As a supplier of aluminum sign frames, we provide high-strength, easy-to-assemble aluminum extrusions for sign frames.

Our products are diverse, offering options with or without fasteners, and support customized sizes along with anodizing and mill finish surface treatments.

Standards: EN 12020-2, EN 755, EN 573, ASTM B221, AA-M12, ISO 7599

Surface Treatments: Mill Finish, Anodizing, Powder Coating, Electrophoretic Coating

Alloy selection for aluminium sign frame extrusions

We recommend using 6063 and 6005 aluminum alloys for sign frame materials due to their excellent strength and durability.

If your project has high strength requirements, we suggest using 6061 aluminum alloy.

Of course, we also offer customization services for other alloys such as 6082 and 6060.

Recommended sizes for aluminium sign frame extrusions

- Wall Thickness: 0.4-3.5 mm (1/64″ - 1/8″)

- Length: 1-6 m (3' - 20')

- Cross-Section Dimensions: Customizable according to drawings

Thickness will affect various performance and durability aspects of aluminum sign frame extrusions. We recommend a standard wall thickness of 0.8 mm.

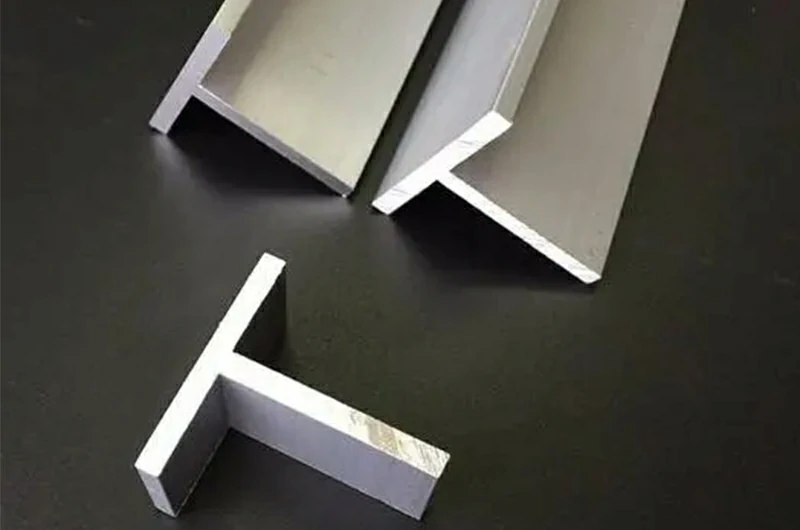

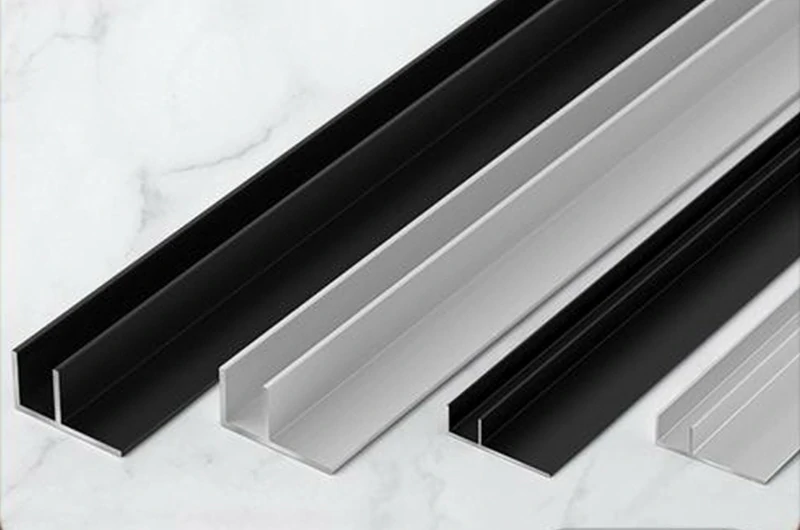

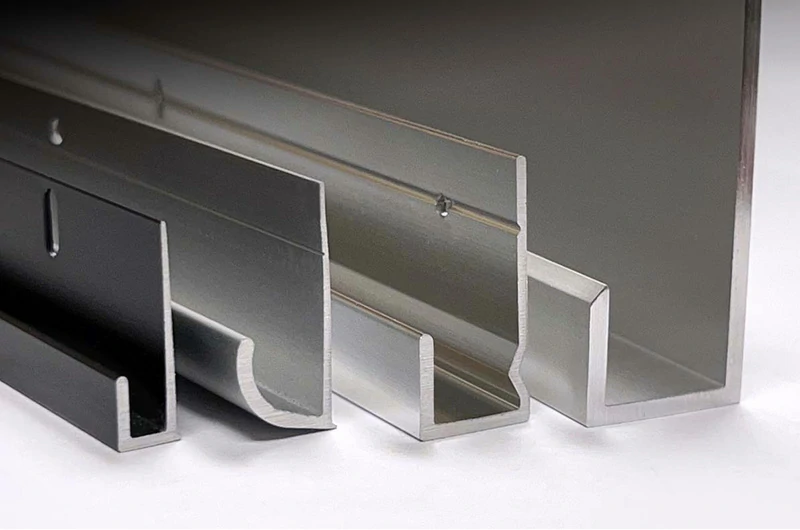

Popular products of aluminium sign frame extrusions

We offer aluminum sign frame extrusions in various sizes, with or without fasteners.

