7075 aluminum bar rods are the top choice for aerospace, military, mold making, and automotive industries due to their exceptional strength, hardness, and corrosion resistance. MASTAR offers a variety of tempers including T6, T651, T73, T7351, T73511, and T6511, as well as shapes like square, flat, and round bars to meet diverse needs.

By choosing MASTAR as your supplier, you'll benefit from our extensive inventory, fast delivery times, and expert technical support, ensuring you receive the highest quality 7075 aluminum rods to help your project succeed.

Product catalogue of MASTAR 7075 aluminum bar rod

- 7075 aluminum round bar——high strength & high precision

Available size: Φ5mm-Φ350mm diameter; 1000mm-6000mm length

View [detailed information & inventory of 7075 aluminum round bars]

- 7075 aluminum square bar——high structural stability

Available size: 5*5-200*200 mm thickness; 1000mm-6000mm length

- 7075 aluminum rectangular bar——excellent machinability

Available size: 2mm-100mm Thickness; 1000mm-6000mm length

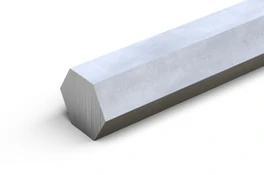

- 7075 aluminum hex bar——high fatigue resistance and wear durability

Available size: 5mm-200mm thickness; 1000mm-6000mm length

- 7075 angle bar——high strength and durability

Known for its exceptional strength and fatigue resistance, widely used in demanding engineering and structural applications.

- 7075 extruded T6511/T73511 bar

Extruded 7075 aluminum bar combines high strength, durability, and reliability, making them an ideal choice for various demanding industrial applications.

- 7075 aluminum billet——high strength and premium quality material

Available size: the diameter up to 1350mm

- 7075 aluminum forged bar——precision forged with exceptional mechanical properties

Available size: 200 to 1000mm diameter;

MASTAR 7075 aluminum bar rod stock temper and performance

7075 aluminum rods are commonly produced through cold drawing or extrusion. When purchasing 7075, it's crucial to understand the temper as each one has different mechanical properties that can significantly impact the final application.

| Detailed Temper and Performance Analysis | |||||

| Stock temper | Description | Tensile Strength MPa | Yield Strength MPa | Elongation at Break % | Usage Scenario |

| 7075-T6 Aluminum Rod | Solution heat-treated → Artificial aging | 560 | 480 | 7.9 | |

| 7075-T651 Aluminum Rod | Solution heat-treated → Stress-relieved → Artificial aging | 550 | 460 | 8.2 | High-strength structural applications |

| 7075-T6511 Aluminum Rod | Solution heat-treated → Stress-relieved → Artificial aging → Light straightening | 580 | 510 | 5.6 | Machining and rolled bars |

| 7075-T73 Aluminum Rod | Solution heat-treated → Special artificial aging | 500 | 410 | 7.1 | Extruded bars and shapes in T6 condition |

| 7075-T7351 Aluminum Rod | Solution heat-treated → Special artificial aging | 510 | 410 | 7.5 | Stress corrosion resistance |

| 7075-T73511 Aluminum Rod | Solution heat-treated → Stress-relieved → Special artificial aging → Light straightening | 510 | 420 | 8.0 | Stress corrosion resistance + Stress relief |

| 7075-T76510 Aluminum Rod | Solution heat-treated → Multi-step artificial aging for optimized performance | 570 | 490 | 6.8 | Stress corrosion resistance + Light straightening |

| 7075-T76511 Aluminum Rod | Solution heat-treated → Stress-relieved → Multi-step artificial aging → Light straightening | 560 | 500 | 6.7 | Fatigue resistance and toughness + Light straightening |

MASTAR 7075 aluminum bar rod specification

| Temper | 7075 cold finish specification | 7075 extruded specifications |

| 7075-T6 Cold finish/Extruded | QQA-225/9, AMS QQA-225/9, ASTM B-211, AMS 4122 | AMS 4154 AMS 4122 |

| 7075 T651 Cold finish | QQA-225/9, AMS QQA-225/9, ASTM B-211, AMS 4123 | - |

| 7075-T6511 Extruded | - | QQA-200/11, AMS QQA-200/11, ASTM B-221, AMS 4169 |

| 7075 T73 Cold finish/Extruded | QQA-225/9, AMS QQA-225/9, Chem only to: ASTM B-211, AMS 4122 | AMS 4166 |

| 7075 T7351 Cold finish | QQA-225/9, AMS QQA-225/9, Chem only to: ASTM B-211, AMS 4124 | - |

| 7075-T73511 Extruded | - | QQA-200/11, AMS QQA-200/11, ASTM B-221, AMS 4167 |

| 7075 T76510 Extruded | - | AMS 4168 |

| 7075 T76511 Extruded | - | AMS 4169 |

How MASTAR 7075 Aluminum bar rods meet the performance requirements of various industries

