Large-section profiles refer to aluminum profiles with a cross-sectional width of over 300 mm. They offer enhanced mechanical performance and stability, specifically designed for applications requiring heavy loads and high strength. These profiles are mainly used in aerospace, transportation, wind power, and nuclear energy sectors.

Mastar, as a renowned aluminum supplier, is dedicated to providing high-quality large-section aluminum profiles. We can customize various complex cross-sectional shapes and extrude profiles up to 750 mm in width, offering precise and professional solutions for large-scale projects.

Large-section aluminum profiles in the aerospace industry

Wing rib aluminum profiles

Wing rib aluminum profiles- Wing rib aluminum profiles are lightweight, high-strength aluminum alloy profiles used in aircraft wing rib structures, primarily to support and maintain the shape and stability of the wings.

- Common alloy: 2024

Wing frame profiles

Wing frame profiles- Wing frame aluminum profiles are high-strength aluminum alloy profiles specifically designed to support the internal structure of aircraft wings. They offer lightweight, high strength, and excellent fatigue resistance, ensuring wing stability and overall structural reliability during flight.

- Common alloy: 2024, 7075

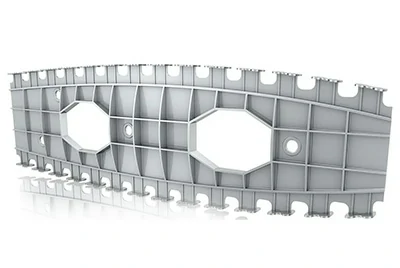

Airplane body frame aluminum profiles

Airplane body frame aluminum profiles- Airplane body frame aluminum profiles are high-strength, lightweight aluminum alloy profiles used to construct the aircraft fuselage structure, providing the necessary support and stability to withstand stresses during flight.

- Common alloy: 2024, 7050

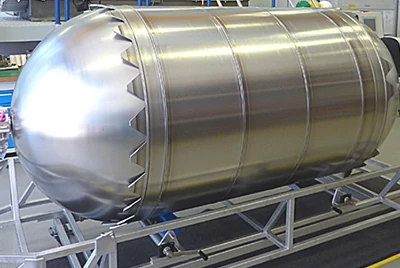

Rocket propellant tanks

Rocket propellant tanks- Aluminum rocket propellant tanks are containers made from aluminum alloys, used to safely store and supply the liquid fuel and oxidizers required for rocket engines. Due to their lightweight and high-strength characteristics, they are widely used in rocket design.

- Common alloy: 2219

Large-section aluminum profiles for transportation

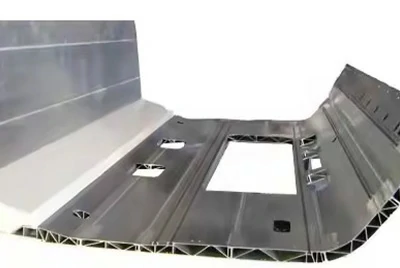

Subway roof extruded aluminum profiles

Subway roof extruded aluminum profiles- Subway roof aluminum profiles offer lightweight, high-strength, and corrosion-resistant properties, providing the structural strength and stability required for the vehicle body.

- Common alloy: 6061, 6063

Subway body aluminum extrusions

Subway body aluminum extrusions- Mastar's subway body aluminum profiles, made from 6063 or 6082 aluminum alloys, offer the necessary strength and performance while reducing the overall weight of the train. The surface can be treated with milling, anodizing, or powder coating to fully meet decorative requirements.

Aluminum profiles for trailers

Aluminum profiles for trailers- Mastar offers custom aluminum extruded flooring for trailers and truck trailers, using materials such as 6082-T6, 6061-T6, 6063-T6, and 6005A-T6 aluminum alloys. We also produce custom interlocking aluminum decking and provide CNC machining and decking assembly services.

Aluminum profiles for container floors

Aluminum profiles for container floors- Mastar supplies high-strength and corrosion-resistant aluminum profiles for container floors, with widths up to 750mm, fully meeting container manufacturing

- Common alloy: 6061, 6082

Aluminum profiles in wind power generation

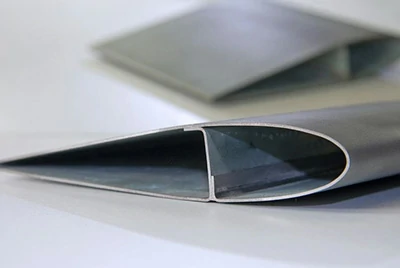

Aluminum profiles for wind turbine blades

Aluminum profiles for wind turbine blades- Blades with a constant chord length, made from extruded aluminum alloy, are easy to manufacture and can be produced continuously. They can also be twisted according to design requirements. Typically, 7075 aluminum alloy is used.