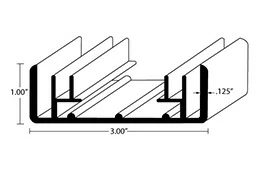

Aluminum Sign Channe

Aluminum Sign Channe1″ x 3″ Sign Channel

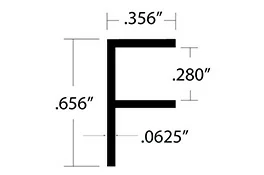

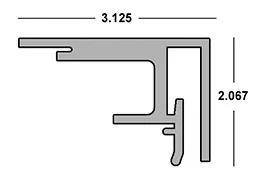

Aluminum Sign "F" Channel

Aluminum Sign "F" Channel.656″ x .356″ for 1/4″ Material

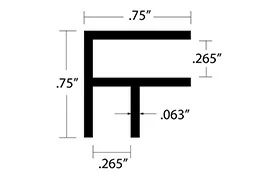

Aluminum Sign Out Corner

Aluminum Sign Out Corner3/4″ x 3/4″ for 1/4″ Material

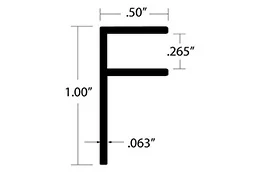

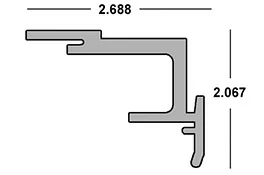

Aluminum Sign "F" Channel

Aluminum Sign "F" Channel1″ x .500″ for 1/4″ Material

Aluminum Sign "F" track

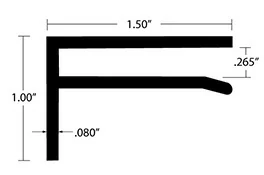

Aluminum Sign "F" track1-1/2″ x 1″ for .265″ Material

Aluminum Sign "F" track

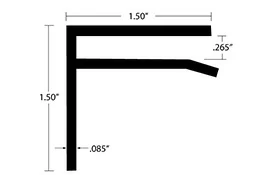

Aluminum Sign "F" track1-1/2″ x 1-1/2″ for .265″ Material

Aluminum Sign "H" Divider

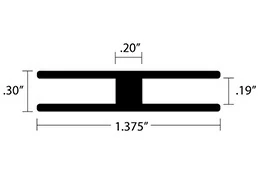

Aluminum Sign "H" Divider1-3/8″ for 3/16″ Material

Aluminum Sign "H" Divider

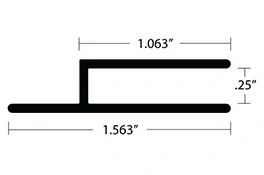

Aluminum Sign "H" Divider1-9/16″ Long Leg x 1-1/16″ Short Leg for 1/4″ Material

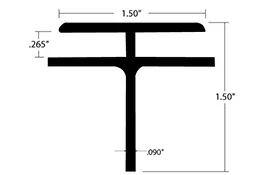

