Mirror frame aluminum profile is an aluminum extrusion profile specially used for making mirror and glass frames, usually used to fix, protect and decorate the mirror surface. Its structure is usually optimized to adapt to the edge processing requirements of the mirror frame while providing beauty and durability.

Mastar can supply various types of aluminum profiles for frames with rich sizes and low minimum order quantity. It also supports various surface treatments and cutting customization services to meet the personalized needs of customers.

Introduction to Mastar's mirror frame aluminum profiles

| Alloy | 6063, 6061, 6463 |

| Temper | T5, T6 |

| Specification | ASTM B221, BS EN 755 |

| Thickness | 0.5mm – 3mm or customize |

| Length | 3.0m-6m or customize |

| Type | Single-sided display, double-sided display; floor-standing type, wall-mounted type |

| Deep processing | CNC, drilling, milling, cutting, stamping, welding, bending, assembly |

Mastar's popular mirror frame aluminum profiles

L-shaped aluminum profiles for mirror frames

- L-shaped aluminum profiles are often used for edge protection or corner support of mirror frames. Its 90-degree angle design makes it ideal for supporting and fixing mirrors or glass panels, especially in applications that require a strong edge.

- Alloy: 6063, 6061

- Common sizes: width 10-20mm, height 10-30mm, thickness 1-2mm

- Advantages: simple structure, easy to install, can form a natural edge in the frame, play a decorative and protective role

- Application: bathroom mirror frames and small wall mirrors.

J-shaped aluminum profile for mirror frame

- J-shaped aluminum profile is mostly used for hanging devices of mirrors or glass. Its open curved design makes it easy to slide the mirror in, which is convenient for installing or removing the mirror.

- Alloy: 6063, 6061

- Common sizes: width 10-15mm, height 15-25mm, thickness 1-2mm

- Advantages: J-shaped opening is easy to install and remove, suitable for mirror installation that requires flexible replacement or maintenance, and provides certain edge protection

- Application: wall-mounted mirror frame or bathroom mirror.

H-shaped aluminum profiles for mirror frames

- H-shaped aluminum profiles are mainly used to connect two or more mirror panels, and are commonly seen in spliced large mirror walls or combined mirror frames. The H-shaped middle partition design helps to accurately align the mirror surface and maintain flatness.

- Alloy: 6063, 6061

- Common sizes: width 15-30mm, height 20-40mm, thickness 1.5-2.5mm

- Advantages: H-shaped design increases load-bearing capacity and alignment, suitable for splicing frame structures that require stable support, and can maintain overall flatness

- Application: Suitable for splicing large mirror walls, gym frames or display walls.

F-shaped aluminum profile for mirror frame

- F-shaped aluminum profile is suitable for scenes where multiple panels or layers need to be fixed, such as mirror frame structures with multiple protective layers, due to its multiple notch design.

- Alloy: 6063, 6005

- Common sizes: width 20-40mm, height 25-50mm, thickness 2-3mm

- Advantages: Multiple slot structure, capable of carrying multiple layers or complex structures, suitable for high-end mirror frames that require multiple layers of support and complex decoration

- Application: Suitable for high-end decorative mirror frames, display frames and mirror structures with multiple layers of protection, often used in art exhibitions and luxury decorative mirrors

Victorian Mirror Frame Extrusion

- Victorian style mirror frame aluminum profile is a kind of aluminum frame with retro decorative style. It is usually treated with special surface treatment, such as antique electroplating, brushed or distressed effect. Common colors include gold, bronze, black and silver.

- Alloy: 6063, 6061

- Common size: width 20-60mm, thickness 2-4mm, length 3m

- Advantages: With exquisite retro relief and diverse surface treatment, it presents an elegant and luxurious appearance

- Application: Widely used in homes, commercial spaces and high-end custom occasions, adding elegant decorative effects of retro style

Bull nose mirror frame extrusion

- The bullnose frame gives the mirror a rounded appearance, with the bullnose edge perfectly matching the countertop. It can undergo surface treatments like anodizing or spraying, offering various colors and textures to suit diverse decor styles.

- Alloy: 6063, 6061

- Advantages: Unique curved design, rounded appearance, can provide better vision and aesthetic effect.

- Application: Modern or industrial style home mirror frames, decorative mirrors in beauty salons, fashion stores and other places.

