Aluminum alloys are becoming increasingly popular across various industries due to their versatility, strength, and lightweight characteristics. Understanding the different types of aluminum alloys and their properties can help you choose the best material for specific applications.

Aluminum alloys are typically divided into eight different series, ranging from 1xxx to 8xxx, with each series containing various grades. Below, we will provide a detailed explanation of the performance characteristics of aluminum alloys within each series and grade.

The performance of 1000 series aluminum alloys

The 1000 series aluminum alloys are over 99% pure aluminum with small amounts of other elements. 1060 and 1070 are noted for their excellent conductivity, while the 1100 series, known as commercial pure aluminum, is the softest among common alloys.

1050 pure aluminum

TemperTensile Strength (MPa)Yield Strength (MPa)Hardness (HB)Elongation (%)Conductivity (%IACS)Corrosion ResistanceWelding PerformanceSurface Treatment Difficulty

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (%IACS) | Corrosion Resistance | Welding Performance | Surface Treatment Difficulty |

| O | 76 | 25 | 21 | 39% | 61.3% | Excellent | Excellent | Good |

| H14 | 110 | 94 | 30 | 10% | 61% | Good | Good | Good |

| H24 | 110 | 84 | 34 | 8.4% | 61% | Good | Good | Good |

Applications: transformer belts, heat exchangers, signs, decorations, and cans.

1060 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 55-95 | ≤35 | 20-25 | 30-40 | 62 | Excellent | Excellent | Good |

| H12 | 70-110 | ≥40 | 25-30 | 15-20 | 62 | Excellent | Excellent | Good |

| H14 | 85-120 | ≥50 | 30-35 | 10-15 | 62 | Excellent | Excellent | Good |

| H18 | 105-135 | ≥80 | 35-40 | 3-5 | 62 | Excellent | Excellent | Good |

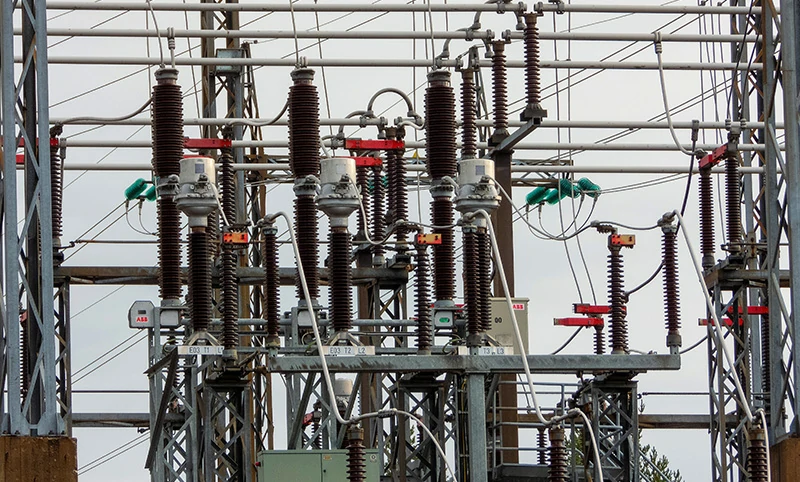

Applications: electrical wires, cables, busbars, heat sinks, and transformer windings.

1070 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 60-100 | ≤35 | 19-25 | 30-40 | 62.7 | Excellent | Excellent | Good |

| H12 | 80-110 | ≥40 | 25-30 | 20-25 | 62.7 | Excellent | Excellent | Good |

| H14 | 90-125 | ≥50 | 30-35 | 15-20 | 62.7 | Excellent | Excellent | Good |

| H18 | 110-145 | ≥80 | 35-40 | 5-8 | 62.7 | Excellent | Excellent | Good |

Applications: electrical conductors, busbars, and transformer windings.

1100 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 70-120 | 30-50 | 22-28 | 30-45 | 59 | Excellent | Excellent | Excellent |

| H12 | 85-125 | 45-70 | 30-35 | 20-25 | 57 | Excellent | Excellent | Excellent |

| H14 | 95-135 | 55-80 | 35-40 | 15-20 | 55 | Excellent | Excellent | Excellent |

| H18 | 120-160 | 85-105 | 40-45 | 5-10 | 55 | Excellent | Excellent | Excellen |

Applications: heat exchanger fins, spun hollow containers, cookware, and rivets.

1350 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 60-105 | 20-45 | 19-23 | 20-30 | 61.8 | Excellent | Excellent | Good |

| H12 | 85-120 | 30-55 | 25-30 | 15-20 | 61 | Excellent | Excellent | Good |

| H14 | 95-130 | 40-70 | 28-32 | 10-15 | 61 | Excellent | Excellent | Good |

| H18 | 115-145 | 55-90 | 32-38 | 5-10 | 61 | Excellent | Excellent | Good |

| H19 | 120-155 | 60-95 | 35-40 | 3-8 | 61 | Excellent | Excellent | Good |

Applications: electrical conductors, aluminum wires, and transformer windings.

