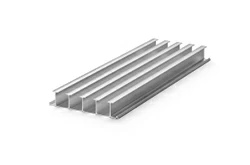

Master Company specializes in the research and production of high-quality aluminum profiles, offering a variety of alloys and specifications for aluminum sheets. Mastar aluminum sheet and profiles are widely used in container side panels and floors, our products boast excellent corrosion resistance, high strength, and durability.

Perfect Application of Mastar Aluminum Profiles in Containers

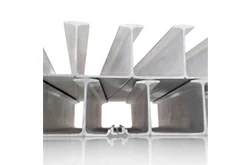

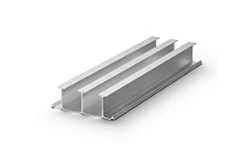

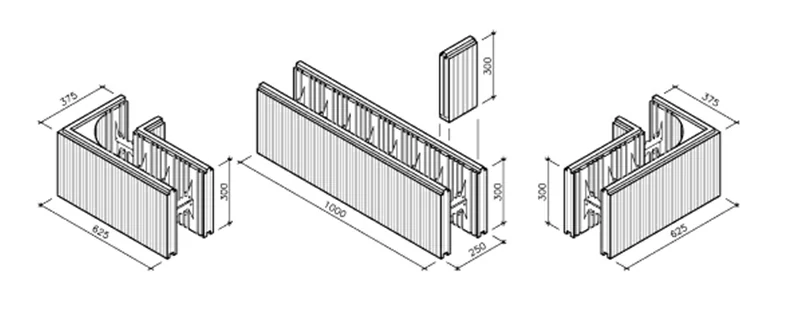

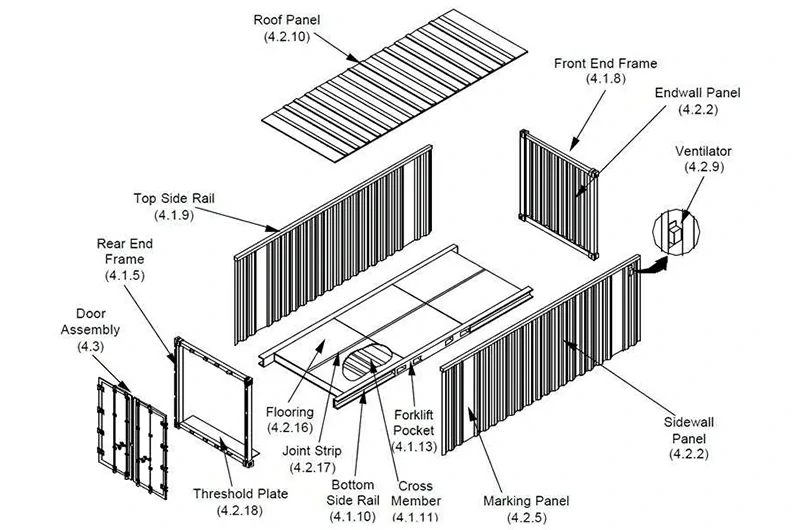

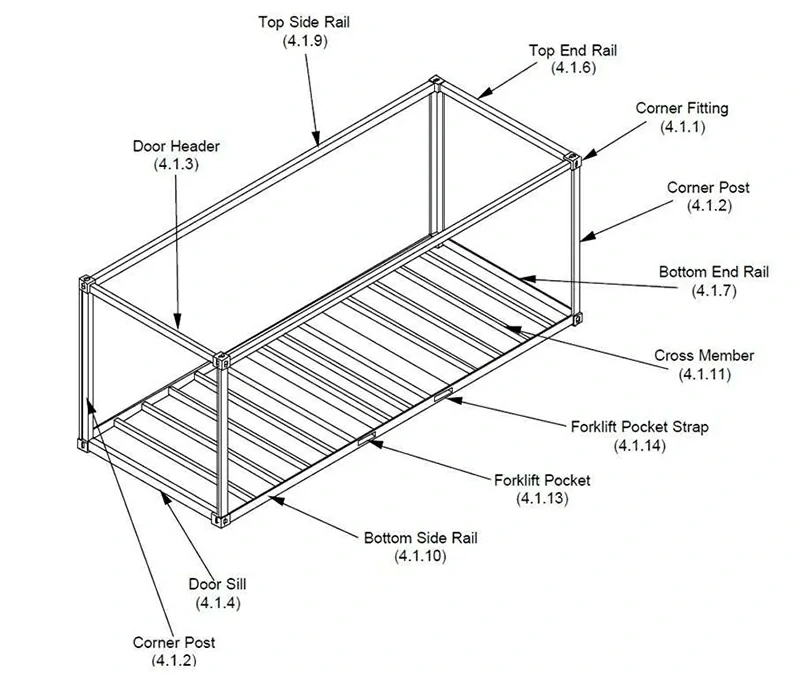

- Structural Components: Aluminum profiles are the backbone of containers, used for frameworks, corner posts, and floor supports. These custom aluminum extrusions ensure the container remains rock-solid, impervious to wind and rain.

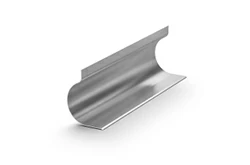

- Wall Panels and Roof Panels: Sidewalls, end walls, and roof panels made from aluminum profiles act as sturdy armor for containers, protecting goods from external damage.

- Doors and Door Frames: Doors and door frames crafted from aluminum profiles offer excellent sealing, ensuring that the interior and exterior environments of the container remain separate, keeping goods secure.

- Insulation Layers: In refrigerated containers, aluminum profiles serve as superior insulation layers, maintaining a constant temperature and ensuring that temperature-sensitive goods like food and pharmaceuticals stay fresh.

Mastar enhances your business efficiency

Ideal choice for cold chain logistics

Needs: Safety and reliability in temperature-controlled transportation.

Mastar Solutions:

- Insulation Performance: Mastar's aluminum profiles, using 6082 aluminum alloy, maintain temperature fluctuations within ±2°C for up to 72 hours in a -20°C environment.

- Corrosion Resistance: With significantly better corrosion resistance than traditional steel, anodized aluminum profiles withstand salt spray environments for 1500 hours without noticeable corrosion.

- Case Study: Americold, after adopting Mastar's aluminum profile refrigerated containers, saw a 20% reduction in cargo loss and a 15% increase in customer satisfaction.

