We have complete system certifications and adhere to strict technical standards, committed to reducing carbon footprints during the manufacturing stage. By customizing the alloy, section, thickness, and dimensions of aluminum bumper beams, we meet the needs of different vehicle models.

Additionally, we focus on custom R&D for automotive components, aiming to provide efficient and eco-friendly solutions to ensure timely and rapid delivery of your projects.

Aluminum bumper beam specifications

Standards: ASTM B221, EN 755, ISO 6361, FMVSS 581, FMVSS 215, ECE R42

Certifications: IATF 16949, TÜV Certified

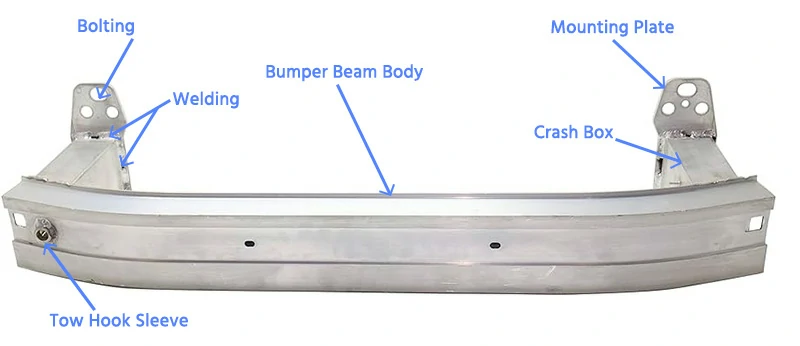

Mastar offers a complete range of automotive bumper beam products

- Bumper Beam

- Crush Can

- Mounting Plate

- Tow Hook Cover

Automotive bumper solutions: supplying 6-series and 7-series aluminum alloy and composite beams

6-Series Aluminum Bumper Beams

6-Series Aluminum Bumper Beams- Common 6-series alloys include 6082-T6, 6060-T6, 6063-T6, and 6061-T6. These alloys offer excellent tensile and yield strength while maintaining good ductility.

- They are also suitable for various processes such as anodizing, bending, forming, stamping, welding, and machining, making them highly cost-effective for mass production.

7-Series Aluminum Bumper Beams

7-Series Aluminum Bumper Beams- 7-series aluminum alloys are widely used in high-end vehicles due to their exceptional hardness and strength. Common grades include 7003-T6 and 7049-T73.

Steel-Aluminum Composite Bumper Beams

Steel-Aluminum Composite Bumper Beams- Steel-aluminum composite bumper beams combine the high strength of steel with the lightweight properties of aluminum, typically used in hybrid and electric vehicles.

Aluminum-Carbon Fiber Composite Bumper Beams

Aluminum-Carbon Fiber Composite Bumper Beams- Aluminum-carbon fiber composite bumper beams enhance vehicle acceleration and handling by reducing weight, making them primarily used in high-performance sports cars.

Aluminum bumper beam sections we supply: diverse options, outstanding performance

We offer a range of aluminum bumper beam sections to meet various vehicle and design requirements. These products are popular in the market and have passed rigorous crash tests.

