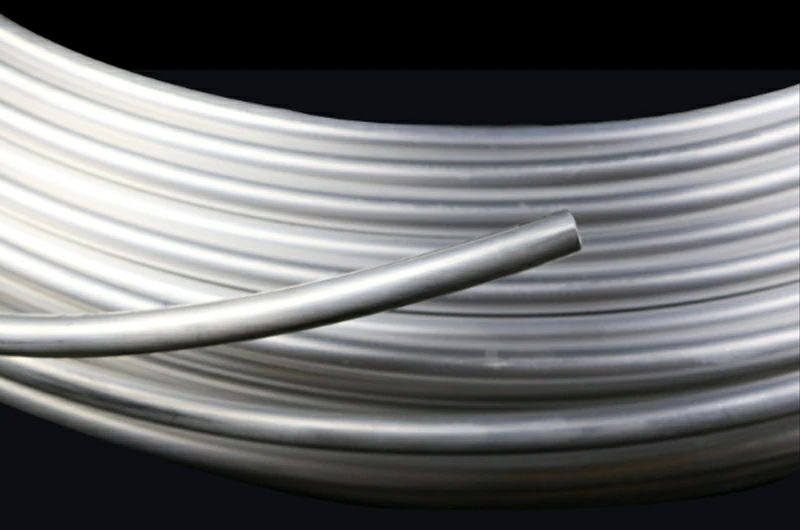

MASTAR offers heat treatable, non-heat treatable, diamond treaded and coated, pre-painted aluminum coil tubing in a variety of alloys. Typically used in applications requiring good thermal and electrical conductivity as well as good formability and welding capabilities. As HVAC parts come with a 5-year quality promise.

Specification of aluminum coil tube

Hot selling alloys: 3003 3103 1050 1060 1070 1100 1200 5052 5083 2024, etc.

Temper: O H112 H14 H18 H24 H28 etc.

Coil: ID 400mm-500mm, OD 750mm-1200mm, Height 310mm/400mm

Tube cross section shape: round, flat, oval...

Surface treatment: grinding, anodizing, powder coating, polishing, sandblasting

Tube surface pattern: diamond pattern, rhombus pattern, orange peel pattern, five-ribbed pattern, etc.

End closure methods: deburred, Open/rounded, Sharp/flattened, Welded shut, Pierced, Swage & tapered, Beveled, Threaded, etc.

MASTAR aluminum coil tube hot selling size reference table

| MASTAR aluminum coil tube inch size reference table | ||||

| describe | Pipe diameter inch | Wall thickness inches | Lengthft | |

| .125″OD X .025″WX 50'L ALUM (1/8″) | 0.125 | 1/8 | 0.025 | 15,25,30,50 |

| .1875″OD X.028″W X 50'L ALUM (3/16″) | 0.1875 | 3/16 | 0.028 | 15,25,30,50 |

| .250″OD X .032″W X 50'L ALUM (1/4″) | 0.250 | 1/4 | 0.032 | 15,25,30,50 |

| .250″OD X .049″W X 50'L ALUM (1/4″) | 0.250 | 1/4 | 0.049 | 15,25,30,50 |

| .3125″OD X .035″W X 50'L ALUM (5/16″) | 0.3125 | 5/16 | 0.035 | 15,25,30,50 |

| .375″OD X .035″W X 50'L ALUM (3/8″) | 0.375 | 3/8 | 0.035 | 15,25,30,50 |

| .375″OD X .049″W X 50'L ALUM (3/8″) | 0.375 | 3/8 | 0.049 | 15,25,30,50 |

| .4375″OD X .035″W X 50′ ALUM (7/16″) | 0.4375 | 7/16 | 0.035 | 15,25,30,50 |

| .500″OD X .035″W X 50'L ALUM (1/2″) | 0.500 | 1/2 | 0.035 | 15,25,30,50 |

| .500″OD X .049″W X 50'L ALUM (1/2″) | 0.500 | 1/2 | 0.049 | 15,25,30,50 |

| .500″OD X .065″W X 50'L ALUM (1/2″) | 0.500 | 1/2 | 0.065 | 15,25,30,50 |

| .625″OD X .035″W X 50'L ALUM (5/8″) | 0.625 | 5/8 | 0.035 | 15,25,30,50 |

| .625″OD X .049″W X 50'L ALUM (5/8″) | 0.625 | 5/8 | 0.049 | 15,25,30,50 |

| MASTAR aluminum coil tube metric size reference table | ||

| Outer Diameter * Inner Hole * Wall Thickness (mm) (Customization Can Be Supported) | ||