Common surface treatments for Mastar's aluminum mirror frames

Mastar aluminum frames usually support a variety of surface treatment services, making your frames look beautiful and durable. Below are the most popular surface treatments for aluminum profiles.

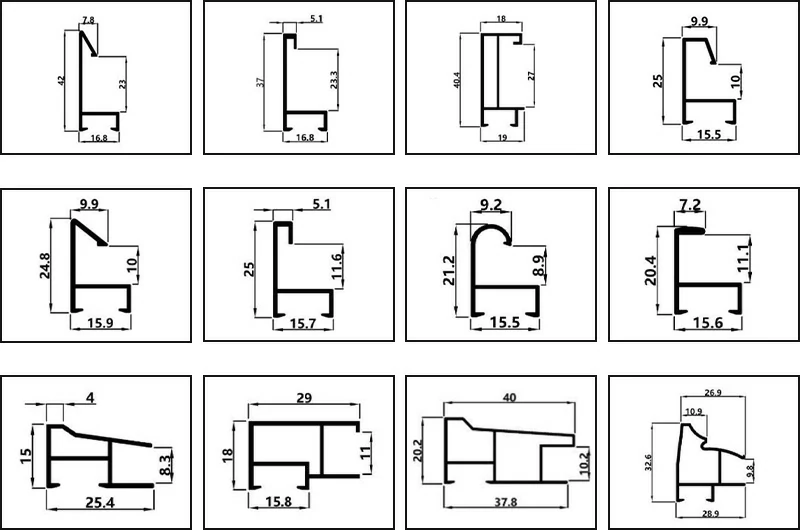

Partly mirror frame drawings

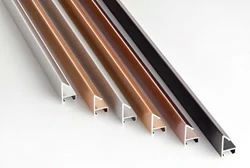

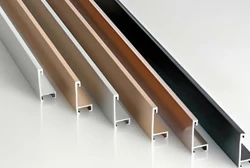

Mastar's aluminum mirror product display

Why use aluminum profiles for mirror frames?

Durable: Aluminum profiles have good strength and corrosion resistance, can maintain their appearance for a long time, and are not easy to be damaged or rusted.

Beautiful: Through surface treatment, multiple colors can be produced to meet different design styles and enhance the decorative effect.

Cheap: Aluminum profiles are cost-effective and suitable for large-scale production, reducing overall costs.

Corrosion resistance: Applicable to various scenarios, and not afraid of humid environments.

Easy to install: The design usually takes into account easy installation and fixing, and can adapt to a variety of installation methods.

Easy to process: Different shapes can be produced through extrusion, bending and other processes to meet the different needs of customers.

What should customers pay attention to when choosing aluminum profiles for mirror frames?

- Alloy type: Confirm the required aluminum alloy type to ensure that the strength and corrosion resistance requirements are met.

- Dimensions: Clarify the size of the frame, including width, thickness and length, to ensure that it matches the mirror surface.

- Design style: Choose a frame design that matches the overall decoration style, considering the aesthetics of the shape and pattern.

- Surface treatment: Pay attention to surface treatment options such as anodizing, spraying or electrophoresis to ensure its durability and appearance.

- Installation method: Consider the installation method of the frame and ensure that the selected profile is suitable for the required installation method.

- Environmental adaptability: Choose the appropriate aluminum profile according to the use environment (such as indoors, outdoors or wet areas) to increase its durability.

- Budget constraints: Clarify the budget range and choose cost-effective aluminum profiles to meet the needs without overspending.

- Supplier reputation: Choose a reputable supplier to ensure material quality, service and after-sales support.

Mastar ensures delivery of high quality frame aluminum profiles

- In order to ensure high quality products for customers, Mastar usually provides the following testing services:

- Alloy detection: Aluminum profile alloy detection evaluates its chemical composition to ensure compliance with standards through methods such as spectral analysis, chemical analysis and X-ray fluorescence, thereby ensuring material performance and quality.

- Surface detection: Evaluate the surface quality of aluminum profiles, including scratches, pits, uneven oxide film and other defects.

- Coating thickness detection: Measure the thickness of the coating on the surface of the aluminum profile to ensure that it meets the design requirements.

- Flatness detection: Check the flatness of the aluminum profile to ensure that it does not warp or deform during use.

- Weight measurement: Use an accurate electronic balance to weigh, calculate the theoretical weight based on the size and density of the aluminum profile, and compare it with the actual weight to ensure that it is within the allowable error range. The accuracy of weight is crucial for the safety of transportation and use.