Popular aluminum bumper beam section types

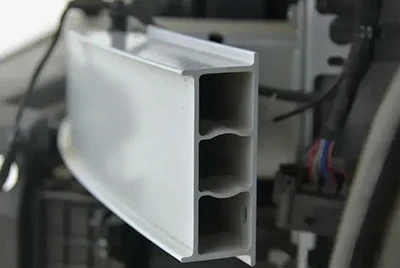

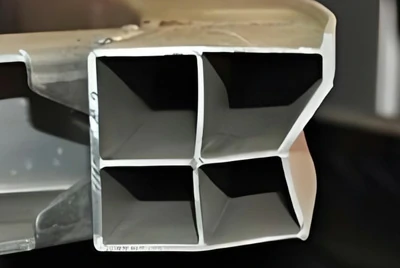

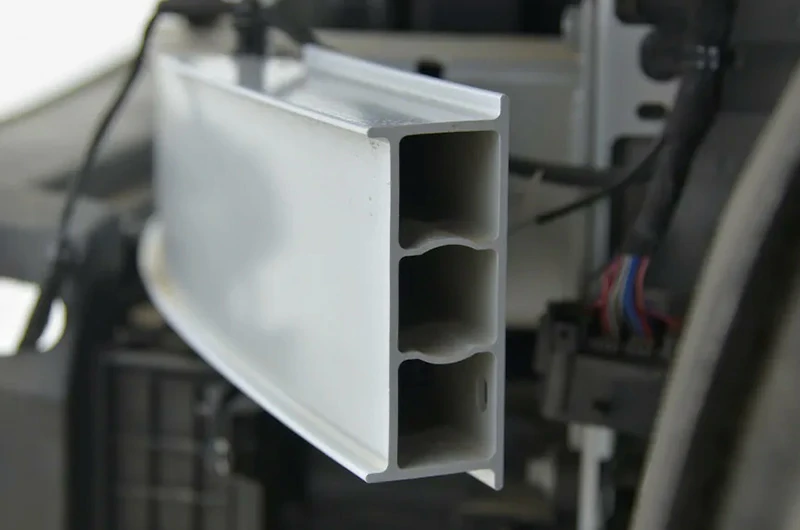

- This type of section is typically manufactured using extrusion processes. By controlling the thickness and width of the aluminum, its strength and energy absorption capabilities can be adjusted.

- This symmetric and simple design is widely used in most automotive bumper beams.

- This section features internal partitions that enhance the rigidity and strength of the beam.

- It offers better energy absorption during collision impacts and is suitable for vehicle designs requiring higher impact strength.

- This section is a closed rectangular structure that offers excellent torsional rigidity and strength, effectively absorbing and dissipating energy during collisions.

- It is cost-effective to extrude and is commonly found in lower-end vehicle models.

- This section includes multiple intersecting reinforcements internally.

- The design of these reinforcements further enhances the beam's bending strength and compression resistance, making it exceptionally effective against high-impact collisions, suitable for high-end vehicle designs.

- Roll-formed bumper beams have high material utilization and low cost, making them suitable for mass production.

Other recommended aluminum bumper beam section types

Stamped sections feature simple design and low cost, making them suitable for rapid mass production. They are commonly used for rear bumper beams.

Chemical elements of aluminum alloy bumper beams (Spec: BS EN 573-3:2009)

As a specialized aluminum supplier with extensive technical expertise and experience, we can finely adjust the chemical composition of extruded aluminum billets based on your specific requirements.

By optimizing the ratios of elements such as Mg, Si, Zn, Cu, and Mn, we can tailor high-performance aluminum alloys to meet stringent demands for strength, elongation, and extrudability.

| Element | 6082-T6 | 6060-T6 | 6063-T6 | 6061-T6 |

| Silicon (Si) | 0.70 - 1.30% | 0.30 - 0.60% | 0.20 - 0.60% | 0.40 - 0.80% |

| Iron (Fe) | ≤ 0.50% | 0.10 - 0.30% | ≤ 0.35% | ≤ 0.70% |

| Copper (Cu) | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | 0.15 - 0.40% |

| Manganese (Mn) | 0.40 - 1.00% | ≤ 0.10% | ≤ 0.10% | ≤ 0.15% |

| Magnesium (Mg) | 0.60 - 1.20% | 0.35 - 0.60% | 0.45 - 0.90% | 0.80 - 1.20% |

| Chromium (Cr) | ≤ 0.25% | ≤ 0.05% | ≤ 0.10% | 0.04 - 0.35% |

| Zinc (Zn) | ≤ 0.20% | ≤ 0.15% | ≤ 0.10% | ≤ 0.25% |

| Titanium (Ti) | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | ≤ 0.15% |

| Other elements (Each) | ≤ 0.05% | ≤ 0.05% | ≤ 0.05% | ≤ 0.05% |

| Other elements (Total) | ≤ 0.15% | ≤ 0.15% | ≤ 0.15% | ≤ 0.15% |

| Aluminum (Al) | Remainder | Remainder | Remainder | Remainder |

Mechanical properties of aluminum alloy bumper beams (Spec: BS EN 755-2:2008)