| OD 4.0*ID 2.0*THICK 1.0MM | OD 9.52*ID 8.12*THICK 0.7MM | OD 12.7*ID 10.7*THICK 1.0MM |

| OD 5.0*ID 3.0*THICK 1.0MM | OD 9.52*ID 7.52*THICK 1.0MM | OD 15*ID 13*THICK 1.0MM |

| OD 6.0*ID 4.7*THICK 0.65MM | OD 10.0*ID 8*THICK 1.0MM | OD 15.88*ID 14.08*THICK 0.9MM |

| OD 6.0*ID 4.0*THICK 1.0MM | OD 12.0*ID 10.4*THICK 0.8MM | OD 15.88*ID 13.48*THICK 1.2MM |

| OD 8.0*ID 6.6*THICK 0.7MM | OD 12.0*ID 10*THICK 1.0MM | OD 16.0*ID 14*THICK 1.0MM |

| OD 8.0*ID 6.0*THICK 1.0MM | OD 12.7*ID 11.1*THICK 0.8MM | OD 19.05*ID 16.65*THICK 1.2MM |

MASTAR aluminum coil tube hot selling alloy products

- 3003 O H14 aluminum coil tube

Good corrosion resistance, plasticity and processing properties, as well as excellent thermal conductivity and welding properties, suitable for ventilation systems, air-conditioning systems, etc.

- 3105 H14 H22 H24 aluminum alloy coil

Good corrosion resistance and weldability, suitable for applications requiring weather resistance.

- 1050 1060 1070 O H12 H14 H112 aluminum alloy coil

Pure aluminum has good processability, formability and conductivity.

- 1100 1200 O H14 H112 aluminum alloy coil

Pure aluminum has excellent thermal conductivity, good processability and corrosion resistance, and is mainly used in automobile cooling systems, etc.

- 5052 5083 5086 O H32 H34 aluminum alloy coil

Higher strength and excellent corrosion resistance, suitable for applications requiring higher strength and corrosion resistance.

- 6061 6063 6082 T5 T6 T6511 aluminum alloy coil

Good mechanical properties, heat treatment properties and strength, suitable for applications with high strength requirements.

- 2024 T3 aluminum alloy coil

High strength and good corrosion resistance, suitable for areas with high requirements on strength and rigidity.

MASTAR aluminum coil tube technical parameters and quality inspection

| Alloy | Temper | Room temperature Test Result | ||

| Tensi le Strength/MPa | Yield Strength/MPa | Elongation/% | ||

| Not less than | ||||

| 3003 | O | 110 | 40 | 28 |

| H14 | 160 | 130 | 8.3 | |

| 3105 | H22 | 120 | 150 | 7.4 |

| H24 | 140 | 170 | 5.6 | |

| 1050 | O, H111 | 76 | 25 | 37 |

| H112 | 83 | 34 | 20 | |

| 1060 | O | 72 | 21 | 30 |

| H112 | 6 8 | 17 | 18 | |

| 1070 | O | 73 | 17 | 33 |

| H112 | 75 | 24 | 24 | |

| 1100 | O | 89 | 29 | 34 |

| H14 | 130 | 110 | 6.7 | |

| H112 | 100 | 57 | 10 | |

| 1200 | O | 87 | 29 | 28 |

| H14 | 130 | 100 | 5.1 | |

| H112 | 90 | 35 | 17 | |

| 5083 | O | 300 | 140 | 17 |

| H32 | 330 | 240 | 9.8 | |

| H34 | 360 | 290 | 7.5 | |

| 6061 | T6 | 310 | 270 | 10 |

| T6511 | 290 | 270 | 9 | |

| 2024 | T3 | 480 | 320 | 15 |

- Fill with nickel gas (> 1.00Mpa) and keep the pressure for at least 30 minutes.

- Check if the pressure gauge drops. No leaks will be accepted.

- Keep pressure on for about 24 hours before delivery

- Bend test: Bend 180°0 with a bending radius of 25mm, no visible cracks.

- Flattening test: Flatten the pipe (the inner wall distance is the same as the wall thickness), and no obvious cracks should be found.

