What is an air conditioning pipe system?

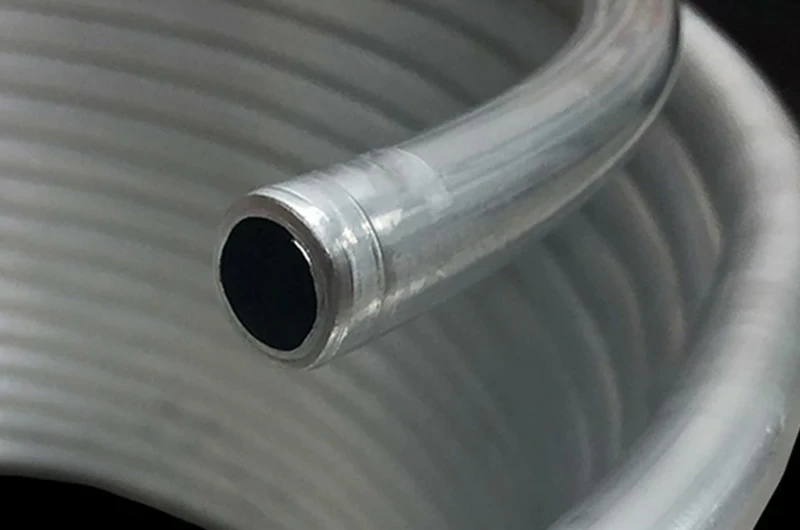

The air conditioning pipe system is an essential component of air conditioning equipment, responsible for circulating refrigerants (such as freon) between various components of the air conditioner to achieve cooling and heating functions.

The working principle of air conditioning

- The evaporator coil of the air conditioner absorbs heat from indoor air.

- Cool refrigerant flows through these coils, carrying away heat.

- This refrigerant flows to the compressor where it is compressed into a hot liquid.

- The hot liquid then passes through condenser coils, releasing heat and becoming cool.

- The cooled refrigerant returns to its original state through an expansion valve, ready to flow back to the evaporator coil again.

This process repeats continuously until the indoor temperature reaches the temperature you have set.

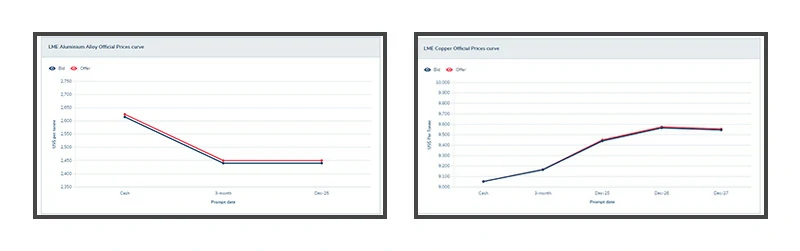

In most air conditioning systems, aluminum or copper pipes are commonly used. Each type has its own pros and cons, making the choice between them sometimes challenging. Therefore, we've outlined key points to help clear up any confusion.

Corrosion resistance

Copper pipes: Copper exhibits excellent corrosion resistance. When exposed to air during the cooling process, oxidation occurs. Copper effectively resists oxidation and corrosion, thereby extending the lifespan of air conditioning equipment and ensuring long-term stable operation.

Aluminum pipes: Aluminum is less corrosion-resistant compared to copper. Over time, it tends to form an oxide layer, which can make its surface more vulnerable. To enhance its corrosion resistance, additional coating or treatment is typically required.

Thermal conductivity

Copper pipes: Copper has excellent thermal conductivity with a value of approximately 398 W/mK, allowing it to quickly transfer heat and enhance cooling efficiency, resulting in better refrigeration effects.

Aluminum pipes: Aluminum has a thermal conductivity of about 235 W/mK, which is sufficient but considerably lower than copper. Therefore, its cooling efficiency is slightly inferior compared to copper.

Durability

Copper pipes: Copper has higher strength, capable of withstanding minor impacts without easily being damaged. If damaged, it can be relatively easily repaired using welding methods.

Aluminum pipes: Aluminum is softer compared to copper, prone to dents and deformation. Repairing aluminum is more challenging when damaged, often requiring complete replacement rather than repair.

Costs

Copper pipes: Copper is more expensive, leading to higher costs for installing large air conditioning systems.

Aluminum pipes: Aluminum is cheaper initially, making it suitable for budget-sensitive projects. However, in the long run, it may require more maintenance and replacement, increasing overall costs.

Installation and maintenance

Copper pipes: Copper is renowned for its durability but is inherently heavier, requiring more effort during installation. Installers often have to manage this additional weight, especially in confined spaces or when retrofitting existing systems.

Aluminum pipes: In contrast, aluminum pipes are lighter and easier to handle, speeding up the installation process, which is particularly beneficial when minimizing structural load is crucial.

Recyclability

Copper pipes: Copper has a very high recycling rate because it is easy to recycle and offers high cost-effectiveness in regeneration, saving approximately 90-95% of the energy needed to produce new copper.

Aluminum pipes: Similarly, aluminum has excellent recyclability, being easy to recycle without any loss of quality during the recycling process. It saves approximately 90-95% of the energy required for producing new aluminum.

Air conditioning pipe material: choosing between copper and aluminum

Air conditioner copper pipe selection advice

Application: Suitable for environments requiring high efficiency cooling, durability, and long-term usage, such as commercial air conditioning and large-scale building HVAC systems.

Reasons: Copper pipes exhibit excellent thermal conductivity and corrosion resistance, enhancing air conditioner cooling efficiency and lifespan. Despite higher initial costs, they offer lower long-term maintenance and replacement expenses.

Air conditioner aluminum pipe selection advice

Application: Suitable for environments with limited budget or requiring lightweight installation, as well as humid and high-salt areas such as household air conditioners, small office HVAC systems, and air conditioning for seaside resorts.

Reasons: Aluminum pipes are lightweight, easy to install, and resistant to salt corrosion. They have lower initial costs and are suitable for cost-sensitive projects. However, they are more fragile, requiring higher maintenance and replacement frequency.

What services can Mastar assist you with?

- Mastar can provide high-quality copper and aluminum pipes to meet your different needs. Whether it's copper or aluminum pipes, Mastar can offer reliable solutions. If you're uncertain about your choice, please contact us.

- Mastar can provide professional and detailed quoting services to ensure competitive prices for your air conditioner copper or aluminum pipes.

- With a large inventory, Mastar can meet your urgent orders without delaying your production.

- Once you connect with Mastar, we will promptly update product prices to ensure you get the latest prices.