Strong support for manufacturing

Needs: Efficient and safe transportation of raw materials and finished products.

Mastar Solutions:

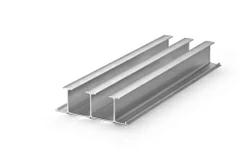

- High Strength and Lightweight: Mastar's 6061 aluminum alloy profiles are 30% lighter than similar steel containers but equally strong, significantly improving transportation load efficiency.

- Application Example: A large automobile manufacturer using Mastar's aluminum profile containers can load 10% more parts per shipment, reducing transportation costs by 15%.

Trusted choice for trade companies and exporters

Needs: Ensure the safety and integrity of goods during transport.

Mastar Solutions:

- Protection Performance: Mastar aluminum profile containers offer excellent shock, water, and theft resistance. In simulated transport vibration tests, the intact rate of internal goods reached 98%.

- Global Applicability: Mastar's aluminum profile containers meet ISO 1496-1 international standards, suitable for various transportation methods worldwide.

- Success Story: Tata International, after using Mastar's aluminum profile containers, reduced cargo loss by 25% and improved transport efficiency by 10%.

Logistics efficiency booster

Needs: Increase transportation efficiency and reduce costs.

Mastar Solutions:

- Lightweight Design: Mastar's 6063 aluminum alloy profile containers are about 25% lighter than traditional steel containers, significantly improving transport efficiency.

- Fuel Efficiency: The lightweight aluminum profile containers effectively reduce fuel consumption. According to FedEx, using Mastar's aluminum profile containers improved transport fuel efficiency by 6%.

Best choice for container manufacturers

Needs: Improve production efficiency and quality of containers.

Mastar Solutions:

- Processing Performance and Customizability: Mastar's aluminum profiles offer excellent processing performance, suitable for various complex custom shapes. For example, CIMC improved production efficiency by 20% and product qualification rate to 98% using Mastar's aluminum profiles.

