- Inspect the aluminum window and assess the problem

- Prepare the tools and materials needed for aluminum window repair

- Replacing the aluminum window screen

- Replacing damaged glass in aluminum windows

- Replacing the new aluminum window track

- Repairing scratches and dents on aluminum frames

- Repairing hardware components of aluminum alloy windows

- Routine inspection and maintenance of aluminum windows

- Common questions when repairing aluminum windows

Has your aluminum window encountered any problems? Whether it's the window frame, glass, mosquito net damage, lock malfunction, or seal damage, ignoring these issues can lead to safety risks. However, as long as you have the correct knowledge and tools, you can easily carry out repairs, saving time and money.

Here is the most comprehensive guide on repairing aluminum windows compiled by Mastar, where you can find solutions to the problems you are facing.

Inspect the aluminum window and assess the problem

Before attempting any repairs, thoroughly examine the root cause of the damage to the aluminum window. This helps ensure that you use the correct repair methods. Common issues with aluminum windows may include broken glass, torn window screens, damaged seals, scratches or dents in the frame, and hardware malfunctions such as handles or hinges.

Identifying these problems will help you determine the priority order for repairs and ensure that you have all the necessary tools and materials on hand.

Prepare the tools and materials needed for aluminum window repair

- Tape measure

- Screwdriver

- Pliers

- Putty knife

- Glass cutter

- Silicone sealant, epoxy resin

- Replacement hardware (such as handles or hinges)

- Level

- Caulking gun

- Spline roller

Remember to proceed with caution and prioritize safety during the repair process, as fixing damaged windows can involve certain risks.

Replacing the aluminum window screen

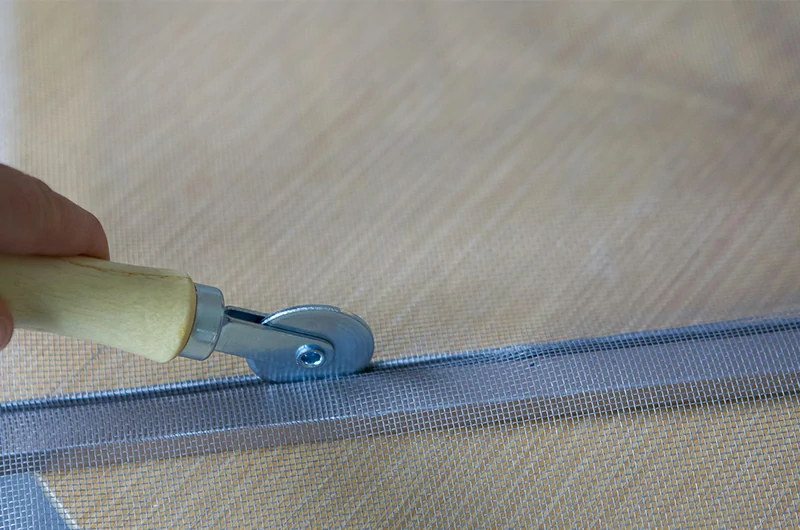

Note: Please prepare the spline roller tool (as shown in the picture below) in advance when replacing the window screen.

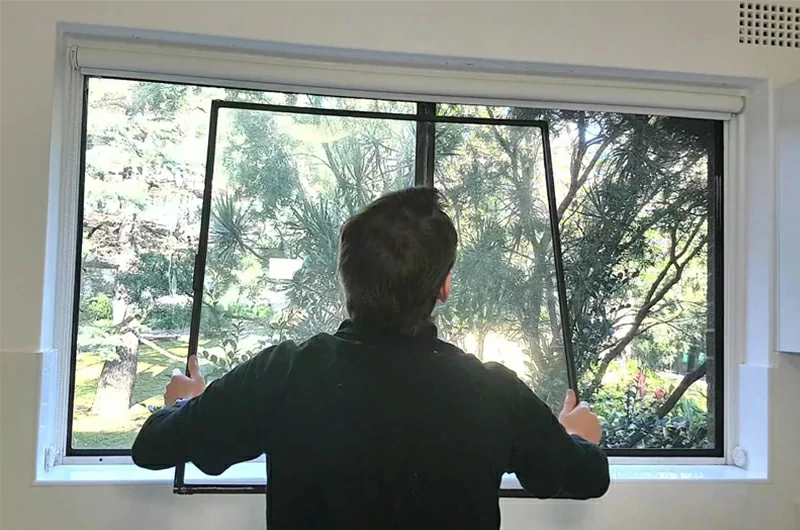

Step 1: Remove the screen window along with its frame from the door and lay it flat on a workbench.

