6082 aluminum alloy is the highest-strength alloy in the 6000 series, known for its excellent corrosion resistance, machinability, and anodizing properties, and is considered a structural alloy.

Mastar offers 6082 aluminum round bars with diameters ranging from 0.1 inches (3mm) to 54 inches (1350mm), available in various tempers such as T4, T6, T651, and T6511, and compliant with EN 573-3 and EN 755-2 standards.

6082 aluminum bar specifications

- EN 573-3,EN 755-1,EN 755-2,EN 754

- BS L100,BS L111

- DTD 936

- H30TF

- ASTM B221

6082 aluminum bar size range

Our products include various 6082 aluminum round bars, 6082 aluminum square bars, 6082 aluminum hex bars, 6082 large diameter aluminum bars, and 6082 forged bars.

- 6082 aluminum round bar

Diameter: 0.2-14 in

- 6082 aluminum square bar

Diameter: 0.2-8 in

- 6082 aluminum flat bar

Diameter: 0.2-4 in

- 6082 aluminum hexagonal bar

Diameter: 0.2-14 in

- 6082 aluminum forged bar

Diameter: 0.2-26 in

- Large diameter aluminum bar

Diameter: 5-54 in

In addition to 6082 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

Popular stock sizes of 6082 aluminum round bar

Mastar stocks 6082 aluminum bars in various sizes and tempers including T4, T6, T651, and T6511.

We offer aluminum bars in lengths ranging from 1 meter to 6 meters and can cut them to any length you need at no extra charge.Quick Quote

Stock sizes of 6082 T6 aluminum round bar

| Specification | Diameter (mm) | Diameter (inches) | Weight (lbs/foot) |

| 6082-T6 aluminum round bar | 6 | 0.236 | 0.051 |

| 6082-T6 aluminum round bar | 8 | 0.315 | 0.091 |

| 6082-T6 aluminum round bar | 10 | 0.394 | 0.142 |

| 6082-T6 aluminum round bar | 14 | 0.551 | 0.279 |

| 6082-T6 aluminum round bar | 16 | 0.630 | 0.365 |

| 6082-T6 aluminum round bar | 18 | 0.709 | 0.461 |

| 6082-T6 aluminum round bar | 20 | 0.787 | 0.570 |

| 6082-T6 aluminum round bar | 25 | 0.984 | 0.890 |

| 6082-T6 aluminum round bar | 35 | 1.378 | 1.745 |

| 6082-T6 aluminum round bar | 40 | 1.575 | 2.279 |

| 6082-T6 aluminum round bar | 45 | 1.772 | 2.884 |

| 6082-T6 aluminum round bar | 50 | 1.969 | 3.560 |

| 6082-T6 aluminum round bar | 55 | 2.165 | 4.309 |

| 6082-T6 aluminum round bar | 65 | 2.559 | 6.018 |

| 6082-T6 aluminum round bar | 70 | 2.756 | 6.979 |

| 6082-T6 aluminum round bar | 75 | 2.953 | 8.012 |

| 6082-T6 aluminum round bar | 85 | 3.346 | 10.290 |

| 6082-T6 aluminum round bar | 105 | 4.133 | 15.703 |

| 6082-T6 aluminum round bar | 110 | 4.330 | 17.234 |

| 6082-T6 aluminum round bar | 120 | 4.724 | 20.510 |

| 6082-T6 aluminum round bar | 130 | 5.118 | 24.071 |

| 6082-T6 aluminum round bar | 135 | 5.315 | 25.958 |

| 6082-T6 aluminum round bar | 150 | 5.906 | 32.047 |

| 6082-T6 aluminum round bar | 160 | 6.299 | 36.463 |

| 6082-T6 aluminum round bar | 210 | 8.268 | 62.813 |

| 6082-T6 aluminum round bar | 230 | 9.055 | 75.347 |

| 6082-T6 aluminum round bar | 250 | 9.843 | 89.020 |

| 6082-T6 aluminum round bar | 260 | 10.236 | 96.284 |

| 6082-T6 aluminum round bar | 310 | 12.205 | 136.877 |

| 6082-T6 aluminum round bar | 320 | 12.598 | 145.850 |

Stock sizes of 6082 T651 aluminum round bar

| Specification | Diameter (mm) | Diameter (inches) | Weight (lbs/foot) |

| 6082-T651 aluminum round bar | 20 | 0.787 | 0.570 |

| 6082-T651 aluminum round bar | 30 | 1.181 | 1.281 |

| 6082-T651 aluminum round bar | 60 | 2.362 | 5.128 |

| 6082-T651 aluminum round bar | 80 | 3.150 | 9.116 |

| 6082-T651 aluminum round bar | 95 | 3.740 | 12.854 |

| 6082-T651 aluminum round bar | 100 | 3.937 | 14.243 |

| 6082-T651 aluminum round bar | 140 | 5.512 | 27.917 |

| 6082-T651 aluminum round bar | 170 | 6.693 | 41.163 |

| 6082-T651 aluminum round bar | 180 | 7.087 | 46.148 |

| 6082-T651 aluminum round bar | 190 | 7.480 | 51.418 |

| 6082-T651 aluminum round bar | 220 | 8.661 | 68.937 |

| 6082-T651 aluminum round bar | 270 | 10.630 | 103.833 |

| 6082-T651 aluminum round bar | 280 | 11.024 | 111.667 |

If you don't see what you're looking for, please contact our customer service and provide your specific requirements.Quick Quote

6082 aluminum bar chemical standards (EN 573-3)

The content of Si, Mg, and Mn elements in 6082 aluminum bars significantly affects their mechanical properties, coarse grain structure, and bending performance.

