Aluminum perforated tubes are widely used in the fields of construction, transportation, chemical industry, aviation, etc., and are favored for their light weight, corrosion resistance and good processability. In construction, aluminum perforated tubes are often used as decorative materials or sound-absorbing panels, while in the transportation and chemical industries, they are often used in exhaust and filtration systems.

Perforated aluminum tube product introduction

| Thickness | 0.4–15 mm |

| Tube Length | 10–6000 mm, or customized to your desired size |

| Outer Diameter | 6–200 mm |

| Hole Pattern | Round, rectangular, square, hexagonal, oval, star-shaped, etc. |

| Hole Diameter | 3–10 mm |

| Open Area | 23%–69% |

| Filtration Precision | 2–2000 μm |

| Welding Process | Spot welding or full welding, straight welding or spiral welding, argon arc welding |

| Surface Treatment | Electrolytic polishing, galvanizing, sandblasting, pickling, passivation |

| Frame Structure | With margins or without margins |

| Packaging | Moisture-proof paper, pallets, wooden containers |

Round hole aluminum perforated tube

- Pore diameter: 3–10 mm

- Thickness: 0.4–15 mm

- Open area: 23%–69%

- Common alloys: 1100, 3003, 5052

- Applications: air conditioning ventilation systems and air purification devices, building ventilation windows, ceiling decorations, etc.

Square hole aluminum perforated tube

- Aperture: 5–15 mm

- Thickness: 1–10 mm

- Open area: 30%–50%

- Common alloys: 1100, 3003, 6061

- Applications: Agricultural or construction material screening, indoor and outdoor decoration, such as partitions, lampshades, etc.

Slotted hole aluminum perforated tube

- Pore diameter: 2–8 mm (slot width)

- Thickness: 0.5–5 mm

- Open area: 20%–45%

- Common alloys: 5052, 6061, 7075

- Applications: Water treatment and drainage systems, liquid and oil filtration, suitable for chemical and pharmaceutical industries.

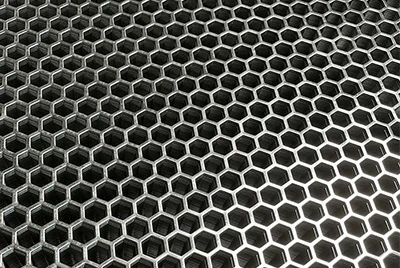

Hexagonal hole aluminum perforated tube

- Aperture: 3–10 mm

- Thickness: 1–10 mm

- Open area: 30%–60%

- Common alloys: 3003, 7075

- Applications: facade decoration, noise barriers, and can also be used for equipment protection covers to prevent debris from entering.

Fish scale hole perforated aluminum tube

- Aperture: 3–8 mm

- Thickness: 0.5–2 mm

- Open area: 20%–40%

- Common alloys: 3003, 5052

- Applications: Grain storage requires a low temperature and dry environment, and fish scale hole perforated pipes can be used as ventilation wall structures in warehouses.

Aluminum perforated tube with special-shaped holes (such as oval and plum blossom holes)

- Pore diameter: 5–15 mm (depending on shape)

- Thickness: 1–8 mm

- Open area: 15%–40%

- Common alloys: 3003, 5052, 6061

- Applications: Used in garden decoration, landscape design, automotive exhaust pipes and muffler parts.

Advantages of perforated aluminum tube

- Ventilation and heat dissipation: The perforated design promotes air circulation and helps in internal heat dissipation of equipment and pipes, suitable for occasions requiring temperature control.

- Lightweight without losing strength: Compared with solid aluminum pipes, perforated aluminum pipes are lighter and do not significantly affect the structural strength, making the use of materials more economical.

- Noise reduction function: Perforations can effectively reduce airflow noise and are often used in mufflers and ventilation systems to reduce aerodynamic noise.

- Filtration function: It can block larger particles of impurities and is used as a simple filtering device to prevent foreign matter from entering the system.

- Decorative effect: Modern and beautiful appearance, suitable for architectural decoration, adding visual value to the structure.

Perforated aluminum tube Vs stainless steel perforated tube

| Comparison Item | Aluminum Perforated Tube | Stainless Steel Perforated Tube |

| Weight | Lightweight, easy to install and transport | Heavier, increasing transportation and installation costs |

| Corrosion Resistance | Good oxidation resistance, but not as good as stainless steel in certain environments | Excellent corrosion resistance, suitable for harsher environments |

| Strength | Lower strength, suitable for medium to low-strength applications | High strength, suitable for bearing greater loads |

| Thermal Conductivity | Excellent, suitable for applications requiring heat conduction | Poor thermal conductivity |

| Cost | Lower cost, high cost-performance ratio | Higher cost, usually used in demanding applications |

| Workability | Easy to process, suitable for various forming and surface treatment techniques | More challenging to process, typically requires more specialized equipment |

| Appearance | Various surface treatments available, diverse appearance | High gloss, good texture |

| Environmental Impact | Fully recyclable, energy-saving and environmentally friendly | Recyclable, but with higher energy consumption |

Aluminum perforated tubes are suitable for lightweight and cost-sensitive applications, while stainless steel perforated tubes are more suitable for environments with high strength and corrosion resistance requirements.

