Aluminum finned tubes are durable, efficient, and cost-effective heat exchange elements. They offer high heat transfer efficiency, large heat dissipation area, long service life, wide operating temperature range, and the ability to withstand high pressure.

Mastar provides high-quality and competitively priced aluminum finned tubes with lateral, longitudinal, and serrated fins, as well as composite extruded finned tubes, ensuring reliable quality and excellent performance.

Specifications of aluminum finned tubes

Standards: ASTM B221, ASTM B429, EN 755, EN 573, NACE MR0175

Certifications: ROHS, ISO, CE, UL

Popular aluminum finned tube products

We offer finned tubes in various materials and sizes based on customer requirements. The tubes can also be bent into the shapes needed for your application.

Choose our aluminum finned tubes to ensure more stable operation and lower costs for your equipment.Quick Quote

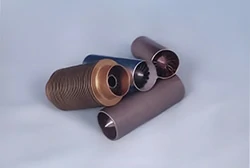

Extruded finned tubes

Extruded aluminum finned tubes are popular for their durability, high heat transfer efficiency, lightweight structure, and corrosion resistance. They are widely used in air-cooled heat exchangers, condensers, and evaporators across various industries.

Aluminum Alloys: 1050, 1060, 6063

Tube Diameter: 1" to 1-1/2"

Fin Height: 1/2" to 5/8"

Fin Spacing: 8 fins/inch to 13 fins/inch

Low fin tube

Aluminum Alloys: 1050, 1060, 1100

Low fin tubes, also known as Trufin tubes, are finned tubes produced through plastic cold deformation. This process enhances heat exchange efficiency and can reduce the size of heat exchangers. They are commonly used in heat exchangers for power generation, chemical processing, and refineries.

Longitudinal finned tube

Longitudinal finned tubes can be positioned vertically or horizontally within equipment to provide optimal heat transfer and efficiency. They are commonly used in heat transfer applications for power generation, energy recovery, petrochemical, oil, and gas industries.

Alloys: 1060, 1100, 5052

Tube Length: Up to 100 feet

Tube Diameter: From ¾" to 16"

Fin Height: 7/32" to 1-1/2"

Fin Thickness: .035" to .050"

Embedded fin tube

The secure bond between the fins and the tube in embedded fin tubes makes them highly suitable for applications exposed to high temperatures, continuous thermal cycling, and tube vibrations caused by high-speed airflow. This tube is suitable for applications with temperatures up to 750°F.

Alloys: 1050, 1060, 5052, 6063

Tube Diameter: 9/16" to 2"

Fin Height: 1/4" to 5/8"

Fin Spacing: 5 fins/inch to 13 fins/inch

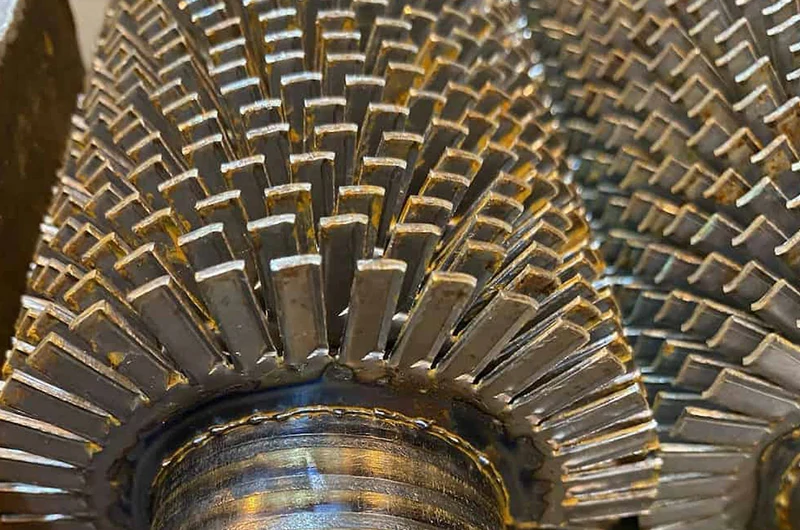

Spiral serrated fin tube

Spiral serrated fin tubes are used in applications related to boilers, gas turbines in power generation, and furnaces in petrochemical processing and refining.