The performance of aluminum alloy bumper beams is crucial in real-world collisions. Please provide your specific performance requirements, and we can offer customized solutions to meet your needs.Quick Quote

| Property | 6082-T6 | 6060-T6 | 6063-T6 | 6061-T6 |

| Tensile Strength (Rm) | ≥ 310 MPa | ≥ 190 MPa | ≥ 215 MPa | ≥ 290 MPa |

| Yield Strength (Rp0.2) | ≥ 260 MPa | ≥ 150 MPa | ≥ 170 MPa | ≥ 240 MPa |

| Elongation (A50) | ≥ 8% | ≥ 8% | ≥ 8% | ≥ 8% |

| Brinell Hardness (HB) | 95 - 100 | 60 - 75 | 60 - 75 | 95 - 100 |

Classic cases of aluminum alloy bumper beams

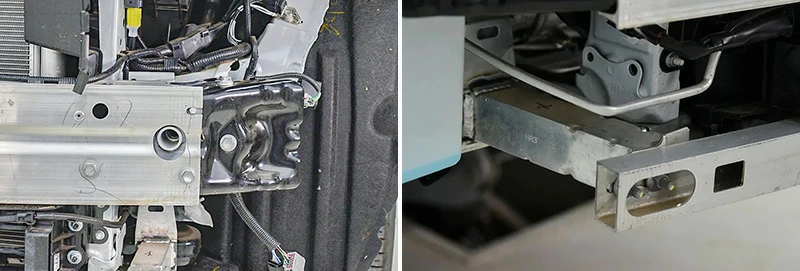

Aluminum bumper beams and crush cans are popular in both ICE and EV models. Many automotive companies, including Honda, Toyota, Tesla, Kia, Hyundai, Chevrolet, and Mercedes-Benz, use extruded aluminum alloy bumper beams.

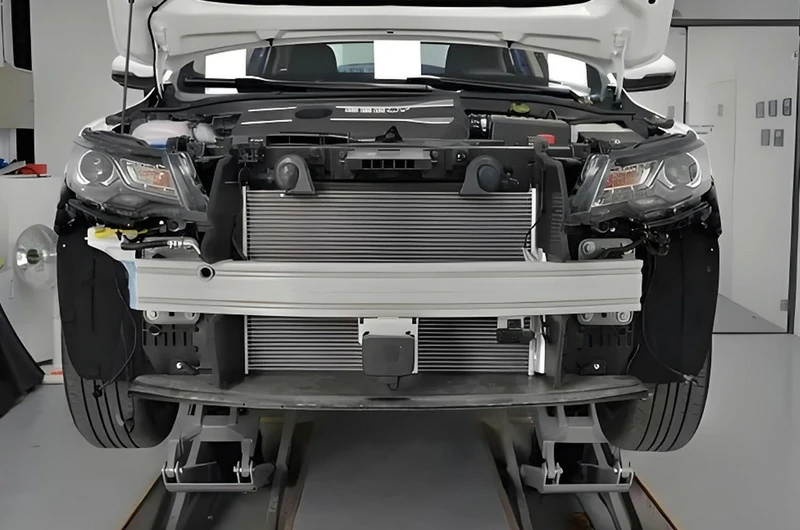

2020 Toyota RAV4 front bumper beam

The sales of the American SUV king show no signs of slowing down, and it has become one of the top three best-selling models in the U.S. The RAV4 front crash beam is made from extruded aluminum alloy, featuring a "C" shaped cross-section, with a thickness of 2.27mm and a length of approximately 1490mm, covering 80.28% of the front of the vehicle.

Notably, the crush can also includes collapse folds. Additionally, it is equipped with an aluminum alloy secondary bumper beam to prevent pedestrian entrapment.

2021 Chevrolet Equinox front bumper beam

The Chevrolet Equinox features a very thick aluminum alloy crash beam, with a thickness of 5.1mm and a length of approximately 1334mm, covering 72.32% of the front of the vehicle.

2021 Tesla Model Y front bumper beam

The 2021 Tesla Model Y features an aluminum front crash beam with a thickness of 4.41mm and a length of approximately 1524mm, covering about 79.37% of the front of the vehicle. Compared to the 3.01mm thick crash beam on the Model 3, the Model Y's beam is thicker.

Like the Model 3, the Model Y also includes a wide-coverage extruded secondary crash beam.

2024 BYD Song L EV front bumper beam

The 2024 BYD Song L EV features an aluminum front crash beam with a thickness of 2.98mm and a length of approximately 1552mm, covering about 79.57% of the front of the vehicle.