- Cooperation Case: Triton International, using Mastar's aluminum profiles, increased the market share of high-end dry cargo containers by 15% and attracted multiple international logistics companies.

Mastar's aluminum profile solutions provide customized designs based on the needs of different customer groups, ensuring that each container type can meet specific application requirements.

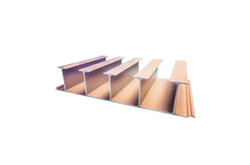

Product detail of Mastar Aluminum Profiles

- 6061 6063... for aluminum container...

- Surface options: anodizing, powder coating.

- Custom designs for different containers

Advantages of Mastar Aluminum Profiles

- Lightweight: Reduces the container's weight, enhancing transport efficiency and lowering costs.

- High Strength: Excellent strength and toughness ensure the container's structural safety.

- Corrosion Resistance: Superior corrosion resistance suits maritime transport and harsh climates, extending the container's lifespan.

- Eco-Friendly: Recyclable, reducing environmental impact and meeting sustainable development requirements.

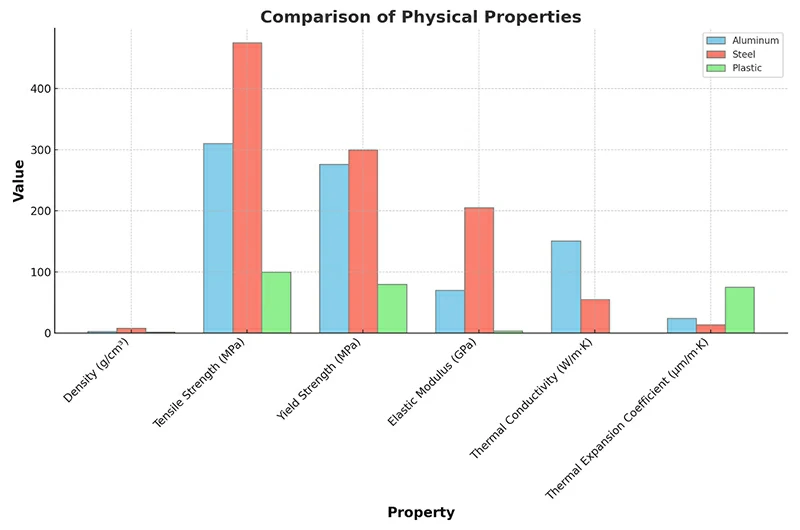

Mastar Aluminum Profiles vs. Other Materials

| Property | Aluminum Profiles | Steel | Plastic (Engineering Plastics) |

| Corrosion Resistance | Excellent (especially in marine environments) | Requires corrosion protection (e.g., galvanizing) | General, some materials resist chemical corrosion |

| Recyclability | High, infinitely recyclable | High, renewable | General, some plastics recyclable |

| Surface Treatment | Anodizing, electrophoresis coating | Galvanizing, coating | Usually none, but can be coated |

| Raw Material Cost | High | Low | Depends on type, usually low |

| Processing Cost | Medium, extrusion and surface treatment | Low, welding and galvanizing | Low, molding |

| Maintenance Cost | Low, excellent corrosion resistance | High, requires regular corrosion maintenance | Low, good chemical and corrosion resistance |

| Environmental Impact | Low, recyclable, environmentally friendly production | Medium, production and recycling pollution | High, some plastics hard to degrade, severe pollution |

| Container Types | Refrigerated, standard dry cargo | Standard dry cargo, specialized containers | Parts (e.g., locks, seals) |

| Pros | Lightweight, high strength, corrosion-resistant, recyclable | High strength, durable, relatively low cost | Lightweight, high plasticity, chemically corrosion-resistant |

| Cons | High cost, complex welding | Heavy, corrosive, maintenance required | Low strength, affected by temperature and UV |

Conclusion

Whether you are a cold chain logistics company, manufacturing enterprise, international trade company, logistics transport company, or container manufacturer, Mastar's aluminum profiles can meet your needs. Contact us to learn more about our products and custom services. Schedule a consultation or request a sample to experience the significant advantages and efficient solutions offered by Mastar's aluminum profiles.

Mastar looks forward to working with you to enhance business efficiency and competitiveness. Quick Quote