Aluminum is known for its lightweight and durable properties, and it has reshaped the ski industry by enhancing performance and durability. Traditionally, skis were primarily made of wood, offering flexibility and responsiveness. However, as skiing has evolved into various disciplines such as freestyle skiing, speed skiing, and cross-country skiing, the demand for stronger, lighter, and more versatile equipment has surged.

Components of aluminum skis

Load-bearing components of skis

Load-bearing components of skis- Load-bearing components of skis refer to the key parts that withstand forces and pressures during skiing. Their design and material selection directly impact the performance, stability, and durability of the skis.

- Alloy:7075, 7178

Aluminum ski edges

Aluminum ski edges- Aluminum ski edges refer to the edges of skis made from aluminum material, reducing overall weight while still providing sufficient grip and control.

- Alloy:7075, 7178

Ski tail protector

Ski tail protector- The ski tail protector is a component installed at the tail of the ski, using aluminum alloy to provide stronger protection for the ski's tail.

- Alloy:6061

Ski side protector

Ski side protector- Ski side guards are components located on both sides of the ski, connecting the top surface and edges. Made from aluminum alloy, they provide additional lateral support and stability, enhancing the skiing experience.

- Alloy:7178

Ski base protector

Ski base protector- The ski base protector is a protective device installed on the bottom of skis. An aluminum alloy base protector effectively safeguards the ski base, maintaining its smoothness and integrity, which helps enhance speed and smoothness during skiing.

- Alloy:5052

Ski shell

Ski shell- The ski shell is a protective outer covering for skis, safeguarding the internal structure and enhancing aesthetics. An aluminum alloy shell is used for high-performance skis to increase rigidity and durability.

- Alloy:ADC6, ADC12

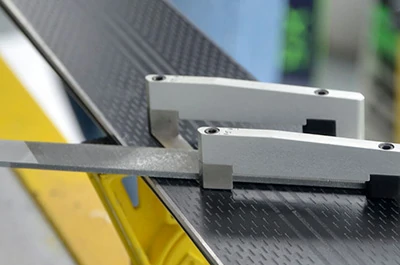

Belt structural components

Belt structural components- Aluminum alloy belt structural components refer to high-performance fasteners used on ski bindings, primarily made from aluminum alloy for securing and adjusting ski straps.

- Alloy:ADC6, ADC12

Advantages of using aluminum in skis

- Lightweight: Aluminum's low weight helps reduce the overall weight of skis, enhancing maneuverability and flexibility, allowing skiers to perform actions and turns more easily.

- High strength: Aluminum offers high strength and rigidity, enhancing the structural stability and durability of skis, suitable for various demanding skiing environments.

- Corrosion resistance: Aluminum exhibits excellent corrosion resistance, especially in wet and snowy conditions, preventing damage from moisture and salt exposure, thereby prolonging the lifespan of skis.

- Shock absorption: Aluminum's inherent damping properties effectively absorb vibrations generated during skiing, providing a smoother and more comfortable skiing experience.

- Environmental Friendliness: Aluminum is recyclable, making its manufacturing and recycling processes relatively environmentally friendly, reducing consumption of natural resources and environmental impact.

- Cost-effectiveness: Compared to some high-performance materials like carbon fiber, aluminum is lower in cost with mature manufacturing processes, offering excellent performance at a more economical price.

Aluminum ski boards vs. carbon fiber ski boards

- Lightweight

- High strength

- Excellent durability

- Naturally corrosion-resistant, suitable for all environments

- Mid-price, suitable for most skiers

- Various skiing scenarios, such as all-around skiing and racing skiing

- Requires regular inspection and maintenance to maintain optimal performance

- Aluminum alloy is recyclable

- Lighter weight

- Higher strength

- Good durability, but risk of cracking under extreme impact

- Corrosion resistant, but beware of extreme environments

- High price, suitable for professional and advanced skiers

- Suitable for competitive skiing, high-speed skiing and technical skiing

- High maintenance requirements, especially in extreme conditions

- The carbon fiber production process is energy-intensive and difficult to recycle

The development prospects of aluminum skis?

Improved strength and durability: with the advancement of material technology and the improvement of processes, aluminum skis can further enhance their structural strength and impact resistance, extend their service life, and reduce maintenance costs in the future.

Enhanced environmental awareness: aluminum alloy is a recyclable material. In the future, society's emphasis on environmental protection will promote the production and use of aluminum skis, reduce the consumption of natural resources, and conform to the trend of sustainable development.

Driven by technological innovation: aluminum skis can achieve better performance improvement and user experience through the introduction of new materials, optimization of structural design, and innovation of production processes, and meet the needs of ski enthusiasts for high performance and safety.

Market demand growth: the popularity of skiing and the growth of market demand will provide strong support for the development of aluminum skis. Consumers' preference for lightweight, durable, and environmentally friendly ski equipment will prompt manufacturers to continuously innovate and improve their products.

Why choose Mastar?

- We provide a variety of aluminum alloy grades and specifications to meet the manufacturing needs of various types of snowboards.

- We have abundant inventory and provide aluminum accessories of various sizes, with fast delivery, and urgent orders will not delay production.

- The quality of aluminum is guaranteed, and various quality inspection reports can be issued to make customers buy with confidence.

- Professional pre-sales service, professional team, give customers detailed quotations and technical support.

- Timely after-sales service, quickly respond to customer feedback, provide effective solutions, and ensure customer satisfaction.