2000 series aluminum alloys

The 2000 series primarily contains copper, offering high strength and heat resistance. It's used in military, aerospace, and high-performance applications.

2011 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T3 | 380-430 | 290-340 | 100-110 | 10-15 | 36 | Fair | Poor | Fair |

| T4 | 370-420 | 275-325 | 95-105 | 12-16 | 39 | Fair | Poor | Fair |

| T6 | 440-490 | 370-420 | 110-120 | 8-12 | 39 | Fair | Poor | Fair |

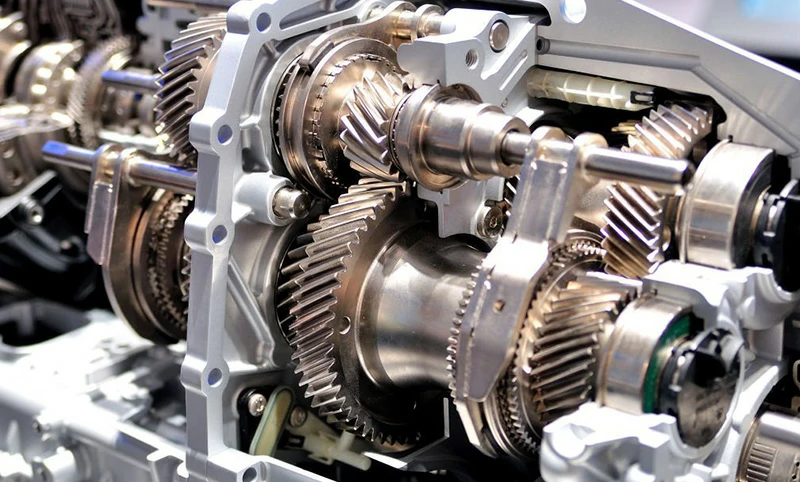

Applications: screw machine parts, small precision gears, and components for clocks, cameras, and speedometers.

2014 aluminum alloy

TemperTensile Strength (MPa)Yield Strength (MPa)Hardness (HB)Elongation (%)Conductivity (% IACS)Corrosion ResistanceWeldabilitySurface Treatment

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 190-270 | 95-140 | 60-75 | 18-22 | 50 | Fair | Good | Good |

| T3 | 415-465 | 275-325 | 110-120 | 10-15 | 32.5 | Poor | Fair | Fair |

| T4 | 410-460 | 270-320 | 105-115 | 12-16 | 34 | Poor | Fair | Fair |

| T6 | 460-510 | 400-450 | 120-135 | 8-12 | 38 | Poor | Poor | Fair |

| T651 | 455-505 | 395-445 | 120-135 | 9-13 | 40 | Poor | Poor | Fair |

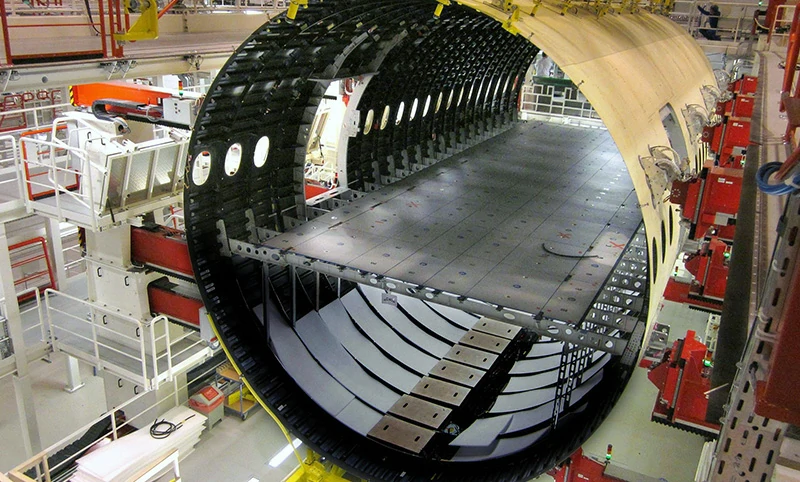

Applications: aircraft structures, military vehicles, weapons, and truck frames.

2017 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| F | 310-380 | 140-200 | 95-105 | 10-15 | 49.3 | Fair | Fair | Fair |

| O | 240-330 | 110-170 | 75-85 | 15-20 | 50 | Fair | Good | Good |

| T4 | 370-450 | 220-300 | 100-120 | 12-18 | 34 | Fair | Fair | Fair |

Applications: high-strength structural components, aircraft, mechanical structures, screw machine products, rivets, and roller skates.