Fan tower support structure

Fan tower support structure- The fan tower support structure aluminum profiles are used to support the structural components inside the wind turbine tower, ensuring its stability and load-bearing capacity. These aluminum profiles are typically made of 6061-T6 or 6082-T6 alloys, which are known for their excellent mechanical strength, corrosion resistance, and good machinability, to meet the high-performance requirements needed for towers in wind power systems.

Fan base frame

Fan base frame- The fan base frame commonly uses 6005A-T6 and 6082-T6 aluminum alloys to provide the necessary strength to support the entire fan structure.

Blade root connection structure

Blade root connection structure- The blade root connection structure requires higher strength and fatigue resistance. 2024-T3 and 7050-T7451 alloys provide extremely high strength and fatigue resistance, making them ideal materials for connecting the blades to the main shaft.

Large aluminum profiles in the construction field

Main girders

Main girders- As the primary load-bearing structure of a bridge, main girders made from 6061-T6 or 6082-T6 alloys provide the necessary strength and rigidity while reducing the overall weight.

Bridge deck panels

Bridge deck panels- Bridge deck panels are aluminum profiles used for the surface of bridges for vehicle and pedestrian traffic. Commonly used alloys include 6061-T6 and 6082-T6, which provide excellent strength and corrosion resistance.

Structural supports

Structural supports- Columns and beams serve as the main support structures in buildings. Using large-section aluminum profiles can achieve high strength and lightweight properties, making them especially suitable for large commercial and industrial buildings.

Large-section motor housing aluminum profiles

Large diameter water-cooled electric motor housing

Large diameter water-cooled electric motor housing- Extruded water-cooled motor housings have a compact structure, featuring internal spiral water channels and a special argon arc welding process that improves sealing at the waterway connections. The internal spiral channels are divided into an inlet and an outlet, allowing water flow to dissipate heat generated during high-speed motor operation.

- Recommended alloys: 6063 and 6061

Large heat exchangers

Large heatsinks

Large heatsinks- Mastar's extruded heat exchangers feature a high aspect ratio, reaching 15-20, which significantly enhances the thermal performance required for high-power electronics.

- Commonly used alloy: 6063

Advantages of large-section aluminum profiles

Higher load-bearing capacity: Large-section aluminum profiles can handle greater loads and stresses, making them suitable for high-strength applications.

Better structural stability: Large-section aluminum profiles provide greater rigidity and stability, reducing deformation and wobbling.

Enhanced design flexibility: Large-section aluminum profiles support complex structural designs, meeting diverse engineering needs.

Improved mechanical performance: Larger cross-sections offer superior resistance to bending and shear forces.

Greater durability: Due to their thicker sections and high strength, large-section aluminum profiles typically have a longer service life.

Superior deformation resistance: Larger cross-sections effectively distribute stress, minimizing deformation.

The development prospects of large aluminum profiles

Market demand growth: The demand for large aluminum profiles in construction, transportation, and industry is expected to significantly increase, surpassing the market space of standard aluminum profiles.

Technological innovation: Future technological advancements will further enhance the performance of large aluminum profiles, such as increasing strength and processing precision, exceeding the capabilities of standard profiles.

Diverse application expansion: As new fields develop, large aluminum profiles will be applied in more high-demand applications, extending beyond the usage range of standard profiles.

Structural design optimization: Large aluminum profiles will continue to drive the application of complex structures and high-performance designs, meeting future engineering needs and surpassing the design capabilities of standard profiles.

What services can Mastar provide you with?

Customized production: Designing and producing large-section aluminum profiles in various shapes and specifications based on customer requirements.

Multiple alloy options: Offering various aluminum alloys, such as 6061 and 6063, to meet different application needs.

Advanced production technology: Utilizing automated extrusion and processing equipment for high precision and quality surface finishes.

Surface treatment: Providing anodizing, electrophoretic coating, and other treatments to enhance corrosion resistance and appearance.

Technical support: Offering design consultation and after-sales services to ensure customer needs are met.