The aluminum front crash beam has two curved reinforcing ribs in its cross-section, which enhance energy absorption during actual collisions.

2022 Mercedes-Benz C-Class front bumper beam

The 2022 Mercedes-Benz C-Class features an aluminum front crash beam with a thickness of 4.51mm and a length of approximately 1614mm, covering about 88.70% of the front of the vehicle.

Compared to the previous generation C-Class, the new model includes an additional aluminum secondary crash beam designed to prevent pedestrian entrapment.

As an experienced supplier, we are always ready to provide you with high-quality service. If you have any needs, please feel free to contact us at any time.Quick Quote

Rigorous testing ensures safety

Our company applies almost stringent quality standards to the production of bumper beams. Through a series of rigorous tests, we ensure that each product meets or even exceeds industry standards.

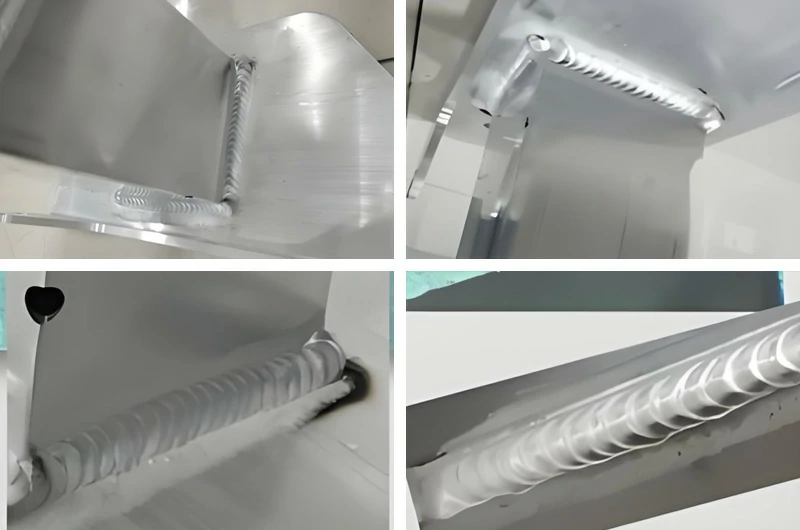

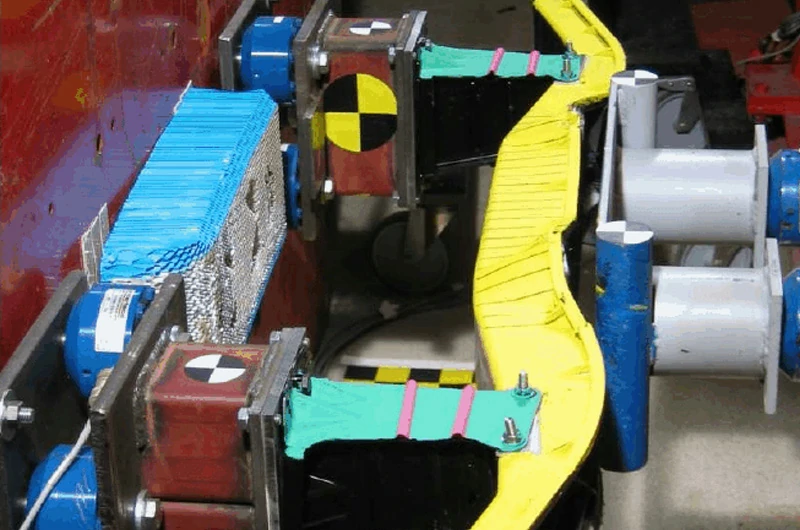

Crush can compression test: simulating real collision scenarios

We place the sample on a universal testing machine and compress it at a rate of 100mm/min until the compression reaches 70%.

As shown in the image below, the Crush Can sample did not crack during the test, meeting the customer's requirements.