MASTAR aerospace-grade 7075 aluminum bar rod

Mastar Aerospace-Grade 7075 Aluminum Rods are trusted by key industry partners, including Collins Aerospace, Boeing, Airbus, Air Industries Group, Airframer, and The Alinabal Group of Companies. Quick Quote

- Airframe components: aircraft frames, wing spars, and other load-bearing parts.

- Engine components: turbine blades and engine mounts.

- Landing gear parts: landing gear struts and shock absorber assemblies.

- Connectors and fasteners: aerospace connectors, bolts, and nuts.

- Strength: must meet high-strength requirements according to aviation standards to ensure the safety of aircraft structures.

- Corrosion resistance: excellent resistance to corrosion, protecting against environmental and flight-related corrosive factors.

- Weight: lightweight is crucial in aviation, aiming to reduce weight as much as possible while maintaining strength.

- Machining precision: high-precision machining ensures that parts meet the strict dimensional and tolerance requirements of aviation regulations.

MASTAR military grade 7075 aluminum bar rod

MASTAR military-grade 7075 aluminum bar rods have key partnerships with industry leaders including UKROBORONPROM, ASELSAN, HEAVY INDUSTRIES TAXILA, Raytheon Company, SF Enginnering, Aselsan AS, HEAVY INSUSTRIES TAXILA…Quick Quote

- Airframe components: artillery parts, missile launch tubes.

- Armor structures: tank armor plates and protective structures.

- Military vehicle structural parts: frames and chassis of military vehicles.

- Communication equipment: military antennas and communication equipment mounts.

- Strength and wear resistance: high strength and wear resistance to meet the demands of weapon systems and protective gear.

- Stability: consistent material performance in extreme environments, including high and low temperatures and vibrations.

- Impact resistance: components can withstand significant impact forces without cracking or deformation.

- Machining quality: precise machining and forming to ensure parts meet military standards and performance requirements.

MASTAR 7075 bar rod for mold and tooling manufacturing

MASTAR 7075 Mold Plate offers quality comparable to renowned products like Mic-6, ACP5080, ACP5080R, Alca5™, ATP5™, and C520. It is widely used in the mold and tooling industry. Quick Quote

- Mold bases: plastic injection mold cavities and stamping mold cavities.

- Mold cavities: tank armor plates and protective structures.

- Mold accessories: mold support pillars and guide pillars.

- Mold frames: mold frames and frame components.

- Machinability: excellent machinability is crucial to ensure the complex shapes and precision of molds.

- Hardness: high hardness extends the mold's lifespan and reduces wear.

- Stability: strong material stability prolongs the mold's life while maintaining accuracy.

MASTAR 7075 aluminum bar rod for auto industry

MASTAR 7075 aluminum rods are partnered with top automotive companies such as Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile…Quick Quote

- Body structure components: frames and chassis structures.

- Suspension system parts: suspension brackets and arms.

- Powertrain components: drive shafts and transmission mounts.

- Wheel components: hubs and spokes.

- Strength and impact resistance: high strength and good impact toughness ensure vehicle components' safety during operation.

- Lightweight: reduces vehicle weight, enhancing fuel efficiency and dynamic performance.

- Corrosion resistance: excellent resistance to corrosion under various environmental conditions, especially for external components.

- Machining precision: high precision of aluminum rods improves the accuracy of automotive parts, ensuring proper assembly and performance.

MASTAR 7075 aluminum bar rod for sports

MASTAR 7075 aluminum bar rods are trusted by high-end racing vehicle manufacturers and premium climbing and skiing equipment producers. Our products are well-regarded for their performance and reliability in the sports equipment industry. Quick Quote

- Bicycle components: bike frames and handlebars.

- Climbing gear: trekking poles and climbing protection gear.

- Ski equipment: ski poles and ski binding components.

- Fitness equipment: exercise machine frames and weightlifting gear.

- Strength and lightweight: provides high strength while minimizing weight to enhance the performance of sports equipment.