Step 2: Use small pliers or a woodworking awl to pry the spline out of the groove. If the corners are too tight, use a screwdriver to remove the spline.

Step 3: Remove the old window screen.

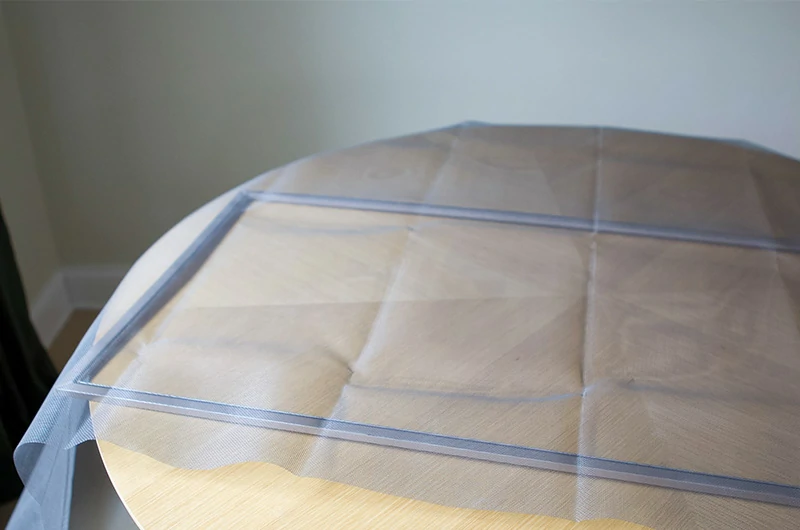

Step 4: Place the new window screen on the aluminum frame, ensuring that its edges overlap the groove by at least 1/8 inch. Trim off any excess screen outside the spline groove.

Step 5: Hold the spline roller at a 45-degree angle to the inner edge of the groove, then roll downward to press the window screen into the groove. This is the most challenging part! My suggestion is to start pressing from the top of the window screen downwards.

Step 6: Use the concave end of the spline roller to press the spline into the groove. Note that the concave end of the spline roller is used in the opposite direction to the spline roller used in the previous step (as shown in the picture below).

Final step: Place the blade tip between the spline and the outer edge of the spline groove, then slowly pull the blade along the entire groove to trim off the excess window screen.

Replacing damaged glass in aluminum windows

Disassembling damaged glass

Because broken glass is very sharp, please wear protective gloves before disassembling the glass.

If it's a fixed window, first look for screws hidden behind the plugs, which you can remove using a screwdriver. Unscrew all the screws until the window component loosens, and then you can pull it out from the frame.

If the window being replaced is a sliding window, lift it from the bottom until the bottom of the window frame can be moved off the track.

If the window to be replaced is a hinged window, unscrew the screws that secure the opening device to the window frame, and then remove the window frame.

Select the appropriate size glass

You must choose glass of the same shape and size to fit the aluminum window frame. It's important to choose the correct thickness depending on whether it's single or double strength glass. If you're unsure about the thickness, take a piece of old glass to the glass store for advice.

Installing the new glass

Place rubber gaskets around the edges of the replacement glass, running them along the outside of all edges. Then, insert the new glass into the frame, tighten all screws securing the glass, and reassemble the frame in the reverse order of disassembly.

If it's a sliding window, you'll need to apply sealant into the gap between the new glass and the frame to seal it. Finally, reinstall the entire aluminum window back onto the wall.

Replacing the new aluminum window track

Fill the caulking gun with sealant and apply a thin bead of silicone sealant along the entire bottom of the new track. Apply about an inch (25 millimeters) at each end to prevent it from squeezing out.

The trickiest part! Be careful with your track, do not bend it, and hook one end onto the old damaged track. Slowly lower the new track, gently pressing down until the entire length covers the old track.

Lift the window and gently raise it into place. Slowly move it back and forth along the new track.

Tip: There are small ventilation holes between the window sill and the bottom of the aluminum frame that you need to check. Make sure these holes can drain properly. If they are blocked, your window may accumulate water. Use an awl to open them if they are blocked.

Repairing scratches and dents on aluminum frames

Repairing surface scratches

For minor scratches, start by cleaning the area with a mild detergent and a soft cloth to remove dirt or debris.

Next, gently sand the scratched area with fine sandpaper. After sanding, wipe the area clean, and finally apply a layer of paint in the same color to protect it.