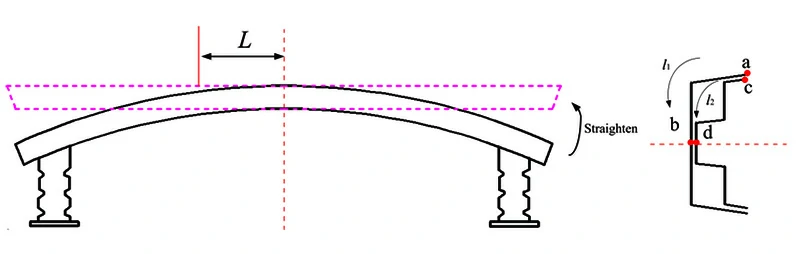

Bumper beam under three-point bending

In addition to the compression test, we also conducted a three-point static bending test to simulate the stress conditions during low-speed collisions.

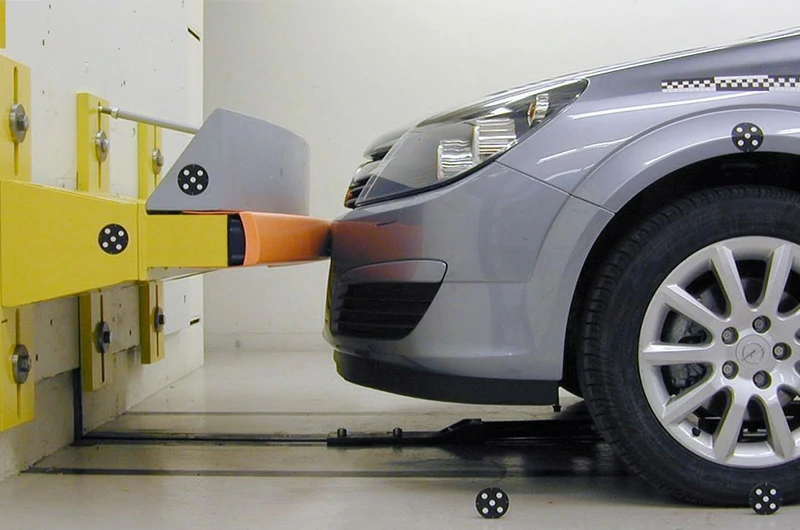

Fixture impact test

To more comprehensively assess the performance of the bumper beam, we also conducted a fixture impact test.

Pendulum impact test: conforming to international standards

In accordance with relevant standards from the United States and Canada, we use a pendulum to conduct impact tests on the bumper beam, assessing its energy absorption capacity at various impact speeds and angles.

Precise craftsmanship and advanced technology: enhancing the superior quality of bumper beams

Mastar's bumper beams are manufactured using processes such as extrusion, high-speed sawing, passivation, bending, milling, machining, welding, and heat treatment. The final assembly is done through welding or bolting.

The products can be subjected to surface treatments like anodizing or painting to meet appearance requirements, achieving the desired flatness and corrosion resistance.

Optimization of the extrusion process for bumper beams

- Lower Extrusion Temperature: Reduce thermal stress on the alloy and improve material flow, which helps increase the extrusion speed.

- Increase Extrusion Speed: Raise the extrusion speed slightly while ensuring product quality to shorten the production cycle.

- Optimize Quenching Method: Use a combination of air cooling and water spraying for quenching to rapidly cool the alloy and maintain its microstructure and mechanical properties.

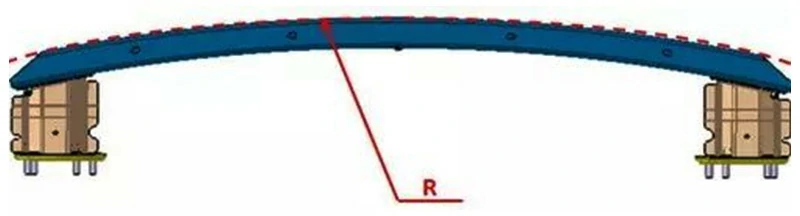

Bending techniques for bumper beams

Curved Bending: The curvature should be minimal; excessive curvature might cause the front beam to push the energy absorber sideways during a collision, leading to bending of the absorber and reducing its energy absorption effectiveness. The radius of the front end arc of the collision beam typically ranges between R2000mm and R4000mm.

Straight Bending: It is not a straight bend throughout but rather includes slight corner bends at both ends of the energy absorber. The diagonal lines of the corners are approximately tangent to the outer surface.

Bumper beam welding case

We use advanced bumper welding stations, significantly enhancing welding precision and quality, ensuring outstanding welding performance.