2024 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| F | 250-450 | 115-310 | 80-120 | 10-20 | 46.8 - 48.5 | Poor | Poor | Fair |

| O | 140-250 | 65-140 | 40-60 | 18-25 | 50 | Fair | Good | Good |

| T3 | 400-470 | 270-330 | 120-130 | 10-15 | 28.6-36.1 | Poor | Fair | Fair |

| T351 | 400-470 | 260-320 | 120-130 | 10-16 | 30 | Poor | Fair | Fair |

| T4 | 370-450 | 255-315 | 110-120 | 15-20 | 28-31 | Poor | Fair | Fair |

| T6 | 450-520 | 375-450 | 130-140 | 8-12 | 38 | Poor | Poor | Fair |

| T851 | 455-505 | 380-450 | 130-140 | 10-12 | 38 | Poor | Fair | Fair |

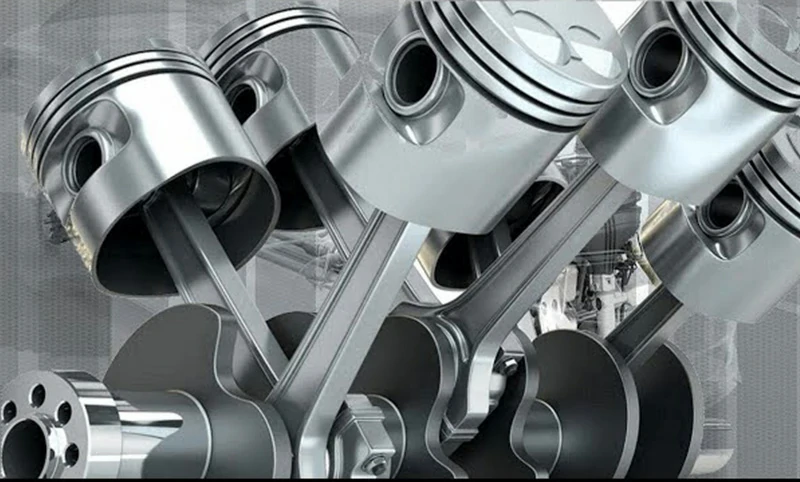

Applications: wing and fuselage structures, truck wheels, nuts, pistons, and gears.

2124 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 220-360 | 110-170 | 60-85 | 15-20 | 50 | Fair | Good | Good |

| T851 | 470-520 | 400-450 | 120-140 | 9-12 | 39 | Poor | Fair | Fair |

Applications: wing skins, fuselage skins, and high-performance military aircraft.

2219 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 170-260 | 70-140 | 60-80 | 16-22 | 44 | Fair | Good | Good |

| T6 | 400-470 | 290-350 | 110-130 | 10-14 | 30 | Poor | Fair | Fair |

| T62 | 420-480 | 310-370 | 115-135 | 8-12 | 30 | Poor | Fair | Fair |

| T851 | 470-530 | 390-450 | 130-150 | 8-12 | 30 | Poor | Fair | Fair |

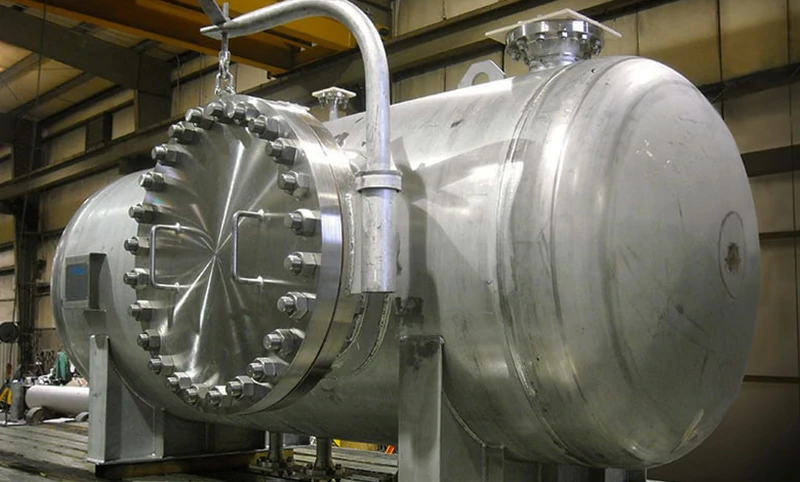

Applications: high-temperature structural uses, including space boosters and fuel tanks..