Welding method of perforated aluminum tube

Direct welding

- Direct welding is the most common production process for perforated aluminum tubes, and usually has the following characteristics:

- Straight weld: The straight welding process welds along the longitudinal direction of the aluminum tube, and the weld is distributed in a straight line, with a simple and uniform structure.

- Fast production speed: The straight welding process is formed in one step during the production process, with high efficiency and suitable for mass production.

- Good stability: Since the straight weld does not bend around, the stability and pressure resistance of the pipeline are strong, which is suitable for scenes with high pressure requirements.

- Low cost: The process is simple, the cost of welding equipment is low, and it is suitable for economical projects.

Spiral welding

Features of spiral welded perforated aluminum pipe:

- Spiral weld: The weld is spirally wound on the surface of the aluminum pipe, which enhances the structural strength and flexibility of the pipe.

- Stronger pressure resistance: The spiral weld improves the pressure resistance of the pipe through multi-layer welding, making it less likely to deform under high pressure.

- Strong adaptability: The spiral structure has a good bearing capacity for irregular pressure and is suitable for fields with higher requirements for pipeline stability.

- Higher production cost: The spiral welding process is relatively complex and the welding speed is slow, which is usually suitable for projects with high performance requirements.

Perforated aluminum tube FAQ

What is the temperature range of aluminum perforated pipes?

Aluminum perforated pipes perform well at low temperatures, but their strength may be reduced in high temperature environments above 400°F (about 204°C).

Can perforated aluminum pipes be used outdoors?

Yes, but it is recommended to choose 5052, 6061, 6063 corrosion-resistant alloys and anodize to extend service life.

How to choose the right aperture?

Choose a larger aperture and open area according to ventilation or filtration needs to ensure smooth air or liquid flow.

Can perforation patterns be customized on demand?

Mastar supports a variety of customized hole types, such as fish scale holes, hexagonal holes, etc., which can be customized on demand.

Mastar perforated aluminum tube buying guide

As a high-quality supplier of aluminum products, Mastar provides you with a variety of specifications, materials and perforation designs of aluminum tubes to help you find the perforated aluminum tube that best suits your project needs. The following are some important factors when purchasing for your reference.

Understand your application needs

To choose the right perforated aluminum tube, you must first clarify its purpose and environmental requirements:

Ventilation and heat dissipation: For systems that require air circulation or temperature control, it is recommended to choose perforated aluminum tubes with uniform hole spacing and reasonable hole diameter.

Noise reduction requirements: In silencers or ventilation systems, perforated aluminum tubes can effectively reduce airflow noise.

Decorative requirements: If it is used for construction or decoration projects, you can choose modern hole patterns and surface treatments to enhance the visual effect.

Choose the right specifications and sizes

The size and specifications of perforated aluminum tubes will affect their application effects. Mastar supplies perforated aluminum tubes of various specifications. You can consider the following aspects:

Outer diameter and wall thickness: Choose the appropriate outer diameter and wall thickness to meet the structural strength and lightweight requirements.

Aperture and hole spacing: Different hole diameters and hole spacing are suitable for different application scenarios. Mastar can provide a variety of standard hole types to ensure that the product meets your design requirements.

Material selection and surface treatment

Aluminum alloy material and surface treatment directly affect the performance and life of perforated tubes. Common materials include 6061, 5052 and other aluminum alloys with moderate corrosion resistance and strength. Mastar can provide a variety of alloy options:

Anodizing: Improves corrosion resistance, suitable for outdoor and humid environments.

Powder coating: Increases decorativeness and wear resistance, suitable for applications with high visual requirements.

Professional support and personalized customization

Mastar not only provides perforated aluminum tubes of standard specifications, but also provides personalized customization services according to your needs. Our team will discuss the specific requirements of product applications with you and recommend suitable product types and specifications for you. At the same time, we can assist customers with sample selection and fast delivery to ensure that you get a high-quality service experience during the project implementation.

Inventory and delivery services considering long-term cooperation

As a supplier, Mastar can flexibly respond to the procurement plans of different customers and provide long-term inventory and stable delivery services. We have a diverse product inventory and support efficient logistics solutions to help customers reduce inventory management pressure during the project cycle.