Alloy: 6063

Tube Diameter: 1" to 8.625"

Fin Height: 3/8" to 1-1/2"

Fin Thickness: .035" to .075"

Fin Spacing: 3/4 fins/inch to 7 fins/inch

Fin tube coil

Alloys: 1050, 1060, 1100

Laser-welded fin tube coils feature a compact design and high thermal efficiency. We can supply fin tubes in various sizes, from micro-fin tubes to large diameter spiral coils, including bare tubes, conical coils, and double-wound coils, based on customer specifications.

We have the capability to handle any bending projects. Fin tubes can be twisted and bent into various shapes.

Mastar's other aluminum finned tube products

- Crimped Fin Tube

- G Type Finned Tube

- H Type Finned Tubes

- L Type Fin Tube

- High Fin Tube

- Internally Finned Tubes

Why use aluminum finned tubes

- Corrosion Resistance: Aluminum offers strong corrosion resistance, making it suitable for harsh environments.

- Lightweight: Aluminum finned tubes are easy to transport and install, particularly beneficial for aerospace and automotive industries.

- Low Maintenance Cost: These tubes require minimal maintenance, extending the lifespan of equipment.

- High Thermal Efficiency: Aluminum finned tubes have a heat dissipation area that is 7-8 times greater than bare tubes, resulting in high heat exchange efficiency.

- Versatility: They are suitable for air-to-air, air-to-liquid, liquid-to-liquid, and various fluid heat exchanges, meeting diverse industry needs.

- High-Temperature Strength and Thermal Expansion Performance: Aluminum finned tubes maintain stable performance in high-temperature environments, reducing high-temperature corrosion and overheating damage to metal surfaces.

- Good Welding Performance: Aluminum finned tubes have a low thermal expansion coefficient, facilitating processing and forming.

We can save more costs!

By increasing the external surface area of finned tubes, the overall heat transfer rate is enhanced, reducing the total number of aluminum tubes needed for a given application.

This can lower the overall size of the equipment and project costs. In many cases, one finned tube can replace six or more bare tubes, costing less than one-third of the original amount and reducing the volume by one-fourth.Quick Quote

Service when you need it most

- We offer samples based on your needs, with bulk production customized only after your satisfaction.

- We provide professional and fast quotations with timely delivery. We offer a wide range of finned tube products and extensive service coverage.

- To meet the demand for extra-long finned tubes, we provide finned tube butt welding services.

- Finned tubes can be tailored to your specific requirements to ensure a perfect fit.

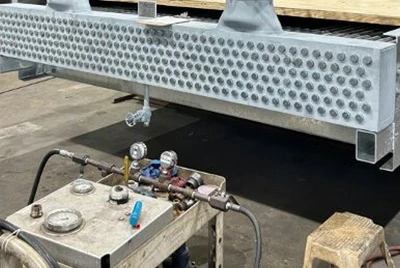

Reliable quality

- Our products meet industry and safety standards, ensuring you can trust in their quality.

- All our finned tubes are manufactured to ensure dimensional accuracy and welding quality meet specifications.

- Our coatings provide robust corrosion protection.

- Finished products are tested according to customer requirements, typically including PMI, X-ray, dye penetrant inspection, or hydrostatic pressure testing.

How to determine the optimal finned tube density for heat exchangers

The fin density of aluminum finned tubes significantly impacts heat transfer performance. Higher fin density increases the surface area, enhancing heat transfer efficiency, but it may also result in higher pressure drops and airflow resistance.

How to order finned tubes

To provide you with a quick quote and the most comprehensive solution, we need the following information to determine the suitable finned tube for your needs:

1.What fluid will pass through the finned tube (e.g., air, water, glycol, heat-sensitive liquids)?

2.What are the maximum pressure and temperature inside the tube?

3.What is flowing around the finned tube (e.g., ambient air, fan cooling, exhaust gases)?

4.What is the maximum external temperature of the finned tube?

5.What diameter and thickness are required?

6.What base tube material is needed (e.g., 316 stainless steel, 304 stainless steel, aluminum, carbon steel, copper)?

7.What fin height, density, and thickness are required?

To order finned tubes, please call +60 189075899 or email sale@mastar-metal.com.Quick Quote