2024 aluminum tubes typically feature high strength, excellent machinability, lightweight properties, efficient heat conduction in t3 and t4 temper, ease of bending and forming, and outstanding welding capabilities.

2024 Aluminum Tube is commonly used in aerospace, automotive, machinery, and industrial applications.

MASTAR 2024 aluminum tube product specifications

Equivalent name: 2024, EN AW-2024, AW-AlCu4Mg1, AU4G1, 3.1355, A92024, AlCu4Mg1, AlCuMg2

Length: Max 30M Fix & Cut Length or Customized

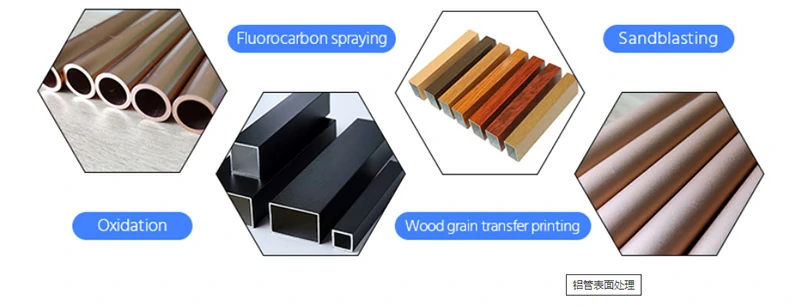

Color: Silver, gold, natural, silver, champagne, red, grey, black, custom

Types of sluminum tubes: precision aluminum tube, seamless aluminum tube, thin-walled aluminum tube, extruded tube, cold-drawn aluminum tube, forged tube

Surface treatment: anodizing, powder coating, polishing, coating

Processing services: CNC cutting, drilling, etching, bending

MASTAR 2024 aluminum tube best-selling products and mechanical properties

| Description | Tensile Strength | Shear Strength | Fatigue Strength | Elastic Modulus | Brinell Hardness | Elongation at Break |

| 2024 T3 aluminum tube High strength and good fatigue performance | 320-480 MPa | 290 MPa | 140 MPa | 71 GPa | 120 | 15% |

| 2024 T351 aluminum tube No residual stress | 330-460 MPa | 290 MPa | 140 MPa | 71 GPa | 120 | 13% |

| 2024 T4 aluminum tube Good toughness, strength slightly lower than T3 | 310-480 MPa | 290 MPa | 140 MPa | 71 GPa | 120 | 16% |

| 2024 O aluminum tube Best ductility and formability | 100-200 MPa | 130 MPa | 90 MPa | 71 GPa | 49 | 15% |

MASTAR 2024 aluminum tube hot selling products

2024 cold drawn aluminum round tube

2024 cold drawn aluminum round tube- OD:0.2"-8.66"(5-220mm)

- WA: 0.02"-0.39"(0.5-10mm)

- Standard:ASTM-B210, AMS-4088, AMS-WW-T-700/3

- Cold drawing significantly increases the strength and hardness of 2024 aluminum tubes through plastic deformation.

2024 seamless aluminum round tube

2024 seamless aluminum round tube- OD: 3.543"-11.81"(90-300mm)

- WA: 0.2"-0.79"(5-20mm)

- Standard: AMS 4088, WW-T-700/3

- The compression resistance of seamless aluminum tubes is better than that of seamed aluminum tubes, and the texture is uniform. If it is a bent tube, it is recommended to use seamless aluminum tubes.

2024 seamless aluminum hexagonal tube

2024 seamless aluminum hexagonal tube- AF: 0.197"-1.181"(5-30mm)

- WA: 0.039"-0.591(1-15mm)

- Standard: ASTM B241/B241M,EN 754-2

- The hexagonal shape provides increased bending stiffness and torsional performance.

2024 extruded aluminum rectangular tube

2024 extruded aluminum rectangular tube- Width: 0.197"-11.811(5-300mm)

- Height: 0.394"-11.811"(10-300mm)

- Standard: AMS 4153, QQ-A-200/2

- Extrusion ensures the uniformity of properties across the entire cross-section of the aluminum tube, reducing internal defects and inconsistencies.

2024 Precision aluminum round tube

2024 Precision aluminum round tube- OD: 0.236"-7.874"(6-200mm)

- WA: 0.0197"-0.787"(0.5-20mm)

- Standard: ASTM B210, AMS 4086

- 2024 precision aluminum round tube has high dimensional accuracy and good machinability

2024 precision aluminum square tube

2024 precision aluminum square tube- Side length: 0.394"-7.874"(10-200mm)

- WA: 0.039"-0.394"(1-10mm)

- Standard: AMS 4152

- 2024 precision aluminum square tubes have higher stiffness and strength when resisting bending and torsion, making them less prone to deformation.

2024 forged aluminum oval tube

2024 forged aluminum oval tube- Minor axis: 0.394"-7.874"(10-200mm)

- Major axis: 0.787"-15.748"(20-400mm)

- WA: 0.039"-0.787" (1-20mm)

- Standard: AMS 4140,EN 586-2

- Aluminum oval tube provides excellent aerodynamic design and performance advantages

Characteristics and advantages of 2024 aluminum tubes

High strength and lightweight: 2024 aluminum alloy is known for its high strength, particularly in the T3 and T351 heat-treated states. It combines strength with lightweight properties.

Ease of bending and forming: 2024 aluminum tubes exhibit excellent ductility, allowing for complex shapes to be formed through both cold and hot working processes. It offers higher plasticity and toughness compared to 7075 aluminum alloy.

High thermal conductivity: 2024 aluminum alloy demonstrates outstanding thermal conductivity. By utilizing appropriate heat treatment processes such as T3 and T4 states, both mechanical and thermal properties of the material can be further enhanced.

Corrosion resistance: While the corrosion resistance of 2024 aluminum alloy is not as high as some other aluminum alloys like 6061, it can be significantly improved through surface treatment processes such as anodizing, thereby extending its lifespan.

Cooperation industrial field of MASTAR 2024 aluminum tube products

- Aerospace Industry: 2024 aluminum tubes are widely used in aircraft structures and components such as fuselages, wings, and supports.

- Transportation and Automotive: Applied in the manufacture of light trucks, off-road vehicles, and high-performance racing cars.

- Marine Engineering: Utilized in the manufacture of ships, marine equipment, and offshore platforms.

- Industrial Equipment: Used for manufacturing industrial equipment and mechanical components requiring high strength and corrosion resistance.

- Sports Equipment: Applied in the manufacturing of high-performance sports equipment such as golf clubs, arrow shafts, and tennis rackets.

- Construction and Building Materials: Used in construction for structural supports, frameworks, and decorative components.

Reasons to choose MASTAR 2024 aluminum tube

- MASTAR stocks 2024 aluminum tubes in a variety of tempers, shapes and specifications.

- MASTAR specializes in offering customized tube profiles, encompassing various special shapes.

- MASTAR offer a range of processing options, including extruded, drawn, and hydraulic tubes which can custom cut lengths to cater to diverse requirements.

- Relying on MASTAR production line and its subsidiaries, source procurement, lowest price guarantee.

- MASTAR 2024 aluminum tubes adhere to EN 754,AMS 4088 , ASTM B210 standard certifications, with a guaranteed seven-day delivery.