- Durability: resists wear and impact from frequent use.

- Aesthetics: the appearance of sports equipment is also crucial; mastar offers anodized and various color-coated finishes to support your project.

Why is MASTAR the Preferred Supplier in Numerous Industrial Sectors?

- Fast delivery: we maintain a large inventory to ensure quick shipping of any product, saving you time on your projects.

- Customization services: Mastar offers tailored services based on your needs. just specify the length, quantity, surface finish, cutting, bending, color coating, end use, and other special requirements.

- Competitive pricing: our product prices are competitive, with reasonable discounts for bulk orders, ensuring you receive the best value and quality.

- After-sales support: we provide prompt after-sales support to ensure you receive timely assistance and support while using our products.

MASTAR one-stop solution for 7075 aluminum alloy products

- 7075 aluminum plate

- 7075 aluminum tube

- 7075 aluminum flat bar

MASTAR other hot selling aluminum bar products

- 2024 aluminum bar

- 6061 aluminum bar

- 7050 aluminum bar

- 2219 aluminum bar

- 2618 aluminum bar

- 6082 aluminum bar

7075 aluminum bar rod resource knowledge center

1.Comparative characteristic of different 7075 aluminum bar tempers

General temperGeneral corrosion resistanceMachinabilityAnodizing responseStress corrosion

| General temper | General corrosion resistance | Machinability | Anodizing response | Stress corrosion |

| T6000 temper | C | C | B | C |

| T7000 temper | C | C | B | B |

2.7075 vs 2024

Both have high strength and are commonly used in aerospace and high-stress structural applications. They both offer excellent machinability, making them suitable for precision components. However, there are subtle differences in composition, performance, and applications:

- 7075 primarily contains zinc as its main alloying element, while 2024 primarily contains copper.

- 7075 has better corrosion resistance, whereas 2024 exhibits weaker corrosion resistance.

- 7075 offers higher fatigue strength, making it suitable for applications requiring high fatigue performance. 2024 has relatively lower fatigue strength.

- 7075 is commonly used in high-strength and high-fatigue-strength applications, such as aerospace structural components. 2024 is often used in parts requiring high strength and good machinability, such as aircraft frames and aerospace components.

3.7075 vs 6061

Both are widely used in aerospace, automotive, and other industries. They both offer excellent machinability, making them easy to cut and process. However, there are subtle differences in composition and performance:

- 7075 primarily consists of zinc as its alloying element, whereas 6061 primarily contains magnesium and silicon.

- 7075 has higher strength, making it more suitable for high-stress applications, while 6061 has lower strength but maintains a good balance between strength and toughness.

- 6061 offers better corrosion resistance than 7075, especially in marine environments.

- 6061 has better weldability compared to 7075, making it more suitable for structural applications that require welding.

4.7075 vs 7050

Both alloys exhibit very high strength and are commonly used in high-stress applications, such as the aerospace industry. Both have zinc as their primary alloying element and share similar chemical compositions. However, there are subtle differences in their performance and applications:

- Corrosion Resistance: 7050 offers better corrosion resistance than 7075, making it more suitable for environments requiring high resistance to corrosion.

- Crack Resistance: 7050 has superior crack resistance and stress corrosion cracking properties compared to 7075, making it ideal for applications that demand high reliability.

- Cost: The manufacturing cost of 7050 is generally higher than 7075, but its superior characteristics provide advantages in specific applications.

5.Weldability of 7075 aluminum rods

7075 aluminum rods, widely recognized for their exceptional strength, hardness, and corrosion resistance, offer irreplaceable advantages in aerospace, military, mold manufacturing, and automotive industries.

However, the weldability of 7075 aluminum rods is limited, making them unsuitable for effective welding using arc welding techniques. This poses a challenge for many welders, as the welding process can easily lead to cracks and other defects, reducing the strength and reliability of the joints.

6.Which is stronger: 7075 aluminum or 304 stainless steel?

7075 is a zinc-containing aluminum alloy known for its strength, durability, good fatigue resistance, and average machinability. The maximum tensile strength of 7075 grade aluminum is greater than 572 MPa, with a density of 2.8 g/cm³. In comparison, 304 stainless steel has a density of 8 g/cm³ and a tensile strength of 621 MPa.

This means that 7075 aluminum has about 90% of the strength of 304 stainless steel while weighing only one-third of it. Therefore, for the same weight, 7075 aluminum provides nearly three times the strength of 304 stainless steel components.