Repairing deeper scratches

Deeper scratches require a more thorough treatment. After cleaning, fill the scratch with putty or aluminum filler.

Ensure the filler is smooth and level with the frame surface. Once the filler has dried, sand the area until smooth, and finally apply a layer of paint in the same color.

Repairing small dents

For smaller dents, start by cleaning the area. Then, use a specialized dent puller tool to try and pull out the dent. If successful, sand any minor unevenness with fine sandpaper and apply paint as needed.

Repairing larger dents

Larger dents may require the use of a heat source (such as a heat gun) to make the aluminum frame more malleable. After heating, gently push the dent out from the other side.

Once the dent is repaired, fill any remaining irregularities with aluminum filler, sand the area smooth, and then apply a layer of paint.

Repairing hardware components of aluminum alloy windows

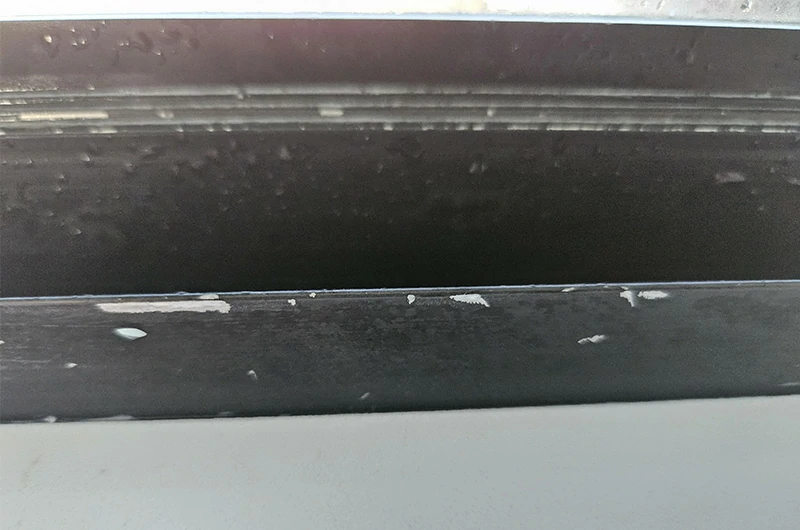

Cleaning the tracks

The tracks of sliding windows can accumulate debris and dirt over time, leading to difficulty in opening and closing. This can be dangerous! As you may need to apply more force to open the window, which can damage the handles, locks, or even cause the window to come completely off the track.

To prevent this situation, it's necessary to clean the tracks regularly.

Replacing handles and locks

In most cases, replacing handles and locks on windows is relatively simple and inexpensive. You just need to purchase the new parts and replace them using a screwdriver.

Replacing rollers

The most common issue with aluminum sliding windows is related to the rollers, most of which are secured with screws or clips. Use a screwdriver or pliers to remove the screws or clips, then pull the roller assembly out from the bottom.

Repairing spring balances

Damaged spring balances can be very dangerous, as windows may accidentally trap fingers or get stuck in an open or closed position. If there is an issue, it's best to contact a professional immediately.

Routine inspection and maintenance of aluminum windows

Develop a habit of checking the aluminum frame, seals, and hardware for cracks, leaks, or damage. Clean the tracks and lubricate all moving parts to ensure smooth operation. By addressing any minor issues promptly, you can avoid more extensive repairs in the future.

Another key aspect of maintaining aluminum windows is to protect them from environmental factors. This includes regularly cleaning the aluminum frames and glass, ensuring drainage holes are clear to prevent water accumulation, and applying a protective coating if necessary to prevent corrosion.

Common questions when repairing aluminum windows

Q: Can I repair my aluminum windows myself?

A: Yes, homeowners can perform basic repairs on aluminum windows as long as they have the correct tools and knowledge.

Q: How do I repair a drafty aluminum window?

A: To fix a drafty aluminum window, you can replace the weatherstripping, seal all gaps with silicone caulk, or adjust the window's hinges or locking mechanisms.

Q: How often should aluminum windows be inspected for repairs?

A: It is recommended to inspect aluminum windows for repairs at least once a year, and more frequently in areas with extreme weather.

Q: Why repair aluminum windows instead of replacing them?

A: In some cases, repairing aluminum windows is more cost-effective than replacing them.

Q: How much does it cost to repair aluminum windows?

A: The cost depends on the cause of the damage to your aluminum window and the local price levels.