Our aluminum profiles are preferred for swimming pool construction due to their excellent quality and durability. In particular, our anodizing technology extends up to 13 meters in length, significantly enhancing corrosion resistance and lifespan. This provides a stable and aesthetically pleasing structural assurance for swimming pools.

Mastar provides aluminum profiles for constructing modular swimming pools, including fixed and movable components, as well as any other accessories. We offer a variety of alloy materials and can meet your surface finish requirements. For technical assistance, please contact us.

Common types of aluminum swimming pools

Aluminum above ground pools

Aluminum above ground pools- Using corrosion-resistant aluminum alloys like 6061, our structures are lightweight and easy to install, making them ideal for home backyards. Aluminum's lightweight nature combined with its high strength allows it to withstand significant water pressure.

Extruded aluminum inground pools

Extruded aluminum inground pools- Usually constructed using 6063 and 5052 aluminum alloys, these are buried underground, providing a stable and durable swimming experience. They are suitable for long-term use in both private and commercial swimming pools, offering excellent corrosion resistance.

Aluminum semi inground pool

Aluminum semi inground pool- Combining the advantages of both above-ground and underground swimming pools, commonly using 5052 aluminum alloy, with some portions embedded underground for stability. This construction method offers flexibility in installation, making it suitable for uneven terrain and providing diverse design options.

Aluminum saltwater swimming pool

Aluminum saltwater swimming pool- Constructed from highly corrosion-resistant aluminum alloys, such as 5052 alloy, specifically designed for saltwater environments to withstand corrosion from seawater. Aluminum is lightweight yet strong, making it suitable for coastal areas and beach resorts.

Aluminum swimming pool components

Extruded aluminum locking walls

Extruded aluminum locking walls- Extruded aluminum lock walls combine the rigidity and toughness needed for underground swimming pools, leveraging aluminum's corrosion resistance. The unique interlocking system significantly enhances pool strength, suitable for various types such as underground, semi-underground, and above-ground pools.

- Recommended alloys: 5A02, 5052

Extruded aluminum columns

Extruded aluminum columns- Aluminum columns serve as the primary support structure for swimming pools, ensuring stability of the pool walls and roof while effectively resisting seismic and other external forces, thereby enhancing pool safety.

- Recommended alloy: 6063

Extruded aluminum roof cover

Extruded aluminum roof cover- Aluminum roof covers, treated with anodization or colored coating, exhibit strong corrosion resistance. Embossing can be applied for non-slip properties, often used as a walkable deck surface.

- Recommended alloys: 3003, 5052

Extruded aluminum track

Extruded aluminum track- The main role of aluminum bottom tracks is to provide foundational support for swimming pool wall panels. By using bottom tracks, the wall panels are securely fixed together, forming a cohesive pool wall structure and ensuring overall stability.

- Recommended alloys: 6061, 6063

Pool drainage aluminum pipes

Pool drainage aluminum pipes- Pool drainage aluminum pipes, corrosion-resistant and robust, ensure efficient water discharge and circulation, facilitating easy installation and maintenance while preventing poolside water accumulation for enhanced safety.

- Recommended alloys: 3A21, 6A02, 6063

Extruded aluminum fasteners

Extruded aluminum fasteners- All fasteners and hardware used in the pool are aluminum, connecting and securing components to prevent rust or corrosion.

- Recommended alloy: 6063

Aluminum profiles for swimming pool surroundings

Aluminum swimming pool ladders

Aluminum swimming pool ladders- Aluminum swimming pool ladder offers safe, convenient entry and exit with lightweight, corrosion-resistant high-strength alloy. Anti-slip steps and handrail ensure safety, easy cleaning, and maintenance, enhancing aesthetics.

- Recommended alloys: 5083, 6061, 6063

Aluminum pool deck

Aluminum pool deck- Aluminum pool deck provides a safe, comfortable walking area with corrosion-resistant alloy, anti-slip properties, and easy maintenance. Anodizing or powder coating enhances durability and aesthetics.

- Recommended alloy: 6061, 6063

Aluminum pool deck railing

Aluminum pool deck railing- Aluminum pool deck railing is made from corrosion-resistant aluminum alloy, providing reliable safety protection against accidental falls while enhancing the aesthetic appeal around the pool.