Aluminum Sign "T" Divider

Aluminum Sign "T" Divider1-1/2″ x 1-1/2″ for .265″ Material

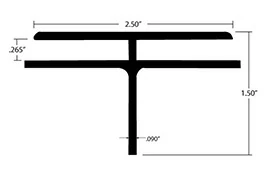

Aluminum Sign "T" Divider

Aluminum Sign "T" Divider2-1/2″ x 1-1/2″ for .265″ Material

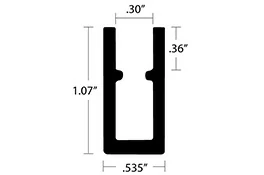

Aluminum Sign Channel

Aluminum Sign ChannelFraming – 1.070″ Legs x .535″ OD x .300″ ID

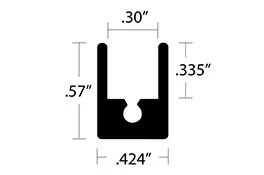

Aluminum Sign Channel

Aluminum Sign Channel.570″ x .424″ w/ Screw port for .300″ Material

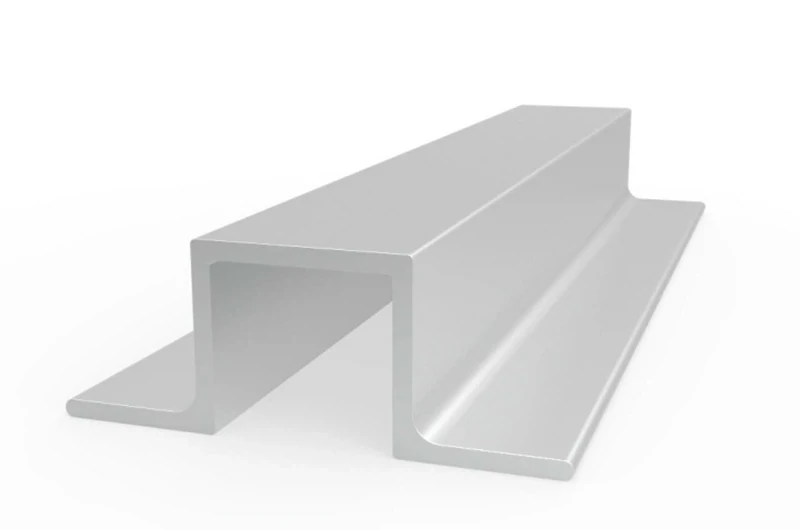

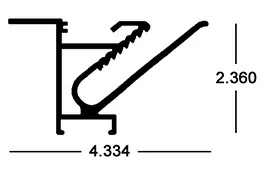

Sign Frame With Retainer

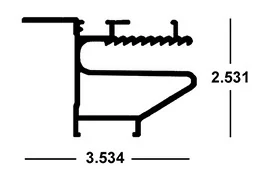

Sign Frame With Retainer Sign Frame Without Retainer

Sign Frame Without Retainer Bleed Retro Frame

Bleed Retro Frame Flex Retro Frame

Flex Retro Frame

Advantages of aluminium sign frame extrusions

- Aluminum is lightweight and strong, making it suitable for sign production.

- Aluminum is corrosion-resistant and durable, allowing for long-term use.

- Aluminium sign frame extrusions can be processed quickly, resulting in low manufacturing and transportation costs.