2618 aluminum alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

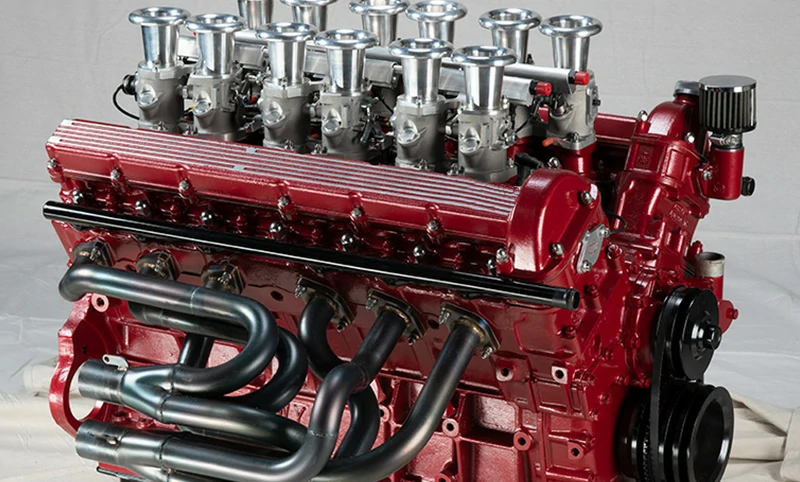

Applications: aerospace pistons and rotating aircraft components, as well as automotive pistons.

The performance of 3000 series aluminum alloys

The Al-Mn non-heat-treatable alloys 3003 and 3004 are representatives of this series. The addition of Mn increases strength by 10-20% compared to the 1000 Series alloys, and they also have excellent deep drawability.

3003

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 95-135 | 35-70 | 30-40 | 20-30 | 50 | Excellent | Excellent | Excellent |

| H12 | 125-160 | 105-135 | 35-50 | 12-17 | 42 | Excellent | Excellent | Excellent |

| H14 | 140-180 | 120-150 | 40-55 | 10-15 | 41 | Excellent | Excellent | Excellent |

| H18 | 165-205 | 145-175 | 50-60 | 4-8 | 40 | Excellent | Excellent | Excellent |

| H24 | 145-185 | 115-145 | 45-55 | 10-16 | 37.8-47.5 | Excellent | Excellent | Excellent |

| H28 | 160-200 | 135-165 | 50-60 | 6-10 | 37.8-47.5 | Excellent | Excellent | Excellent |

Applications: cookware, food containers, chemical equipment, pressure vessels, cans, and cabinets.

3004

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 130-185 | 55-90 | 35-45 | 15-20 | 42 | Excellent | Excellent | Excellent |

| H19 | 240-285 | 210-255 | 60-75 | 2-5 | 38 | Excellent | Fair | Good |

Applications: beverage cans, automotive parts, and storage tanks.

3105

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 110-145 | 50-85 | 40-50 | 15-25 | 45 | Excellent | Excellent | Excellent |

| H14 | 150-180 | 120-145 | 50-60 | 8-12 | 41 | Excellent | Excellent | Excellent |

| H24 | 145-175 | 110-135 | 50-60 | 10-16 | 41 | Excellent | Excellent | Excellent |

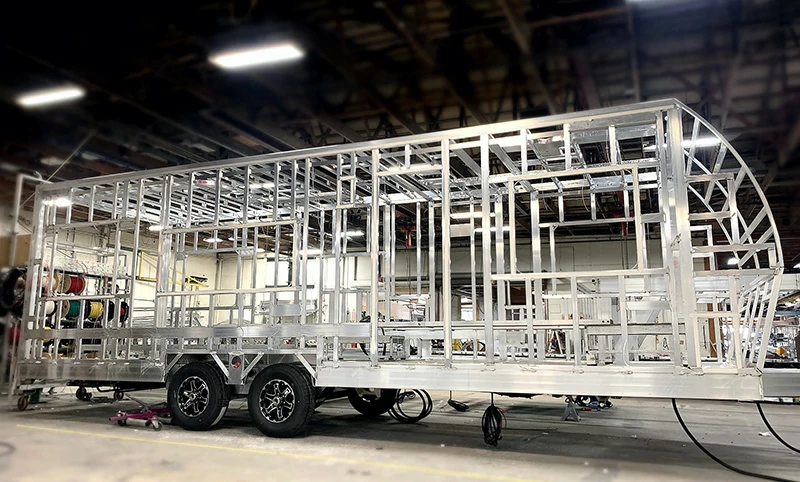

Applications: residential exteriors, sign making, and mobile homes.

The performance of 4000 series aluminum alloys

Silicon provides this aluminum alloy with excellent fluidity when molten and minimal shrinkage upon solidification, making it ideal for casting. It offers good machinability, corrosion resistance, and moderate strength.

4032

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Electrical Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 200-300 | 120-200 | 75-90 | 15-20 | 40 | Good | Poor | Fair |

| T6 | 350-400 | 290-320 | 120-130 | 6-10 | 36 | Fair | Poor | Fair |

Applications: racing engine components, pistons, and chassis parts.

4047

| Tensile Strength | Yield Strength | Hardness | Elongation | Conductivity(%IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| 120 MPa | 64MPa | 40-60 HB | 3.4% | 33% | Good | Excellent | Good |

The performance of 5000 series aluminum alloys

The 5000 series aluminum alloys are primarily alloyed with magnesium. They are commonly used in vehicles, pressurized vessels, and bridges. Aluminum 5052 is especially popular for bent sheet metal parts.

