of buildings.

- Ease of processing: Aluminum is easy to process and can be adapted to more curved building profiles through secondary processes such as bending, meeting the design requirements of curved architectural curtain walls.

Considerations for selecting curtain wall aluminum profiles

Material Strength: Aluminum profiles for curtain walls must meet specific strength requirements to withstand environmental factors like wind loads and seismic forces. Material strength directly impacts the overall stability and lifespan of the curtain wall system.

Thermal Performance: Aluminum profiles often include thermal insulation technology to improve energy efficiency. This involves using materials with low thermal conductivity to reduce heat transfer, enhancing insulation and energy savings.

Customization and Surface Treatment: Customizable aluminum profiles in size, shape, and surface treatment allow architects to achieve their desired aesthetic. Anodizing or powder coating finishes enhance appearance and provide corrosion protection.

Installation and Assembly: Prefabricated systems enable easy on-site assembly, contributing to cost-effectiveness and simplifying the construction process.

Why choose Mastar-Metal as your aluminum supplier

- MASTAR uses high-quality aluminum alloy, and the quality and performance of aluminum profiles are guaranteed.

- Rich inventory, a wide variety of sizes, support cutting, and fast delivery.

- With a large number of profile molds, you can save mold opening costs.

- For bulk purchase customers, the price will be more competitive.

- Provide various quality inspection reports, product quality assurance, buy with confidence.

- Rich colors to meet any decoration needs.