By controlling the chemical composition within a reasonable range, the product quality can be effectively improved.

| Chemical Element | Present % |

| Manganese (Mn) | 0.40 - 1.00 |

| Iron (Fe) | 0.0 - 0.50 |

| Magnesium (Mg) | 0.60 - 1.20 |

| Silicon (Si) | 0.70 - 1.30 |

| Copper (Cu) | 0.0 - 0.10 |

| Zinc (Zn) | 0.0 - 0.20 |

| Titanium (Ti) | 0.0 - 0.10 |

| Chromium (Cr) | 0.0 - 0.25 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

6082 aluminum bar mechanical properties (EN 755-2)

| Diameter | Up to 20mm Dia | 20mm to 150mm Dia | 150mm to 200mm Dia | 200mm to 250mm Dia |

| Proof Stress | 250 Min MPa | 260 Min MPa | 240 Min MPa | 200 Min MPa |

| Tensile Strength | 295 Min MPa | 310 Min MPa | 280 Min MPa | 270 Min MPa |

| Elongation A50 mm | 6 Min % | - | - | |

| Hardness Brinell | 95 HB | 95 HB | 95 HB | 95 HB |

| Elongation A | 8 Min % | 8 Min % | 6 Min % | 6 Min % |

6082 aluminum bar physical properties

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555°C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 0.038 x10^-6 Ω .m |

Strength performance of 6082 aluminum bar

6082 aluminum bar is one of the strongest alloys in the 6000 series. In T6 or T651 temper, it delivers excellent mechanical properties with tensile strength reaching up to 350 MPa and yield strength above 290 MPa.

This makes it a reliable material for structural components subjected to high loads, such as truck frames, bridges, cranes, and machined mechanical parts.Compared with standard alloys like 6061 or 6063, 6082 offers significantly better strength while still maintaining good corrosion resistance and weldability.

For applications requiring similar or even higher strength performance, the following aluminum bar alloys are also recommended:

How we address coarse grain ring issues in 6082 aluminum bars

The presence of coarse grain rings can significantly reduce the mechanical properties of aluminum bars. To address this issue, we implement a series of measures:

- Addition of Recrystallization Inhibiting Elements: We incorporate elements such as Mn, Cr, Sc, and Zr into the alloy. These elements form fine dispersed phases that prevent grain growth, thereby reducing the formation of coarse grain rings.

- Reverse Extrusion: Reverse extrusion helps reduce the formation of coarse grain rings and improves the strength and toughness of the aluminum material.

- Homogenization Heat Treatment: Through homogenization heat treatment, we achieve a more uniform distribution of dispersed phases, further reducing coarse grain rings.

- Optimization of Extrusion and Heat Treatment Processes: We have optimized the extrusion process, solution heat treatment process, and die structure to suppress the occurrence of coarse grain rings.

Does the strength of 6082 aluminum bar decrease after welding?

Yes, welding 6082 aluminum bars can reduce the material's strength. We recommend using 4043 welding wire when welding 6082 aluminum bars. If welding 6082 to 7005, use 5356 welding wire. Finally, aging treatment and machining can restore the strength of the welded 6082 aluminum bars.

Additionally, friction stir welding is an effective method for handling 6082 aluminum alloy. It provides high-quality weld joints with a reduced heat-affected zone, significantly improving welding strength.

Of course, we can assist with these steps and are happy to provide any help you need.Quick Quote

Equivalent names for 6082 aluminum bar

6082 aluminum alloy is also referred to by the following standard names and specifications, though they may not be directly equivalent:

- HE30

- DIN 3.2315

- AFNOR 6082

- UNI 6082

- EN AW-6082

- ISO:Al Si1MgMn

- AA6082

- A96082

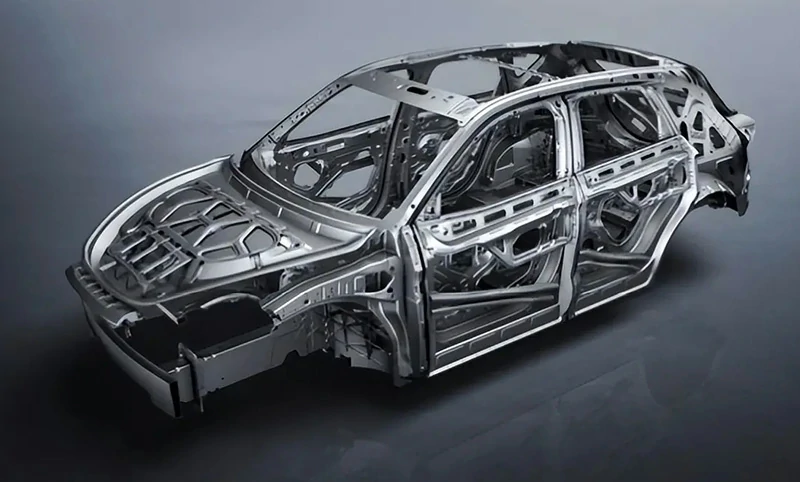

Applications of 6082 aluminum bar

- Mechanical Manufacturing: Mechanical components, high-strength aluminum shafts, aluminum brackets

- Construction Engineering: Aluminum alloy door and window frames, building aluminum supports

- Automotive Industry: Aluminum alloy body structures, automotive aluminum support structures

- Shipbuilding: Aluminum bars for ships, corrosion-resistant aluminum alloys, aluminum structural components for hulls

- Aerospace: Aircraft structural components, aerospace aluminum alloy parts, high-strength aluminum alloy parts

- Sports Equipment: Sports equipment, bicycle frames, lightweight aluminum sports gear, skiing equipment

- Power Industry: Transmission towers, distribution boxes, aluminum structures for power equipment