5005

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| H14 | 165-205 | 130-160 | 55-65 | 8-15 | 52 | Excellent | Good | Good |

| H32 | 165-215 | 130-185 | 55-65 | 10-16 | 52 | Excellent | Good | Good |

| H34 | 175-225 | 140-195 | 60-70 | 10-14 | 52 | Excellent | Good | Good |

Applications: roofing, cladding and corrugated panels, signs, road signs, and nameplates.

5052

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 170-230 | 70-100 | 45-55 | 20-30 | 35 | Excellent | Excellent | Good |

| H14 | 210-260 | 140-190 | 55-65 | 12-18 | 35 | Excellent | Good | Good |

| H32 | 210-260 | 145-195 | 55-65 | 10-16 | 35 | Excellent | Good | Good |

| H34 | 230-280 | 175-225 | 60-70 | 10-15 | 35 | Excellent | Good | Good |

| H38 | 240-290 | 185-235 | 65-75 | 8-12 | 35 | Excellent | Good | Good |

| H39 | 250-300 | 195-245 | 70-80 | 6-10 | 35 | Excellent | Good | Good |

| H111 | 180-230 | 90-130 | 50-60 | 15-25 | 35 | Excellent | Good | Good |

Applications: aircraft fuel and oil lines, hydraulic tubes, and heat exchangers.

5056

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Electrical Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 240-290 | 110-150 | 70-80 | 20-30 | 29 | Excellent | Good | Good |

| H32 | 260-310 | 175-220 | 75-85 | 15-20 | 28 | Excellent | Good | Good |

| H38 | 270-320 | 185-230 | 80-90 | 10-15 | 27 | Excellent | Good | Good |

Applications: zippers, cable sheathing, magnesium rivets, and screen wire.

5083

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 275-320 | 125-175 | 70-85 | 16-25 | 29 | Excellent | Excellent | Good |

| H22 | 305-355 | 175-225 | 75-90 | 12-20 | 29 | Excellent | Good | Good |

| H32 | 310-360 | 185-235 | 75-90 | 10-18 | 29 | Excellent | Good | Good |

| H34 | 320-370 | 195-245 | 80-95 | 8-15 | 29 | Excellent | Good | Good |

| H111 | 290-335 | 150-200 | 70-85 | 15-25 | 29 | Excellent | Good | Good |

| H112 | 305-350 | 175-225 | 75-90 | 12-22 | 29 | Excellent | Good | Good |

| H116 | 320-370 | 195-245 | 80-95 | 8-15 | 29 | Excellent | Good | Good |

| H321 | 315-365 | 185-235 | 75-90 | 10-20 | 29 | Excellent | Good | Good |

Applications: pressure vessels, dump truck bodies, rail cars, shipbuilding, vehicle bodies, and mine skips.

5086

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| H32 | 290-340 | 185-235 | 75-90 | 10-18 | 31 | Excellent | Good | Good |

| H111 | 280-330 | 150-200 | 70-85 | 15-25 | 31 | Excellent | Good | Good |

| H116 | 300-350 | 195-245 | 80-95 | 8-15 | 31 | Excellent | Good | Good |

Applications: missile components, unlaunched and welded pressure vessels.

5182

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 170-250 | 60-110 | 50-60 | 20-30 | 31 | Excellent | Good | Good |

| H19 | 220-270 | 140-170 | 55-65 | 12-18 | 31 | Excellent | Good | Good |

| H32 | 230-280 | 160-210 | 60-70 | 10-15 | 31 | Excellent | Good | Good |

| H34 | 240-290 | 170-220 | 65-75 | 8-12 | 31 | Excellent | Good | Good |

| H111 | 200-260 | 120-160 | 55-65 | 15-25 | 31 | Excellent | Good | Good |

Applications: beverage cans, packaging products, and automotive parts including hoods, doors, and fenders.

5454

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| H32 | 275-325 | 180-230 | 70-80 | 10-15 | 34 | Excellent | Good | Good |

| H34 | 290-340 | 195-245 | 75-85 | 8-12 | 34 | Excellent | Good | Good |

| H111 | 250-300 | 160-210 | 65-75 | 15-25 | 34 | Excellent | Good | Good |

Applications: cryogenic engineering, marine and offshore engineering, towers, poles and masts, as well as pressure vessels, containers, and boilers.

5456

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| H116 | 310-360 | 220-270 | 75-85 | 10-15 | 29 | Excellent | Good | Good |

| H321 | 300-350 | 200-250 | 70-80 | 12-20 | 29 | Excellent | Good | Good |

5754

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| H12 | 250-300 | 150-200 | 65-75 | 15-25 | 33 | Excellent | Good | Good |

| H14 | 260-310 | 160-210 | 70-80 | 12-20 | 33 | Excellent | Good | Good |

| H22 | 270-320 | 170-220 | 75-85 | 10-15 | 33 | Excellent | Good | Good |

| H111 | 240-290 | 140-190 | 65-75 | 15-25 | 33 | Excellent | Good | Good |

Applications: footboards, vehicle bodies, fishing gear, and external and component parts of ships.