- Aluminium sign frame extrusions can be shaped into various forms and cross-sections to meet personalized needs.

- Aluminium sign frame extrusions have a stylish appearance, suitable for modern design aesthetics.

- Aluminum is compatible with various metals, supporting riveting, welding, and other forming processes.

- Aluminum is recyclable multiple times, making it environmentally friendly and sustainable.

Applications of aluminium sign frame extrusions

- Billboards and promotional signs

- Post and panel systems

- Trade show displays

- Wall-mounted signs

- Canvas sign frames

- Venue identification and directional signs

- Boxed sign systems

- Storefronts and signage

- Exterior wall plaques

- Bulletin boards and menu boards

- Display stands, poster sign holders

Surface treatment options for aluminium sign frame extrusions

Mill finish

Mill Finish refers to the original surface condition of the aluminum sign frame extrusions after extrusion, retaining the natural appearance of the metal.

Anodized surface treatment

This is an electrochemical process used to protect the surface of aluminum sign frame extrusions, forming a corrosion-resistant coating through oxidation.

Powder coating finish

A powder made from a mixture of resins and pigments is applied to the surface of the aluminum sign frame extrusions.

Powder coatings provide UV resistance and corrosion protection, with a variety of color options.

Electrophoretic coating

Using electrophoretic technology, the coating adheres evenly to the surface of the aluminum sign frame, enhancing both corrosion resistance and aesthetics.

Sandblasting surface treatment

Fine sand particles are projected at high speed to impact the aluminum surface, removing the oxide layer, dirt, and other impurities while creating a fine texture on the surface.

Chemical polishing surface

This is a chemical polishing method that involves immersing the extrusions in a strong oxidizing agent to achieve a super bright mirror finish.

Manufacturing process of aluminium sign frame extrusions

Cold extrusion

Process Overview: This extrusion method is performed at room temperature. As long as the mold is strong enough to withstand the stresses produced during extrusion, cold extrusion is an ideal choice for manufacturing aluminium sign frames.

- Cold-processed aluminium sign frame extrusions have high strength.

- They feature tighter tolerances and an excellent surface finish.

Hot extrusion

Process Overview: This extrusion occurs within 50-75% of the melting temperature of aluminium.

- It requires higher pressure and temperature.

- Good lubrication is essential.

- While the cost of hot extrusion is relatively high, it is suitable for producing complex shapes and large-sized aluminium profiles.

Hydrostatic extrusion

This method uses pressurized liquid to envelop the aluminium workpiece, reducing the required force and impact during extrusion.

It lowers the force requirements in the extrusion process, enhancing production efficiency.

Mastar's service features

Free samples and customization services

We offer free samples and customization services, supporting OEM/ODM needs to meet our clients' diverse requirements.

Processing services

Mastar provides processing services, including drilling, punching, countersinking, welding, bending, forming, precise cutting, and deburring.

Assembly services

We can assemble products according to your assembly instructions and deliver the assembled products directly to you.

Fast delivery and high-quality production

We are committed to providing quick delivery times while ensuring high-quality standards for our aluminium extrusion products.

How to install aluminium sign frame extrusions?

Aluminium sign frame extrusions come in two different designs: slide-in and bolt-on.

To install the slide-in frame, simply slide it in from the top. You may also need to secure the sign in place with bolts to ensure it stands upright.

For bolt-on aluminium sign frame extrusions, screw holes are located along the edges of the frame. Use bolts to firmly attach the sign to the frame, ensuring its stability.

Differences between aluminium sign frame extrusions and stainless steel sign frame extrusions

- Weight: Aluminium is lighter, making it suitable for lightweight applications.

- Complex Extrusion Profiles: Aluminium can be manufactured into complex profiles, allowing for flexible designs.

- Assembly and Transportation: Aluminium is easy to assemble and transport, reducing logistics costs.

- Cost: Aluminium has a lower production cost, making it ideal for mass production.

- Cleaning: Aluminium is easy to clean and maintain.