- Recommended alloys: 5052, 6061

Popular sizes of aluminum swimming pools

Here are the common popular sizes for aluminum swimming pools, typically with heights of 52" or 54", and they can also be customized according to customer requirements.

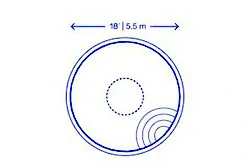

- 18' aluminum round pool

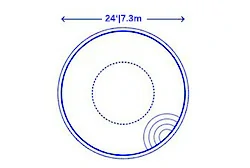

- 24' round aluminum pool

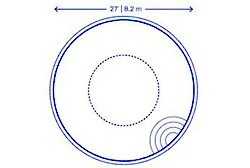

- 27' round aluminum pool

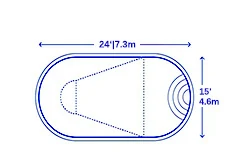

- 15' x 24' aluminum oval pool

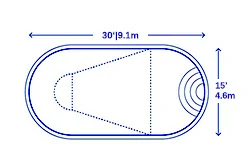

- 15' x 30' aluminum oval pool

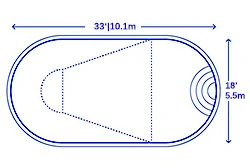

- 18' x 33' aluminum oval pool

Advantages of Mastar aluminum swimming pools

- Durability: Aluminum is highly rust-resistant and corrosion-resistant, ensuring your pool remains in good condition even after years of exposure to water and chemicals.

- Strength: Despite being lightweight, aluminum exhibits remarkable strength, capable of bearing significant loads and pressures without deformation.

- Low maintenance: Compared to other materials, aluminum swimming pools require less maintenance. Its natural corrosion resistance means lower frequency of repairs or replacements.

- Aesthetic appeal: Aluminum swimming pools can be designed with sleek, modern lines, enhancing the overall appearance of your backyard. They can also be finished according to your aesthetic preferences.

- Environmentally friendly: Aluminum is recyclable, making aluminum swimming pools an environmentally responsible choice. Using recycled aluminum reduces the carbon footprint of manufacturing new materials.

- Quick installation: Due to its lightweight nature, aluminum pools are easier and quicker to install, significantly reducing installation time and labor costs.

Aluminum swimming pools vs steel swimming pools

| Feature | Aluminum Pool | Steel Pool |

| Durability | Highly durable and can last for many years without significant wear and tear. | Durable but may be prone to rust and corrosion over time, especially in harsh climates. |

| Resistance to rust | Resistant to rust and corrosion, making it ideal for all climates. | Prone to rust and corrosion, especially in humid or salty environments. |

| Weight | Lightweight, making it easier to install and move. | Heavier, which may require more effort and cost for installation and transportation. |

| Cost | Generally more expensive due to the material properties and benefits. | Usually less expensive than aluminum pools. |

| Maintenance | Low maintenance due to its resistance to rust and corrosion. | Requires regular maintenance to prevent rust and corrosion. |

| Appearance | Often has a more modern and sleek appearance. | May have a more traditional look but can be coated or painted for different aesthetics. |

| Heat conductivity | Lower heat conductivity, keeping pool water cooler. | Higher heat conductivity, which can warm pool water faster in sunny conditions. |

Master aluminum pool installation guide

1.Excavate, level, and prepare the pool site. Lay a 2-inch thick layer of stone dust as a base, compact it, and check for levelness. If the height difference along all edges is within 1/2 inch, proceed to the next step.

2.Assemble the pool frame and recheck the levelness around the pool perimeter. Place patio blocks under the frame to ensure levelness.

3.Bring in the sand for the pool bottom. Spread it as evenly as possible, wet it thoroughly, and compact it. Wet it again before installing the liner.

4.Install the liner and continue filling with water.

5.Backfill around the pool. For fully inground pools, it is recommended to wait 6 weeks before installing decking around the pool. This allows the ground to settle naturally and prevents sinking.

6.Finish the surroundings according to your preferences and enjoy your new pool!