The performance of 6000 series aluminum alloys

Featuring both magnesium and silicon as the main alloying elements, this series of metals offers good strength, resistance to atmospheric corrosion, and are machinable.

6005

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T5 | 180-250 | 110-160 | 50-70 | 8-12 | 49 | Good | Good | Good |

| T6 | 250-290 | 160-210 | 60-75 | 10-15 | 54 | Excellent | Good | Good |

| T61 | 260-300 | 170-220 | 65-80 | 8-12 | 54 | Excellent | Fair | Good |

Applications: furniture tubing, rail and bus profile structures, towers, platforms and pipelines, and portable ladders.

6060

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T4 | 160-220 | 110-150 | 45-60 | 10-20 | 54 | Good | Good | Good |

| T5 | 180-230 | 130-180 | 50-65 | 8-15 | 54 | Good | Good | Good |

| T51 | 180-230 | 130-180 | 50-65 | 10-15 | 54 | Good | Good | Good |

| T6 | 230-290 | 170-220 | 60-75 | 8-12 | 54 | Excellent | Good | Good |

Applications: window frames, doors, curtain walls, interior decoration, lighting, furniture, and architectural profiles for office equipment.

6061

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 120-170 | 55-95 | 30-45 | 20-25 | 47 | Excellent | Excellent | Good |

| T4 | 180-240 | 110-160 | 50-65 | 14-20 | 40 | Good | Excellent | Good |

| T5 | 240-300 | 200-250 | 75-85 | 8-12 | 41 | Good | Good | Good |

| T6 | 260-310 | 240-280 | 85-95 | 6-12 | 43 | Excellent | Good | Good |

| T651 | 270-320 | 240-280 | 85-95 | 6-12 | 43 | Excellent | Good | Good |

| T6511 | 260-290 | 240-270 | 85-95 | 6-12 | 43 | Excellent | Good | Good |

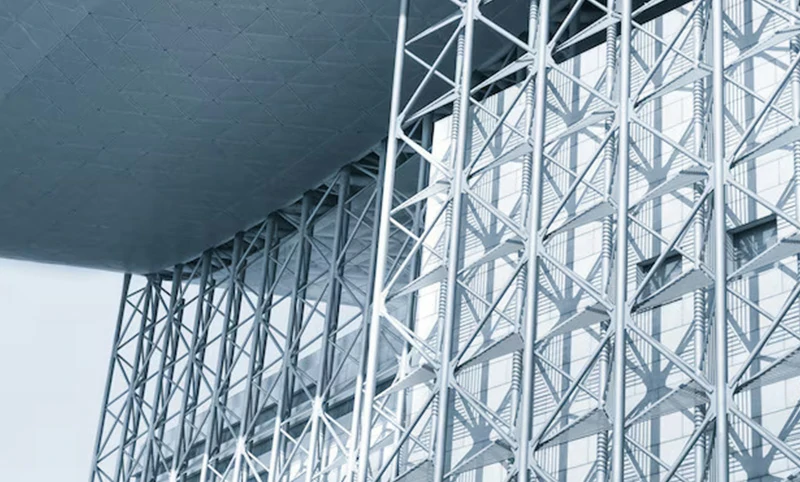

Applications: building frames, bridges, and trusses.

6062

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T4 | 190-240 | 110-160 | 50-65 | 14-20 | 43.5 - 44 | Good | Excellent | Good |

| T6 | 260-310 | 240-280 | 85-95 | 8-12 | 44.7 - 49.5 | Excellent | Good | Good |

Applications: jet bridges, luggage carts, and hand trucks.

6063

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T3 | 150-200 | 110-150 | 45-60 | 12-18 | 50-55 | Excellent | Excellent | Good |

| T4 | 130-180 | 80-130 | 45-55 | 16-24 | 49 | Excellent | Excellent | Good |

| T5 | 160-210 | 120-160 | 50-65 | 8-12 | 55 | Excellent | Good | Good |

| T52 | 160-210 | 120-160 | 50-65 | 8-12 | 53 | Excellent | Good | Good |

| T6 | 205-245 | 180-215 | 70-80 | 8-12 | 53 | Excellent | Good | Good |

| T66 | 240-260 | 200-230 | 75-85 | 6-10 | 53 | Excellent | Good | Good |

| T83 | 260-280 | 230-250 | 80-90 | 6-10 | 53 | Excellent | Good | Good |

Applications: construction, extrusions, window frames, and doors.

6066

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 240-290 | 150-190 | 75-85 | 16-20 | 40 | Good | Excellent | Good |

| T4 | 350-390 | 240-270 | 95-105 | 10-15 | 40 | Good | Good | Good |

| T6 | 420-470 | 360-410 | 110-120 | 8-12 | 37 | Excellent | Good | Good |

| T651 | 420-470 | 360-410 | 110-120 | 8-12 | 37 | Excellent | Good | Good |

Applications: forged and extruded components for welded structures.