- Cleaning test: Clean the inner wall surface, no pollution was found, and the total impurity content was maintained at 5~60 mg/m 2

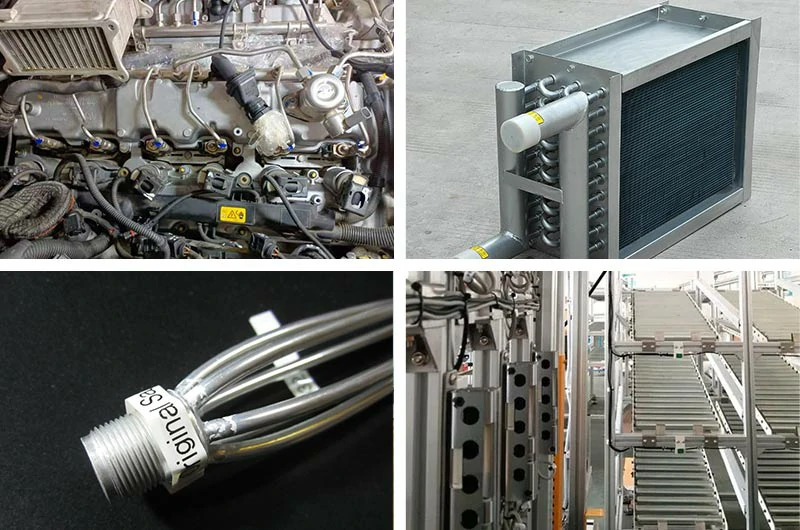

MASTAR aluminum coil tube industrial cooperation areas

- HVAC industry refrigerant pipes

- Air conditioning duct for mini split duct kit

- Car repair fuel line

- Evaporator and condenser tubes

- Gas stove connecting pipe

FAQ of aluminum coil tube product

What is aluminum coil pipe?

Aluminum alloy coil is a disc-shaped pipe made of aluminum alloy material, usually circular or spiral, and is commonly used as heat exchanger components in refrigeration systems and air-conditioning systems. This coil design gives it a larger surface area, which improves heat transfer efficiency, and allows more coils to be installed in a limited space, resulting in more efficient heat transfer.

What are the advantages of aluminum coil pipes?

- It has good flexibility when bending 360 degrees at will, corrosion resistance and high temperature resistance, good elongation and tensile strength, and can meet conventional processing requirements (stamping, stretching) and high forming ability;

- It has high plasticity, electrical conductivity and thermal conductivity, and can be gas welded, hydrogen welded and contact welded;

- Easy to withstand various pressure processing, stretching and bending.

- Corrosion resistance, strength and weldability ensure optimal performance over a long service life.

Why are aluminum coils mostly used in refrigeration systems and air conditioning systems?

- High heat transfer efficiency: The spiral shape of the coil increases the surface area, giving it higher heat transfer efficiency.

- Space saving: The compact design of the coil is suitable for installation in environments with limited space, such as inside buildings or machinery.

- Light weight: Aluminum alloy coil pipes are made of lightweight materials, making them easy to handle and install.

- Good corrosion resistance: Aluminum alloy has good corrosion resistance and is suitable for use in humid or corrosive environments.

Aluminum coil tube and copper coil tube?

- Heat transfer efficiency: Copper coils have a higher heat transfer coefficient and are suitable for environments that require efficient heat transfer, such as mechanical equipment.

- Corrosion risk: Aluminum coils are more susceptible to corrosion than copper coils, so anti-corrosion measures need to be taken when using aluminum coils.

- Ease of repair: Aluminum coils are generally easier to repair and damaged parts can be replaced.

- Weight and cost: Aluminum coils are lighter than copper coils and are suitable where overall weight needs to be reduced. While aluminum coils are cheaper to manufacture, copper coils last longer but cost more.

Choose MASTAR aluminum coil tube

- Fast delivery: We have extensive inventory to ensure fast delivery of any standard aluminum profile, saving time for the smooth progress of your project.

- Customized profiles: In addition to standard aluminum profiles, MASTAR can also provide customized aluminum profiles according to customer requirements for size and finish. You only need to indicate the alloy, length, quantity, surface finish, end use and other special requirements to us.

- High quality products: The quality of our products is in compliance with standards and certifications and features modern design, high hardness, bend resistance, rust resistance, and insect resistance.

- Competitive price: Our product prices are competitive and we can provide reasonable discounts for large quantities of products, allowing you to get more favorable prices and better services.

- After-sales support: We can provide fast after-sales support to ensure that you receive timely help and support when using our products.