6101

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T6 | 260-300 | 240-270 | 80-90 | 8-12 | 57 | Excellent | Good | Good |

| T61 | 250-290 | 230-260 | 75-85 | 9-13 | 59 | Excellent | Good | Good |

| T63 | 270-310 | 250-280 | 80-90 | 8-12 | 58 | Excellent | Good | Good |

| T64 | 265-305 | 245-275 | 80-90 | 8-12 | 60 | Excellent | Good | Good |

| T65 | 275-315 | 255-285 | 85-95 | 7-11 | 58 | Excellent | Good | Good |

Applications: electrical bus conductors and fittings, power transmission, and electrical components.

6951

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 200-240 | 90-120 | 60-75 | 14-18 | 35-40 | Good | Excellent | Good |

| T6 | 370-410 | 330-370 | 105-115 | 6-10 | 30-35 | Very Good | Good | Good |

Applications: construction, transportation, and general engineering.

The performance of 7000 series aluminum alloys

This is a heat-treatable alloy with zinc and smaller amounts of copper, magnesium, and other elements. It has high strength, good toughness, and fatigue and corrosion resistance.

7003

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T5 | 270-320 | 220-270 | 70-90 | 10-12 | 36 | Good | Fair | Good |

| T6 | 340-390 | 290-340 | 85-105 | 8-10 | 36 | Very Good | Fair | Good |

Applications: scaffolding components, mobile cranes, elevators, and air cargo containers.

7005

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 220-280 | 110-150 | 60-80 | 12-16 | 43 | Good | Excellent | Good |

| T53 | 350-410 | 300-360 | 95-105 | 8-12 | 38 | Very Good | Good | Good |

| T5351 | 350-410 | 300-360 | 95-105 | 8-12 | 38 | Very Good | Good | Good |

| T6 | 400-450 | 330-390 | 105-115 | 7-10 | 35 | Very Good | Good | Good |

| T63 | 390-450 | 330-390 | 105-115 | 7-10 | 38 | Very Good | Good | Good |

| T6351 | 390-450 | 330-390 | 105-115 | 7-10 | 38 | Very Good | Good | Good |

Applications: bicycle or car frames, and automotive parts.

7039

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 250-310 | 130-180 | 70-80 | 14-18 | 32-35 | Good | Fair | Good |

| T61 | 340-390 | 290-340 | 85-105 | 8-10 | 30-32 | Very Good | Fair | Good |

| T64 | 350-400 | 300-350 | 90-110 | 7-9 | 30-32 | Very Good | Fair | Good |

Applications: refrigerated containers, cryogenic equipment, storage tanks, fire pressure equipment, military gear, armor plates, and missile systems.

7049

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T352 | 510-570 | 460-510 | 120-150 | 8-10 | 40 | Good | Poor | Good |

| T73 | 470-540 | 420-470 | 100-130 | 8-10 | 36 | Very Good | Poor | Good |

| T7352 | 490-550 | 440-490 | 110-140 | 6-8 | 36 | Very Good | Poor | Good |

Applications: structural forgings, particularly in the missile or aerospace industries, aircraft structural components, and missile parts.

7050

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 310-380 | 160-220 | 70-85 | 15-20 | 47 | Good | Fair | Good |

| T6 | 460-530 | 400-460 | 90-105 | 8-10 | 42 | Very Good | Fair | Good |

| T736 | 440-500 | 350-410 | 100-115 | 8-10 | 40.5 | Very Good | Fair | Good |

| T73651 | 440-500 | 350-410 | 100-115 | 8-10 | 40.5 | Very Good | Fair | Good |

| T74 | 490-550 | 400-450 | 105-120 | 6-8 | 40 | Excellent | Poor | Good |

| T7451 | 490-550 | 400-450 | 105-120 | 6-8 | 40 | Excellent | Poor | Good |

| T76 | 500-570 | 420-480 | 110-125 | 5-7 | 39.5 | Excellent | Poor | Good |

| T7651 | 500-570 | 420-480 | 110-125 | 5-7 | 39.5 | Excellent | Poor | Good |

Applications: aircraft and other structures, fuselage frames, cabin walls, and wing skins.

7075

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| T6 | 510-570 | 430-510 | 150-180 | 5-10 | 32 | Good | Poor | Good |

| T62 | 490-540 | 400-450 | 140-160 | 7-10 | 33 | Good | Poor | Good |

| T651 | 510-570 | 430-510 | 150-180 | 5-10 | 33 | Good | Poor | Good |

| T652 | 510-570 | 430-510 | 150-180 | 5-10 | 33 | Good | Poor | Good |

| T76 | 520-580 | 440-520 | 160-190 | 5-8 | 38.5 | Excellent | Poor | Good |

| T7651 | 520-580 | 440-520 | 160-190 | 5-8 | 38.5 | Excellent | Poor | Good |

| T73 | 450-510 | 350-420 | 130-150 | 8-12 | 40 | Very Good | Fair | Good |

| T7351 | 450-510 | 350-420 | 130-150 | 8-12 | 40 | Very Good | Fair | Good |

| T7352 | 450-510 | 350-420 | 130-150 | 8-12 | 40 | Very Good | Fair | Good |

Applications: aircraft components, gears and shafts, missile parts, control valve components, and worm gears.

7175

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 310-380 | 160-220 | 70-85 | 15-20 | 46 | Good | Fair | Good |

| T66 | 480-550 | 400-470 | 120-140 | 8-10 | 36 | Very Good | Fair | Good |

| T73 | 460-510 | 350-420 | 110-130 | 10-12 | 40 | Very Good | Fair | Good |

| T736 | 490-540 | 400-470 | 130-150 | 8-10 | 40 | Excellent | Poor | Good |

| T73652 | 490-540 | 400-470 | 130-150 | 8-10 | 40 | Excellent | Poor | Good |

| T74 | 510-570 | 420-480 | 140-160 | 6-8 | 33 | Excellent | Poor | Good |

Applications: structural uses and fittings, including bolts and rivets.

7178

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Electrical Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 310-380 | 160-220 | 70-85 | 15-20 | 46 | Good | Fair | Good |

| T6 | 510-580 | 430-510 | 150-180 | 5-8 | 32 | Good | Poor | Good |

| T651 | 510-580 | 430-510 | 150-180 | 5-8 | 32 | Good | Poor | Good |

| T76 | 520-580 | 450-510 | 160-190 | 5-8 | 39 | Excellent | Poor | Good |

| T7651 | 520-580 | 450-510 | 160-190 | 5-8 | 39 | Excellent | Poor | Good |

Applications: Aircraft components, petroleum refineries, boilers, heat exchangers, pipelines, cooling towers.

7475

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 310-380 | 160-220 | 70-85 | 15-20 | 46 | Good | Fair | Good |

| T61 | 460-510 | 350-420 | 110-130 | 8-10 | 36 | Very Good | Fair | Good |

| T651 | 460-510 | 350-420 | 110-130 | 8-10 | 36 | Very Good | Fair | Good |

| T76 | 490-550 | 400-470 | 130-150 | 6-8 | 40 | Excellent | Poor | Good |

| T761 | 490-550 | 400-470 | 130-150 | 6-8 | 40 | Excellent | Poor | Good |

| T7651 | 490-550 | 400-470 | 130-150 | 6-8 | 40 | Excellent | Poor | Good |

| T7351 | 450-510 | 350-420 | 130-150 | 8-12 | 42 | Very Good | Fair | Good |

Applications: Fusels, wing skins, structural aerospace components and highly stressed parts.

The performance of 8000 series aluminum alloys

The 8000 series aluminum alloys are a group of alloys primarily used for applications requiring a mix of strength, corrosion resistance, and specific properties. They are often alloyed with elements like copper, nickel, or iron. Common uses include food packaging, electrical cables, and heat exchangers.

8006

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 110-145 | 55-95 | 30-45 | 10-16 | 40 | Excellent | Good | Good |

| H12 | 170-210 | 130-170 | 45-55 | 4-10 | 38 | Excellent | Fair | Good |

| H14 | 190-230 | 150-190 | 50-60 | 3-7 | 36 | Excellent | Fair | Good |

| H18 | 220-260 | 180-220 | 55-70 | 2-5 | 36 | Excellent | Fair | Good |

Applications: food packaging, microelectronics, and heat exchanger fins.

8011

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 85-110 | 30-50 | 20-30 | 25-35 | 56 | Excellent | Excellent | Good |

| H14 | 120-150 | 90-120 | 35-45 | 4-8 | 52 | Excellent | Fair | Good |

| H22 | 135-165 | 110-140 | 45-55 | 2-4 | 48 | Excellent | Fair | Good |

| H24 | 145-175 | 125-155 | 50-60 | 1-3 | 48 | Excellent | Fair | Good |

Applications: liquor bottle caps, wine caps, cosmetic caps, milk powder caps, pharmaceutical caps, beverage caps, and yogurt caps.

8079

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Conductivity (% IACS) | Corrosion Resistance | Weldability | Surface Treatment |

| O | 90-130 | 35-90 | 20-35 | 15-25 | 34-37 | Excellent | Good | Excellent |

| H14 | 130-180 | 110-145 | 40-50 | 1-4 | 32-36 | Good | Fair | Good |

| H18 | 140-180 | 125-155 | 45-55 | 1-3 | 30-35 | Good | Fair | Good |

Applications: food packaging, beer labels, household foil, and bottle caps.